-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edge Pro Apex 4 Vs Ruixin

- Thread starter Barmaley

- Start date

- Status

- Not open for further replies.

Every time you move the pivot unit horizontally, the sharpening angle changes. Not only curved parts but also straight parts - zones of the constant angle for fixed pivots. To keep the angle the same when you move the pivot horizontally, you also need to move the pivot vertically. Finding the sweet spot when clamping the knife takes time, but it should be done only once as part of the preparation of the sharpening session. With the mobile pivot unit, you will spend the same amount of time to align the blade in clamps to make it parallel to the horizontal rail. And everything you get is a pivot-independent constant angle for one straight segment (like your nice pictures show). For all other parts of the blade, it's better to secure the pivot at one point and forget about mobility. Because otherwise, it's a nightmare.

Let me get straight to the points.

1) Guided sharpeners with a mobile pivot on the horizontal rail are not something new. When designed correctly, they can do things beyond the capabilities of ordinary systems. Sharpeners with a mobile pivot constitute the group called "Sharpeners with variable sharpening angle". What an irony - the technology created to change sharpening angle are recognized by many as completely opposite.

2) Be very skeptical when someone tells you about a sharpener, a technology, or a trick where the angle doesn't change. Sharpeners with constant angles don't exist.

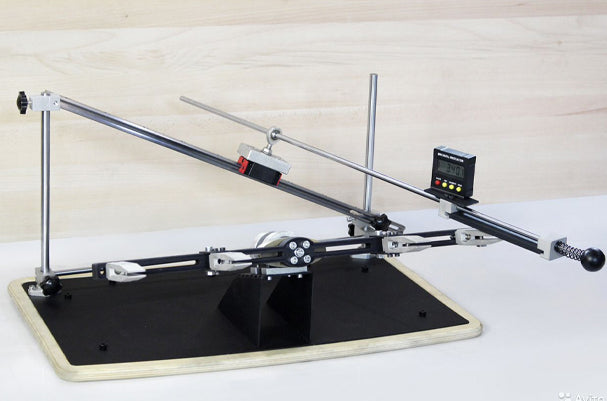

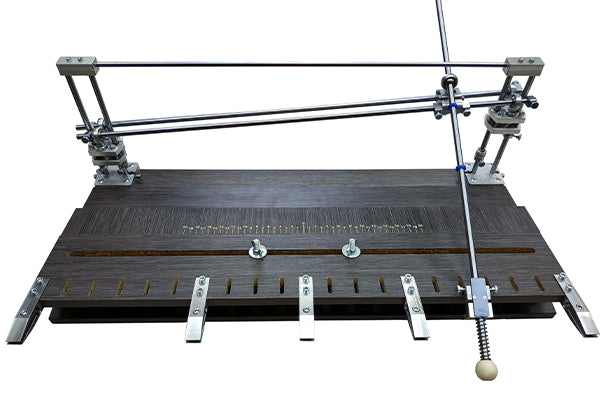

3) What "designed correctly" means? In my opinion, there are two main requirements: A) the user should have an option to immobilize the pivot unit; free-moving pivot is not acceptable. B) the user positions the rail in two dimensions; usual implementation - 2 vertical rods with independent rail carriers.

4) Sharpeners with variable sharpening angle are "hard to learn/hard to master". But it could be rewarding. Probably it's a better tool than usual sharpeners to control bevel width and keep it constant.

5) Usual sharpeners with the fixed pivot unit are unbeatable in angle consistency. The angle can change across the blade, but it will not change in time.

6) Constant angle sharpening is a holy crusade for inventors and engineers. Some ideas get picked and become milestones. Some don't, become nothing. I got bad news for EZESharp users... She starred in one of the ones that became nothing.

