-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edge Pro Apex 4 Vs Ruixin

- Thread starter Barmaley

- Start date

- Status

- Not open for further replies.

^Great to know. I'm narrowed down to EP Apex vs Hapstone, on the verge of getting one and it's points in the EP's favor that it looks like it handles low angles and small knives (with attachment) pretty well.

The Hapstone V8, with the movable outside table extensions removed, makes a goo small knife table. No extra attachment needed. It appears that low angles in the 10 to 12 degree area are possible. I've never wanted to sharpen that shallow. At least not yet.

The angle shown is between the blade table and the control arm. I know the actual angle sharpened onto the blade would be different, but I don't know by how much or in which direction.

O.B.

In the past @Blues warned me about asking repetitive questions; however, we all are different, and we may seek different level of usefulness and detalization of information we are looking to find. Sometimes I feel that I have to ask very same question if I did not get an answer I I am looking for. In this thread I am trying to figure out what exactly in terms of performance is the difference between Ruixin and Edge Pro? Reding the answer I realized that majority advice not to waste money on junk and while I comp;etely agree with that statement it does not help my research. In terms of specifics I saw two informative points: A) ruixin is not reliable and parts may fail to be replaces because it is make cheaply B) The workmanship of Edge pro is better (which make sense) and because of that you may get better sharpening (which need more elaboration - it what specific sense? Does Ruixin have lufts in joints so the sharpening angle is loose or what?)

One of the reasons I am asking is that I am considering to build a machine DIY and advice on what exactly make a machine better can save me a lot of time of correcting mistakes.

It can easily explained why Mercedes S-class is better than Chevy Impala not only in sense that it is “made better” but: a) is quieter, b) faster, c) safer etc. It would be nice if somebody could in more details explain what exactly Edge pro makes better for the end result. @kreisler gave very positive review of Ruixin and it would be interesting to learn what specifically wrong with Ruixin?

One of the reasons I am asking is that I am considering to build a machine DIY and advice on what exactly make a machine better can save me a lot of time of correcting mistakes.

It can easily explained why Mercedes S-class is better than Chevy Impala not only in sense that it is “made better” but: a) is quieter, b) faster, c) safer etc. It would be nice if somebody could in more details explain what exactly Edge pro makes better for the end result. @kreisler gave very positive review of Ruixin and it would be interesting to learn what specifically wrong with Ruixin?

The limitation of the angle is related to the construction of the device and the existence of knobs, screws or whatever that impede getting the stone in a more acute angle related to the blade. In some sharpeners the stone would hit the clamping knobs before the edge if you go too acute. In the Ruixin the clamping system is as flat as it could be, as it relies in countersunk screws (wrench provided) and the clamp itself is sheetmetal. Sometimes the thumbstuds are what gets in the way of the stone...

Mikel

Mikel

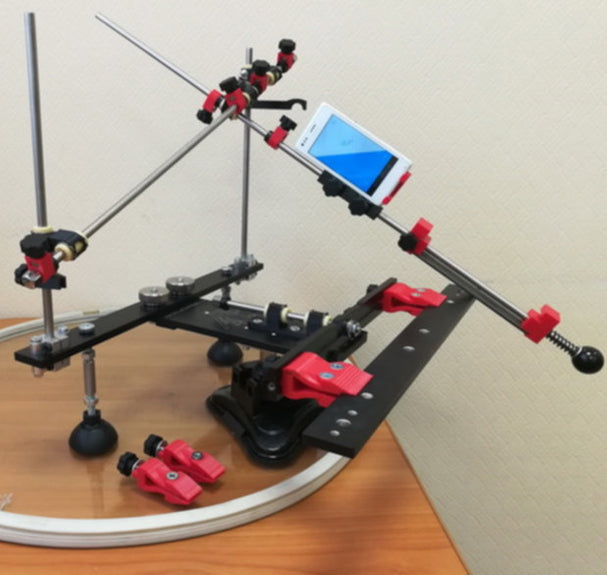

May I ask to provide your opinion on this machine:

I think it is the simplest machine I could find on the web. If my only goal is to make 12 degree angle +/- 1/4 of a degree - will it work?

I also like an idea of using bigger stones than Edge Pro standard. Did somebody try to use a stone arm similar to this video?

Regarding the second video - can somebody identify the oil stone which they use there?

I also like an idea of using bigger stones than Edge Pro standard. Did somebody try to use a stone arm similar to this video?

I also like an idea of using bigger stones than Edge Pro standard. Did somebody try to use a stone arm similar to this video?

