That's the problem, you should not

measure the tangent. You should measure the thing that can be measured (the bevel), calculate the curvature of the bevel, then

calculate the tangent at the relevant point (the apex).

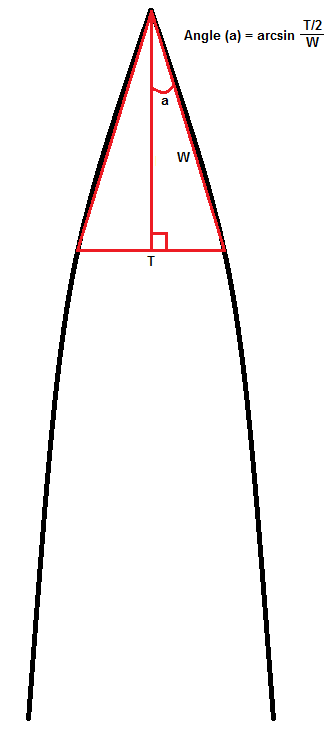

I was able to redo this on Inventor, here is an image of the Gillette example.

Not "should not", you CANNOT measure the tangent,

it doesn't exist, it is purely

theoretical and

impossible in reality. A "tangent" can only

just touch the curve, meeting it at a

single point, a "point" being utterly dimensionless = theoretical, not real. To use the wikipedia description:

The intuitive notion that a tangent line "touches" a curve can be made more explicit by considering the sequence of straight lines (secant lines) passing through two points, A and B, those that lie on the function curve. The tangent at A is the limit when point B approximates or tends to A. The existence and uniqueness of the tangent line depends on a certain type of mathematical smoothness, known as "differentiability." For example, if two circular arcs meet at a sharp point (a vertex) then there is no uniquely defined tangent at the vertex because the limit of the progression of secant lines depends on the direction in which "point B" approaches the vertex.

It has already been made clear that curves do not have "angles" per-say, angles are

only achieved between straight lines, hence the need to derive a tangent (a straight line) with a defined

slope (i.e. angle) through a complex mathematical equation, the

derivative which I presented earlier:

It seems that any individual describing convex as "thinner than flat" understands neither English nor Math, and I am an expert of neither. In English, convex means to curve "out from" the associated flat, so any flat than the curve does NOT curve "out from" is NOT the associated flat. To

HH, you are not "cheating" by drawing another line beneath the flat line, you are failing to grasp the definition of the word "convex" itself.

To clarify the math aspect, the ONLY way to accurately describe the angle of a convex edge IS by measuring the bevel's height and thickness and calculating as I already presented numerous times.

Why is this the

only way? 1) the definition of the term "convex", and 2) the real-world limitations of "limits" via mathematical derivatives.

bpeezer has graciously plugged a series of measurements into a computer program which extrapolates a "best-fit" curve to the data points, generating an equation of the curve (a mathematical function) and deriving therefrom the radius of curvature as well as the limit of a secant-line through points A & B which lay upon that curve ('W' in my diagram),

the line necessarily passing beneath (thinner than) the curve. Understand that the tangent thus derived does not lay "above" the curve, it resides ON the curve at the point selected. *****

In relation to the tangent line, the curve is NOT "convex" at all as it does not meet the definition.***** The curve is only "convex" relative to the length 'W' between points A & B.

HOWEVER, the way in which the tangent line is arrived at, the derivation, depends

entirely on how close to the apex the measurements of thickness were taken, i.e. the measurement of bevel height and thickness, essentially the 'T' and 'W' presented in my diagram - and I use 'W' as the length of the hypotenuse (bevel width) because

one cannot practically measure the other length without taking a cross-section and so damaging the blade, it is an interior measurement whereas the bevel width is exterior and simple to measure.

'T' is relative to where 'W' is measured, and the tangent is derived from making 'W' as short as possible. 'T' and 'W' MUST BE FIXED measurements to derive the tangent of the curve, they are the data points. Cutting a NEW bevel that curves beneath W meeting only at the apex simply creates a NEW 'W' to be measured, hence why

HH's method fails to grasp reality. Now in order for

bpeezer's software to generate a best-fit equation, he required not just

one 'W' and 'T' but

multiple (at least three) heights and thicknesses

of measurable dimensions to input into the software. What if he'd had only one set, one 'T' and 'W', e.g. 0.4 microns back 0.25 from the apex? The data is insufficient for the software to generate a curve with any degree of accuracy. As I already pointed out, taking into account

the reality of limitations in apex size using steel,

the angle of that first bevel is 33.7 degrees per side - in front of that bevel, the steel rounds over to an apex of 90-dps with a diameter ~0.2 microns. Which is the "terminal angle" or even the "working angle" of the blade edge, the apex or the angle behind it? Or the angle behind that? Or the one behind that?? Just like the relative importance of the primary bevel angle to the edge angle, the answer depends on the material being cut and depth of penetration.

Backing up,

bpeezer ignored the apex-reality and used three measurements behind it to generate, via software, an equation that could produce a tangent at the apex of 38.7 dps. I ignored the apex and used ONLY that first measurement, did NOT generate a curve via software analysis (which I lack), and achieved almost the same exact angle! How is that possible? Because the software

guesses at thicknesses 'T' and bevel heights 'W' that

have not or

cannot be measured due to practical limitations, it produces

straight secant lines

falling beneath the curve with immeasurably small lengths 'W' and relying upon the equation generated also guesses immeasurably small thicknesses 'T' until it achieves a 'W' and a 'T' that are essentially

without lengths, only position and gives the slope of the line generated by a straight secant beneath the curve

one immeasurable step back from that.

Understand what I just told you? As previously stated, a 'point' where a tangent touches has no dimensions and so can present NO "angle" or slope for the tangent to possess, but

TWO POINTS form a secant-line

beneath the curve (which allows it to be called "convex" in relation to that secant) and so present a slope and angle. How long is that secant-line 'W'? For the software, it is immeasurably short since adjacent two-points are infinitesimally close so as to be indistinguishable except in mathematical fairy-land of the imagination. In the real-world, by using the smallest set of measurements available and producing a secant-line to the apex, we are not achieving the

theoretical limit of the angle as described by the tangent

because it does not exist, but present an approximation of the "working angle"

in the only reliable real-world method available.

To

HH, your of undercutting my 'W' with yet another curve fails utterly because the equation of THAT curve requires new measurements and new secant-lines to approximate a NEW bevel angle. It does NOT

in any way maintain the same "working angle" or "terminal angle" or whatever other term you may select to try to describe it. The "chase" you describe ONLY happens if you keep cutting new curves, which isn't necessary.

Now I read that many admit to only cutting off the shoulders of bevel-transitions and not actually curving all the way to the apex such that the approach to the apex is as flat as possible, whereupon the reality of my argument is even more obvious. By cutting down the shoulders, you create NEW transition bevels whose curvature can only be determined through flat-line measurements, just as Archimedes inscribed polygons in a circle to approximate the value of Pi.

Hopefully this is my last post on the topic, but i encourage all to recognize the definition of the word "convex" and the process of mathematically deriving the "angle" of a curve which relies heavily upon that definition being "curving outward from flat" - if the definition did NOT demand that convex being ALWAYS thicker than flat, the process of deriving a tangent at all would be

impossible.