Remarkable sharpeners with variable sharpening angle

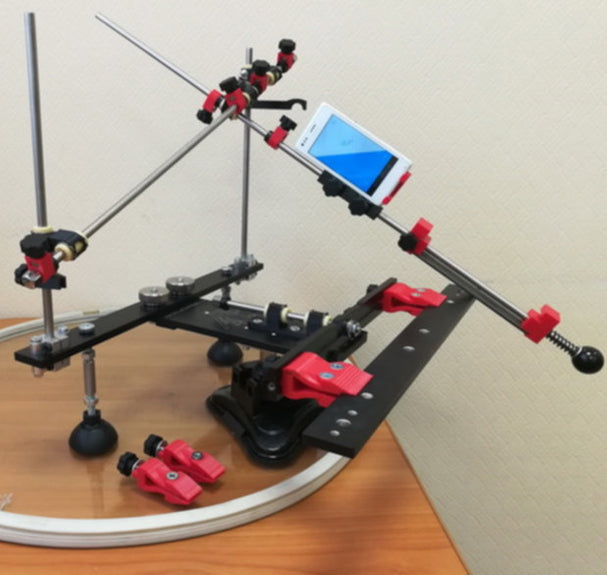

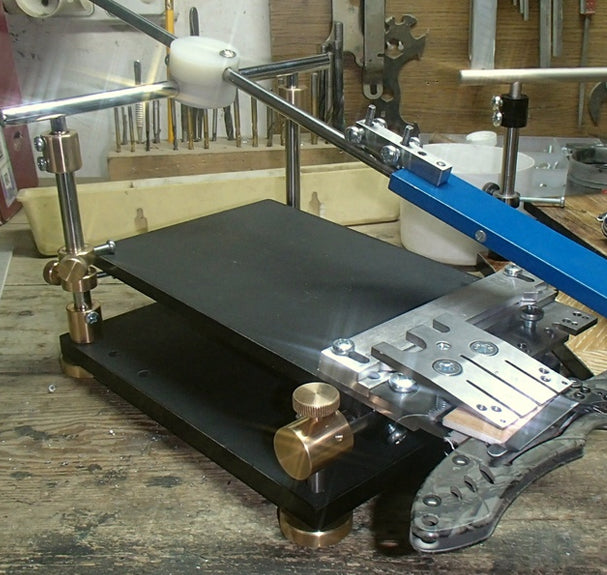

KakBritva EdgeCompactComfort

AST-4U

A.V.X.1960 (inventor's nick)

Kontur MK500

Longsword Sharpener (link)

OMG!

My reaction to all this:

* The guys building these sharpeners are smart, and

* OMG--the complexity of it all. No wonder a lot of us still prefer freehanding--even *if* our edge is not perfectly, beautifully consistent throughout. Just wanna a pick up a blade and sharpen.

- Joined

- Oct 11, 2014

- Messages

- 1,040

OP, My preconceptions are that clamps requiring Allen wrenches might get tedious. Many DIY systems use shelves. Wickededge’s WE 130 and up has a wrench free clamp. Hapstone system has both knife clamp options and shelf options. I thought I saw a similar option for EdgePro somewhere? The EdgePro system is loved by many, magnets are always available, and Diemaker's new slide guide are now available. I standardized on KME for beginner sharpening training and cost. I have sharpened 21 knives on a Sharpmaker Ken Onion Edition in 2 and a half evening sessions, and now understand why almost 6500 big river reviews are 95 percent 4 and 5 stars, and my son in law loves his WSKO.

Sliders-

Several years ago, doing homework on the enormously over designed EZESharp, I discovered they are used by meat cutting operations, so if it works for them, that is good enough for me. Thomas, the EdgePal inventor builder was solving a problem; he uses it, so again good enough. Grievous human rights violations aside, which I cannot (annually reported by the US State department), China makes clones for less greenbacks, but I expect to will my tools to the kids, and reviews suggest some models need tinkering, eg. a KME clone model had clamps machined incorrectly and needing repair.

Interesting Konstantin et al...

I just got a laser that projects leveled XY lines, with origin, on surfaces. As experienced on our KME, I expect a 2nd pointer laser in a fixed position and rotated side to side will create a line diverging, converging, or tracking, along the horizontal X axis described on surface by the projected laser coordinate system. The laser beam’s mimicking a KME stone holder's horizontal movement, dependent on plane, straight, and curved sections of an edge (Konstantin's “zones of the constant angle for fixed pivots.”- am I understanding "zones" correctly?).