Regarding the second video - can somebody identify the oil stone which they use there?

Now I understand where the Ruixin copied their clamp design from... blatant rip-off! BTW, the channel that allows to maintain the stone perpendicular to the edge totally eliminates the problem of changing the angle as you move from the middle of the blade to the tip or ricasso area. Genius! The trade off is that the system is quite bulky but... other than that, I like it a lot. EZESharp you said? Of I go to find one!

Mikel

To directly answer the OP's questions (sorry my other comment here was slightly O.T.  ):

):

I've been researching an affordable guided system recently to complement my freehand sharpening, which is probably 70% of my sharpening. But I also have some special case knives: large knives that are hard to sharpen, cheap knives I don't care about and I want to sharpen them really fast, or knives like a couple of nicer folders where I want to put a super consistent refined bevel. For any of those cases, that's that I want a guided system for, and I need something a little better than Sharpmaker that I've been using for years.

I settled on the E.P. Apex, just got mine and set it up yesterday for the first time. I can't tell you if it's "better" than a Ruixin mechanically speaking but there are 2 things I'm certain of: (1) the E.P. is an outstanding, time tested, quality piece of kit and you won't go wrong in buying it, and (2) you should not buy cheap crap from Chinese companies. Period. I won't buy anything from China when I have a choice. The Chinese CCP is a rotten communist dictatorship that rips off our tech, hurts our industries, abuses its own citizens (esp religious minorities and political dissidents, like Christians, Uighurs, and pro-democracy advocates), and works to undermine democracies all over the world (look at how it just ended democracy in Hong Kong, and is now working for the same goal in Taiwan). When you have a choice--clearly we don't always, some things like certain medications are made ONLY in China--and when you know where something is made: don't buy stuff from China. That's especially true when the item is simply a rip-off of American designs, as this Ruixin is, and hurts our people and companies. Buy American, or from friendly democratic countries. Get the E.P. Apex, get quality kit made in America or in one of our allied countries.

I appreciate @wootzblade and he knows his stuff, and agree in general that more acute angles are a good thing. I've been tending to use more acute angles on a lot of my knives. Though not all...I have some larger knives that are designed to do heavier work. There are cases where you need other types of edge angles IMO, and you want your sharpener to support that. Personally I wouldn't get a sharpening setup that can only handle one angle, it's not flexible enough for me. A specific example is I have 2 ESEE Junglas blades, one is 8", the other 10". These are designed for chopping and hacking, they are thick blade stock with tough carbon steel. But if I use super acute edges, the edges tend to chip and to roll more easily when I'm chopping tough wood or vines. I've actually tried a more acute edge at 14 dps on one of those, it didn't work well so I went back to 20 dps. I'm just basing that on observation of what happened to the edges, I don't have any fancy electron scanning microscope to show the details in the steel's molecules and all that. But I can just tell you what worked and what didn't at my place, with my knives. For knives doing work like that, also some of my heavy duty machetes and survival-type knives, I'd tend to go with a more obtuse edge up around 18 to 22 d.p.s. So yeah, I like using acute edges when it makes sense, and 12 to 14 dps is what I'm using now on a lot of my folders and some kitchen knives. But I also see a case for more obtuse angles on some knives. It all depends on how you're using them. You want your sharpener to be able to support multiple angles, for sure.

The new EP Apex is great: I got 2 attachments that help with various blades. The small blade adapter lets you sharpen teeny tiny like blades, like some of the small Swiss Army Knife blades included in some of their multitools, or small kitchen paring knives, etc. The Slide Guide attachment makes it easier to sharpen all types of knives in general, it gives you 2 or even 3 points of contact to help stabilize a knife in the right position while you're running a stone over the edge. With the adapters, I did a little testing last night, I took the small blade adapter and a very narrow bladed kitchen paring knife. I was able to sharpen it down to 12 dps, no problem, and there was room to go lower, checked it at 10 dps and could've easily sharpened to that angle using the attachments.

I'm pretty happy with the EP so far, only sharpened 2 knives but it looks like it'll do everything I need it to. OP, in addition to getting EP Apex, I'd look at the stone packages for it that Gritomatic offers, I got his Venev diamond stones, but he also has some nice sets such as a Silicon Carbide set of 5 stones that would probably help keep your initial cost down (if that's a concern), and the SiC stones will sharpen everything in your collection. Good luck with your decision!

I know that usually you get what you pay for. I also found that it is not always true. Edge Pro Apex 4 is ten times more than Ruixin. Does it really work better and in which way?