If the stone holder slide keeps the edge perpendicular to the contact patch of the stone, I expect the divergence, convergence, or tracking to be close to a fixed pivot point stone holder.

Sliders-

Several years ago, doing homework on the enormously over designed EZESharp, I discovered they are used by meat cutting operations, so if it works for them, that is good enough for me. Thomas, the EdgePal inventor builder was solving a problem; he uses it, so again good enough. Grievous human rights violations aside, which I cannot (annually reported by the US State department), China makes clones for less greenbacks, but I expect to will my tools to the kids, and reviews suggest some models need tinkering, eg. a KME clone model had clamps machined incorrectly and needing repair.

Interesting Konstantin et al...

andyou also need to move the pivot vertically

It seems like the devil is in the details here. Practically speaking, using a simple slide for the stone holder, with the expectation that the off hand will control perpendicular orientation to grinding of straight edge works geometrically. For other then straight edges, think Karambit / Kukri / Bowie / Machete, etc, I need a significant variance quantified before introducing complexity of variable-x axis and vertical-y axis adjustments along the slides plane.10 meter long blade no angle change on the straight

I just got a laser that projects leveled XY lines, with origin, on surfaces. As experienced on our KME, I expect a 2nd pointer laser in a fixed position and rotated side to side will create a line diverging, converging, or tracking, along the horizontal X axis described on surface by the projected laser coordinate system. The laser beam’s mimicking a KME stone holder's horizontal movement, dependent on plane, straight, and curved sections of an edge (Konstantin's “zones of the constant angle for fixed pivots.”- am I understanding "zones" correctly?).

If the stone holder slide keeps the edge perpendicular to the contact patch of the stone, I expect the divergence, convergence, or tracking to be close to a fixed pivot point stone holder.

- Joined

- Oct 11, 2014

- Messages

- 1,040

- Joined

- Jan 4, 2016

- Messages

- 281

Why? What magic do you see in "keeping the edge perpendicular to the contact patch of the stone" (⟂rule to shortcut)?If the stone holder slide keeps the edge perpendicular to the contact patch of the stone, I expect the divergence, convergence, or tracking to be close to a fixed pivot point stone holder.

When you sharpen on Edge Pro Apex in a classic way (no slide guide, no magnets), you always have ⟂rule. And you get an "almost constant" angle on Karambit.

When you sharpen on Edge Pro Apex in a modern way (slide guide + magnets), ⟂rule is not fulfilled. And the angle change over Karambit will be substantial.

If a sharpening system utilizes a mobile pivot unit because ⟂rule is dogma, it's a cargo cult.

⟂rule in classic Edge Pro Apex is just a coincidence. Place the vertical rod 5" to the right.. and nothing dramatic will happen - Apex will not lose the angle preserving.

Sharpening customs chasing "constant angle" are designed in Edge Pro paradigm of mobile blade. It could be a very sophisticated unit with clamps or not clamps, but they provide the degree of freedom for knives.

Examples

1) Mobile rotating clamp system in GRID-VIVA:

2) Mobile magnetic table in Bogdan Manko's Krivolapka (time 9:41)

Why? What magic do you see in "keeping the edge perpendicular to the contact patch of the stone" (⟂rule to shortcut)?

When you sharpen on Edge Pro Apex in a classic way (no slide guide, no magnets), you always have ⟂rule. And you get an "almost constant" angle on Karambit.

When you sharpen on Edge Pro Apex in a modern way (slide guide + magnets), ⟂rule is not fulfilled. And the angle change over Karambit will be substantial.

If a sharpening system utilizes a mobile pivot unit because ⟂rule is dogma, it's a cargo cult.

⟂rule in classic Edge Pro Apex is just a coincidence. Place the vertical rod 5" to the right.. and nothing dramatic will happen - Apex will not lose the angle preserving.

Sharpening customs chasing "constant angle" are designed in Edge Pro paradigm of mobile blade. It could be a very sophisticated unit with clamps or not clamps, but they provide the degree of freedom for knives.

Examples

Hey Konstantin, what do you mean by "⟂rule"? And the difference between "classic" and "modern" sharpening with regard to ⟂rule? Sorry, I haven't had enough coffee yet.

- Joined

- Oct 2, 1998

- Messages

- 48,191

Hey Konstantin, what do you mean by "⟂rule"? And the difference between "classic" and "modern" sharpening with regard to ⟂rule? Sorry, I haven't had enough coffee yet.But since I just started using EP Apex, I'm interested in your point about the Edge Pro differences.

I'm thinking, (always a dangerous thing), that it is supposed to represent the gadget's arm holding the abrasive perpendicular to the knife edge, (or end of the sharpening table), but that is a supposition on my part...

...So that when you sharpened as the Edge Pro was originally intended, you slid the blade along the table, generally keeping the edge parallel to the end of the table, and perpendicular to the back and forth motion of the abrasive.

With the magnet and Slide Guide, the blade stays fixed to the table, (generally speaking), and the abrasive sharpens along the length of the blade from angles other than perpendicular to the edge.

I hope that makes sense.

^It does, if that is Konstantin's point, than that makes sense and I can see that already from my own usage. At first I didn't get why a couple people in this form in various posts/threads were saying stuff about the EP like 'it changes the angle when you sharpen the belly/curve/tip.' My thought was no it really doesn't, but that's because I was using it the way the Ben demo's it on the EP sight, I actually move the blade with my support hand like they recommend.

But now that I have the magnet and slide guide, yes I get that distinction. If you sort of 'lock' the knife in place on the table, and DON'T move it all, then you're using it just like a fixed clamp system. So that you're swinging the blade out and following the curve in the belly, then yeah, that's definitely changing the angle at that point on the blade. I tried that for myself last evening, I put a cheap crap huge hunting knife 1095 steel with a deep belly on there using the magnet and "slide guide." It was handy having it held in place in a way that you can sharpen the whole blade with one stroke. But...absolutely the angle on the curve changes a little when you keep the knife in that fixed position. It wouldn't be so much that the edge is unusable, but man when you sharpen it later, you'll really mangle your existing edge because if you don't position that knife EXACTLY on the table/magnet/slide-guide the way you did the first sharpening, you'll practically have to reprofile your whole edge.

But the 'classic' EP approach--aka "moving the knife to keep edge perpendicular" is exactly why I like the EP. It gives you a lot of the advantages of freehanding, but with the convenience of the stone held at a fixed angle. There are still a ton of things you can screw up though with the EP, I may have discovered a few of them already.

But now that I have the magnet and slide guide, yes I get that distinction. If you sort of 'lock' the knife in place on the table, and DON'T move it all, then you're using it just like a fixed clamp system. So that you're swinging the blade out and following the curve in the belly, then yeah, that's definitely changing the angle at that point on the blade. I tried that for myself last evening, I put a cheap crap huge hunting knife 1095 steel with a deep belly on there using the magnet and "slide guide." It was handy having it held in place in a way that you can sharpen the whole blade with one stroke. But...absolutely the angle on the curve changes a little when you keep the knife in that fixed position. It wouldn't be so much that the edge is unusable, but man when you sharpen it later, you'll really mangle your existing edge because if you don't position that knife EXACTLY on the table/magnet/slide-guide the way you did the first sharpening, you'll practically have to reprofile your whole edge.

But the 'classic' EP approach--aka "moving the knife to keep edge perpendicular" is exactly why I like the EP. It gives you a lot of the advantages of freehanding, but with the convenience of the stone held at a fixed angle. There are still a ton of things you can screw up though with the EP, I may have discovered a few of them already.

- Joined

- Oct 2, 1998

- Messages

- 48,191

Even when using the magnet and slide guide, I think it's a good idea to move and remount the blade, (for the second or two it takes to accomplish), when the blade is either a couple of inches longer than the sharpening table, or has a characteristic which would call for handling a portion of the edge with particular attention and consideration.

Thank you very much gentlemen for your advice. I got a ton of valuable information here; special thanks to

scottc3

for the links!

scottc3

for the links!