I've been researching an affordable guided system recently to complement my freehand sharpening, which is probably 70% of my sharpening. But I also have some special case knives: large knives that are hard to sharpen, cheap knives I don't care about and I want to sharpen them really fast, or knives like a couple of nicer folders where I want to put a super consistent refined bevel. For any of those cases, that's that I want a guided system for, and I need something a little better than Sharpmaker that I've been using for years.

I settled on the E.P. Apex, just got mine and set it up yesterday for the first time. I can't tell you if it's "better" than a Ruixin mechanically speaking but there are 2 things I'm certain of: (1) the E.P. is an outstanding, time tested, quality piece of kit and you won't go wrong in buying it, and (2) you should not buy cheap crap from Chinese companies. Period. I won't buy anything from China when I have a choice. The Chinese CCP is a rotten communist dictatorship that rips off our tech, hurts our industries, abuses its own citizens (esp religious minorities and political dissidents, like Christians, Uighurs, and pro-democracy advocates), and works to undermine democracies all over the world (look at how it just ended democracy in Hong Kong, and is now working for the same goal in Taiwan). When you have a choice--clearly we don't always, some things like certain medications are made ONLY in China--and when you know where something is made: don't buy stuff from China. That's especially true when the item is simply a rip-off of American designs, as this Ruixin is, and hurts our people and companies. Buy American, or from friendly democratic countries. Get the E.P. Apex, get quality kit made in America or in one of our allied countries.

Another question: according to Vadim @wootzblade the best blades' angle is 12 degrees no matter what steel. Do I need the angle to be adjustable or I can do with a simple set up for 12 grade since then it will be very easy to make DIY machine of few pieces of metal scrap but invest in a better stones?

I appreciate @wootzblade and he knows his stuff, and agree in general that more acute angles are a good thing. I've been tending to use more acute angles on a lot of my knives. Though not all...I have some larger knives that are designed to do heavier work. There are cases where you need other types of edge angles IMO, and you want your sharpener to support that. Personally I wouldn't get a sharpening setup that can only handle one angle, it's not flexible enough for me. A specific example is I have 2 ESEE Junglas blades, one is 8", the other 10". These are designed for chopping and hacking, they are thick blade stock with tough carbon steel. But if I use super acute edges, the edges tend to chip and to roll more easily when I'm chopping tough wood or vines. I've actually tried a more acute edge at 14 dps on one of those, it didn't work well so I went back to 20 dps. I'm just basing that on observation of what happened to the edges, I don't have any fancy electron scanning microscope to show the details in the steel's molecules and all that. But I can just tell you what worked and what didn't at my place, with my knives. For knives doing work like that, also some of my heavy duty machetes and survival-type knives, I'd tend to go with a more obtuse edge up around 18 to 22 d.p.s. So yeah, I like using acute edges when it makes sense, and 12 to 14 dps is what I'm using now on a lot of my folders and some kitchen knives. But I also see a case for more obtuse angles on some knives. It all depends on how you're using them. You want your sharpener to be able to support multiple angles, for sure.

The new EP Apex is great: I got 2 attachments that help with various blades. The small blade adapter lets you sharpen teeny tiny like blades, like some of the small Swiss Army Knife blades included in some of their multitools, or small kitchen paring knives, etc. The Slide Guide attachment makes it easier to sharpen all types of knives in general, it gives you 2 or even 3 points of contact to help stabilize a knife in the right position while you're running a stone over the edge. With the adapters, I did a little testing last night, I took the small blade adapter and a very narrow bladed kitchen paring knife. I was able to sharpen it down to 12 dps, no problem, and there was room to go lower, checked it at 10 dps and could've easily sharpened to that angle using the attachments.

I'm pretty happy with the EP so far, only sharpened 2 knives but it looks like it'll do everything I need it to. OP, in addition to getting EP Apex, I'd look at the stone packages for it that Gritomatic offers, I got his Venev diamond stones, but he also has some nice sets such as a Silicon Carbide set of 5 stones that would probably help keep your initial cost down (if that's a concern), and the SiC stones will sharpen everything in your collection. Good luck with your decision!

The angle only changes if the blade is curved. As most are. So, even with that system the angle changes at blade tip.Now I understand where the Ruixin copied their clamp design from... blatant rip-off! BTW, the channel that allows to maintain the stone perpendicular to the edge totally eliminates the problem of changing the angle as you move from the middle of the blade to the tip or ricasso area. Genius! The trade off is that the system is quite bulky but... other than that, I like it a lot. EZESharp you said? Of I go to find one!