I am on my 3 generation of sharpening apparatus. As everybody needs are different I had to consider that I am only concern about sharpening of my kitchen knives and I have no more than a dozen of them. My goals were: A) the most consisted result in terms of angle between today and future sharpenings B) constant 12 DPS angle for all blades C) simplest to build and simplest to operate device. D) ability to use stones beyond Apex type stones including 8" long ones. This brings me to my current plan: Fixed magnet based knife holder at 12 degree. Preset number of blade positioning pins for each knife. Esesharp style rod holder. rod holder should have 0.5 degree step adjustment for each next bevel with -0.5 degree for the main bevel. I think it will take me a couple of weeks to finish it since I still have some conflicting ideas which parts will fit the most (I have multiple options of available parts). I am pretty sure that biggest majority of the members here will not find this design useful since as I understand 90% are concern about tactical knives but not kitchen knives.

I am on my 3 generation of sharpening apparatus. As everybody needs are different I had to consider that I am only concern about sharpening of my kitchen knives and I have no more than a dozen of them. My goals were: A) the most consisted result in terms of angle between today and future sharpenings B) constant 12 DPS angle for all blades C) simplest to build and simplest to operate device. D) ability to use stones beyond Apex type stones including 8" long ones. This brings me to my current plan: Fixed magnet based knife holder at 12 degree. Preset number of blade positioning pins for each knife. Esesharp style rod holder. rod holder should have 0.5 degree step adjustment for each next bevel with -0.5 degree for the main bevel. I think it will take me a couple of weeks to finish it since I still have some conflicting ideas which parts will fit the most (I have multiple options of available parts). I am pretty sure that biggest majority of the members here will not find this design useful since as I understand 90% are concern about tactical knives but not kitchen knives.

- Joined

- Jan 4, 2016

- Messages

- 281

^It does, if that is Konstantin's point, than that makes sense and I can see that already from my own usage. At first I didn't get why a couple people in this form in various posts/threads were saying stuff about the EP like 'it changes the angle when you sharpen the belly/curve/tip.' My thought was no it really doesn't, but that's because I was using it the way the Ben demo's it on the EP sight, I actually move the blade with my support hand like they recommend.

Yes and no. You are absolutely correct regarding your own experience with EP. When someone says "the angle changes throughout the blade", with 99% probability the person does not know what the term "sharpening angle" means and how to measure it. They think they know, but they don't. The intuition and the experiment together are powerful tools that "prove" that angle changes through a straight blade. Turn on the angle cube and here you go. It's difficult to prove it does not work like that. It's difficult for many reasons:

1) "Oh, these funny theorists are so armchair experts".

2) because people don't want to hear everything they know is wrong.

3) there are many ways to measure sharpening angle in any given point incorrectly, and only one correct.

4) proofs coming from theoretic calculations, CAD 3D modeling, and goniometry analysis of edge are difficult to accept.

That's how to angle measurement usually looks like.

It is the sharpening angle (if I decide to sharpen it). That's how it's correctly measured by you, me, and many others to set up the angle for sharpening sessions.

Whenever you see someone is measuring a sharpening angle like that - run!

It's the most common "proof" of "the angle changes throughout the blade". But the reading is not sharpening angle. The sharpening angle is the angle between two planes. But angle cubes don't work with planes! Angle gauges work with lines. We can measure sharpening angle with angle gauge only if the lines are perpendicular to the cutting edge.

By rotating the angle gauge, we can align to be perpendicular to the cutting edge. Now the reading is the sharpening angle (if the gauge supports tilting).

Only when all parties understand how the sharpening angle is measured, debates about it have sense.

P.S. Should I comment on why the sharpening angle changes over a straight line on my photos?

- Joined

- Oct 2, 1998

- Messages

- 48,191

Only when all parties understand how the sharpening angle is measured, debates about it have sense.

P.S. Should I comment on why the sharpening angle changes over a straight line on my photos?

Of course, you should, Konstantin. This way we will all be working on the same page and you can contribute to the knowledge base here by doing so.

Thanks for sharing your images. (I was playing with doing the same thing yesterday while I had a few spare moments...but without images.)