Mikel

The Chinese CCP is a rotten communist dictatorship that rips off our tech, hurts our industries, abuses its own citizens

Glad you got the EdgePro. Not only is it's better built tool, but the supplied stones are superior to... the ones that come from that other location. If you'd bought the other one, you'd soon have to pony up for better stones.

- Joined

- Jan 4, 2016

- Messages

- 281

The mobile pivot unit is way worse than the fixed one for sharpening angle consistency. The fixed pivot unit creates a constant sharpening angle on a straight segment of the blade. When you move the mobile pivot unit, the angle will change unless the straight segment of the blade and the pivot unit rail are aligned to be parallel in 3D with extreme precision.BTW, the channel that allows to maintain the stone perpendicular to the edge totally eliminates the problem of changing the angle as you move from the middle of the blade to the tip or ricasso area. Genius!

BTW, the channel that allows to maintain the stone perpendicular to the edge totally eliminates the problem of changing the angle as you move from the middle of the blade to the tip or ricasso area. Genius!

Not clear what the EZESharp unit is doing that's different from any other similar system like Hapstone, EP, etc? It's holding the knife edge at a fixed angle perpendicular to the stone on the straight part of the blade, and as long as you use a flat consistent stroke and don't rock/tip your stone on the curved part, you should be able to keep a consistent edge regardless of which of system you use. Aren't all of these pretty similar in that basic aspect of how they maintain the angle, or am I missing something?

And the way they hold the stone introduces many inaccuracies when it is flipped from coarse to fine. So much work in the body but then they hacked the stone holder, what, did they run out of time?The mobile pivot unit is way worse than the fixed one for sharpening angle consistency. The fixed pivot unit creates a constant sharpening angle on a straight segment of the blade. When you move the mobile pivot unit, the angle will change unless the straight segment of the blade and the pivot unit rail are aligned to be parallel in 3D with extreme precision.

The mobile pivot unit is way worse than the fixed one for sharpening angle consistency. The fixed pivot unit creates a constant sharpening angle on a straight segment of the blade. When you move the mobile pivot unit, the angle will change unless the straight segment of the blade and the pivot unit rail are aligned to be parallel in 3D with extreme precision.

Yes and No. with a fixed pivoting point you will get always the same angle at any given point in the blade. But you will not get the same angle through the whole blade because the further you get from the clamp, the more acute is going to to be. With the sliding pivoting angle you need to be carefull keeping the stone perpendicular to the blade, but as long as you are carefull and the guide and the edge are paralell, you will get the same angle along the whole edge.

So it is a tradeoff.

Mikel

Think again. Pretend that fixed point is a chimney at a roof. And the blade is straight and along lower line of roof. Its the same angle where ever along the roof. If you raise or lower the low line of roof the angle changes. As if blade is curved instead of straight.

- Joined

- Sep 23, 2014

- Messages

- 1,287

HiNow I understand where the Ruixin copied their clamp design from... blatant rip-off!

Is it though?

Once patent expires (decade+ago), the design is public ... the prior art on these designs goes back a hundred years ...

ezesharp.com.au

https://patents.google.com/patent/AU638677B2/en

predates edge pro

https://patents.google.com/patent/US5185958

- Joined

- Sep 23, 2014

- Messages

- 1,287

Looks like you're all in agreement, on the straight part the angle doesn't change, but for the curve/tip the angle changes, gotta find sweet spot, unless you move the pivot..fixed point is a chimney at a roof...

edgepal demonstrates

10 meter long blade no angle change on the straight

- Joined

- Jan 4, 2016

- Messages

- 281

Every time you move the pivot unit horizontally, the sharpening angle changes. Not only curved parts but also straight parts - zones of the constant angle for fixed pivots. To keep the angle the same when you move the pivot horizontally, you also need to move the pivot vertically. Finding the sweet spot when clamping the knife takes time, but it should be done only once as part of the preparation of the sharpening session. With the mobile pivot unit, you will spend the same amount of time to align the blade in clamps to make it parallel to the horizontal rail. And everything you get is a pivot-independent constant angle for one straight segment (like your nice pictures show). For all other parts of the blade, it's better to secure the pivot at one point and forget about mobility. Because otherwise, it's a nightmare.Looks like you're all in agreement, on the straight part the angle doesn't change, but for the curve/tip the angle changes, gotta find sweet spot, unless you move the pivot

Let me get straight to the points.