If the stone holder rod is perpendicular to the upright the angle doesn't change. The further from perpendicular the more the angle will change as the stone is moved further from the sharpeners centerline. With the Apex the rod is perpendicular at 21 degrees, if memory serves.

- Joined

- Oct 2, 1998

- Messages

- 48,191

If the stone holder rod is perpendicular to the upright the angle doesn't change. The further from perpendicular the more the angle will change as the stone is moved further from the sharpeners centerline. With the Apex the rod is perpendicular at 21 degrees, if memory serves.

Yes...

The Apex base, (at least mine), has a 29.5* angle. With the arm set up on the yellow dot, (21*), I rested it on the edge of a Mora knife using your slide guide and magnet to hold it in place. (I was using with one of the diamond hones which I bought from Ben several years back.)

The Wixey digital angle finder read 8.5*. Subtract from 29.5* = 21* Right on spec.

I should add that using an angle gage to test this the sharpener needs to be on a dead level surface, the body plate of the sharpener needs to be parallel with that surface along its width, and the "knife" needs to be parallel with the face of the body and reference surface. Getting all of this accurate, except for the reference surface, is very difficult even for me unless I use one of my cnc mills to indicate it all in.

- Joined

- Oct 2, 1998

- Messages

- 48,191

I should add that using an angle gage to test this the sharpener needs to be on a dead level surface, the body plate of the sharpener needs to be parallel with that surface along its width, and the "knife" needs to be parallel with the face of the body and reference surface. Getting all of this accurate, except for the reference surface, is very difficult even for me unless I use one of my cnc mills to indicate it all in.

I have mine mounted permanently on the counter top alongside my shop sink. The rest I measured as carefully as my eyes and hands could manage.

The further from perpendicular the more the angle will change as the stone is moved further from the sharpeners centerline.

Can you expand on that a bit? Not quite following...maybe a visual.

Sorry but no time for photos, I'm too busy pulling my hair out making a new website. For the Apex the stone holder rod is perpendicular to the vertical rod that attaches it to the sharpener base/back when set to 21 degrees so that it and the vertical rod form the right angle legs of an isosceles triangle. When this is the case there is no angle change as long as the blade edge being sharpened is in the same plane as the stone holder. That plane is 90 degrees from the vertical rods centerline where the stone holder centerline intersects it. If you change the angle then the stone holder rod and vertical rod are no longer 90 degrees from each other and the angle between the blade edge and stone holder will change as you move it from the sharpener center. The farther from 21 degrees you sharpen the more angle change you will see while sharpening.Can you expand on that a bit? Not quite following...maybe a visual.

If the sharpener maintained that right angle between the vertical rod and stone holder and changed sharpening angles by rotating the blade table with its center of rotation on the stone holders plane, which is impossible, you would have no angle change as you sharpened long knives with dead straight blades.

Sorry but no time for photos, I'm too busy pulling my hair out making a new website. For the Apex the stone holder rod is perpendicular to the vertical rod that attaches it to the sharpener base/back when set to 21 degrees so that it and the vertical rod form the right angle legs of an isosceles triangle. When this is the case there is no angle change as long as the blade edge being sharpened is in the same plane as the stone holder. That plane is 90 degrees from the vertical rods centerline where the stone holder centerline intersects it. If you change the angle then the stone holder rod and vertical rod are no longer 90 degrees from each other and the angle between the blade edge and stone holder will change as you move it from the sharpener center. The farther from 21 degrees you sharpen the more angle change you will see while sharpening.

Not quite seeing that, seems different from Konstantin's point, particularly the highlighted part not sure I'm tracking with that.

- Joined

- Oct 2, 1998

- Messages

- 48,191

When this is the case there is no angle change as long as the blade edge being sharpened is in the same plane as the stone holder. That plane is 90 degrees from the vertical rods centerline where the stone holder centerline intersects it.

David, assume you are in line with the stone holder, directly perpendicular to the vertical rod. Are you saying that you can go out 45 degrees left or right from the center of the sharpening table and have no angle change? (Assuming a straight edge which lines up with the end of the table.)

- Status

- Not open for further replies.