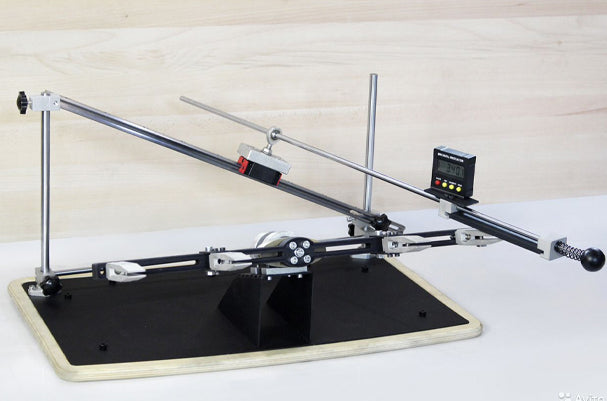

1) Guided sharpeners with a mobile pivot on the horizontal rail are not something new. When designed correctly, they can do things beyond the capabilities of ordinary systems. Sharpeners with a mobile pivot constitute the group called "Sharpeners with variable sharpening angle". What an irony - the technology created to change sharpening angle are recognized by many as completely opposite.

2) Be very skeptical when someone tells you about a sharpener, a technology, or a trick where the angle doesn't change. Sharpeners with constant angles don't exist.

3) What "designed correctly" means? In my opinion, there are two main requirements: A) the user should have an option to immobilize the pivot unit; free-moving pivot is not acceptable. B) the user positions the rail in two dimensions; usual implementation - 2 vertical rods with independent rail carriers.

4) Sharpeners with variable sharpening angle are "hard to learn/hard to master". But it could be rewarding. Probably it's a better tool than usual sharpeners to control bevel width and keep it constant.

5) Usual sharpeners with the fixed pivot unit are unbeatable in angle consistency. The angle can change across the blade, but it will not change in time.

6) Constant angle sharpening is a holy crusade for inventors and engineers. Some ideas get picked and become milestones. Some don't, become nothing. I got bad news for EZESharp users... She starred in one of the ones that became nothing.

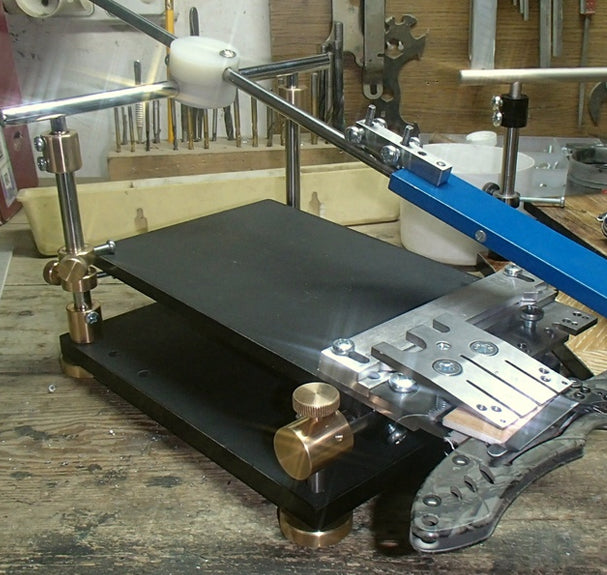

Remarkable sharpeners with variable sharpening angle

KakBritva EdgeCompactComfort

AST-4U

A.V.X.1960 (inventor's nick)

Kontur MK500

Longsword Sharpener (link)

We

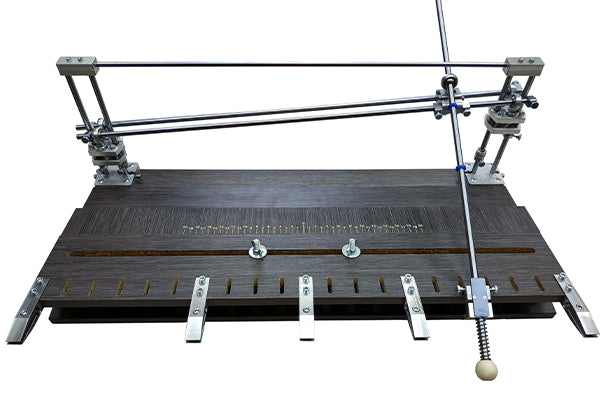

Well, in terms of metal, complexity and machinery orgies yes.In the battle edge-pro-apex-4-vs-ruixin the winner is Extreme TI:

- Status

- Not open for further replies.