- Joined

- Jun 29, 2020

- Messages

- 33

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

Larrin what's the deal with the toughness rating on m390/20cv/204p? In older articles it was up about 10, but now it's down around 5. Do you have an article about the update in toughness results? I dug around but couldn't find anything.

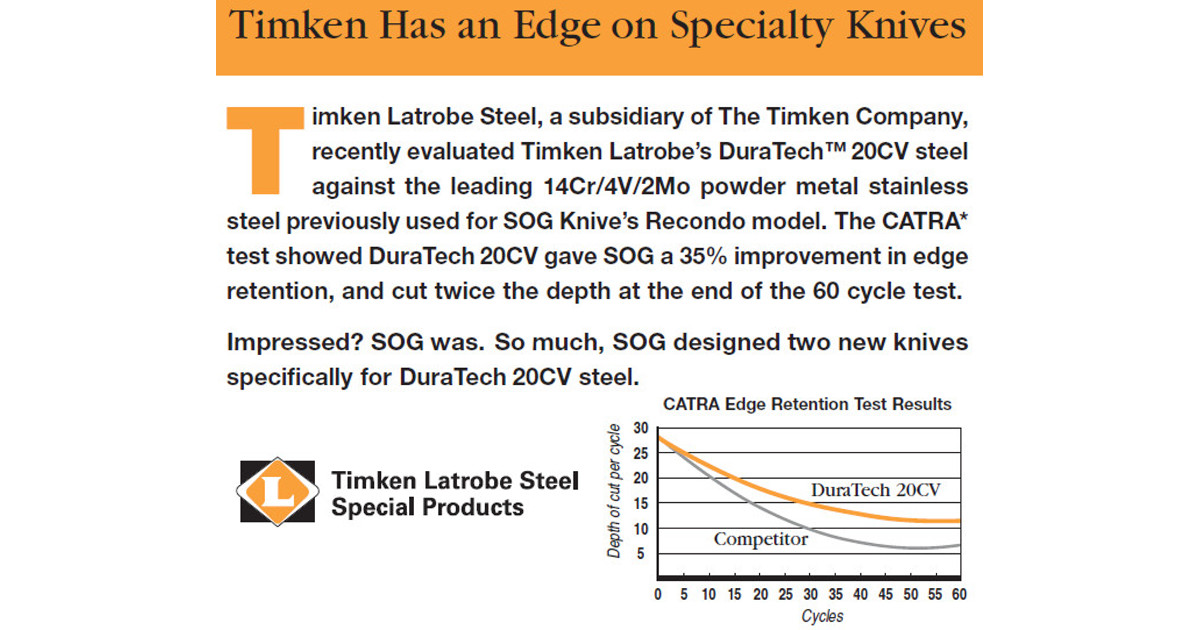

If they can sharpen it better it starts further from dull so it cuts longer.My point is that with many people using CATRA to judge edge retention, LC200N does well to keep up with some higher end steels in rope cutting without having to rely on hardness or abrasion resistance.

Thanks for all your hard work! I bought a copy of your book, but haven't started reading it yet. Being more than 400 pages it will be the thickest book i will read since college days, not counting my current book, the Bible.Recently I was able to acquire a used CATRA machine, so I heat treated just about every knife steel I had, made 57 knives with the help of knifemaker Shawn Houston, and tested them all to see which cut the longest. For a few of the steels I did multiple heat treatments to look at a couple variables and to see the effect of hardness. I also compared edge retention and toughness to see which steels have the best balance of properties. https://knifesteelnerds.com/2020/05/01/testing-the-edge-retention-of-48-knife-steels/

Larrin, excellent testing, also ordered your book, as I am sure it is a good read.

Did I read correctly that the blade profile was 3dps and the edge was 15dps? Also how thick were the samples, 1/8"? Tried reading through everything this morning.

Was the cryo done as part of the HT continuously and not after the HT was done? It appears that's the case when I read it, but verifying.

www.instagram.com

www.instagram.com

Login • Instagram

Welcome back to Instagram. Sign in to check out what your friends, family & interests have been capturing & sharing around the world.www.instagram.com

Here's a video of how I sharpened them.

Yes 3 dps and yes 15 dps. The majority were 1/8” though a few were thinner. The constant primary and secondary grind was selected so that the stock thickness differences are irrelevant.Larrin, excellent testing, also ordered your book, as I am sure it is a good read.

Did I read correctly that the blade profile was 3dps and the edge was 15dps? Also how thick were the samples, 1/8"? Tried reading through everything this morning.

Was the cryo done as part of the HT continuously and not after the HT was done? It appears that's the case when I read it, but verifying.

If that were the case then many of the other low carbide steels would also perform better than expected.If they can sharpen it better it starts further from dull so it cuts longer.

It's not just low Carbide volume, there are other variables, that's why I said "whatever can be sharpened better" not specifically low carbide volume etc.If that were the case then many of the other low carbide steels would also perform better than expected.

Comparing S30V to LC200N paired up by sharpener used, edge angle, and final finishing.

Spyderco heat treat S30V at 59-60rc and LC200N at 57-58

Benchmade S30V is at 57.7

These numbers seem fairly consistent but if there's something else I'm missing please let me know because they don't seem wrong to me.

The rope used is twisted sisal twine which is barely abrasive. During cutting most of the fibers will naturally be at an off angle relative to the edge no matter how you cut it and cause repeated lateral stresses.

LC200N having a much higher toughness would definitely help out to resist fatigue here.

Yes cryo was done directly after the quench. I’ve never performed cryo in any other way, for the reasons given in my cryo articles.

Heating above critical means you are forming a new set of austenite grains and then cooling to form pearlite. It is the rapid formation of new grains which helps to refine grain. If heating below transformation you are not forming new grains. You may be affecting the carbide structure which can have an indirect effect on the final heat treated grain size but it’s not the same thing.Larrin - you mentioned earlier in this thread that refining grain by going above and below critical in cycles works. Do you know if anything useful happens in plain steels if steel is heated (quick, in a forge) subcritical (red, but never nonmagnetic) and then quenched, and then followed by a typical higher temp heat and quench? Will that refine grain size or is it likely doing nothing?

(this question has to do with trying to cheat and improve toughness without propagating iron carbides that don't later get dissolved - 26c3 in this case).

Heating above critical means you are forming a new set of austenite grains and then cooling to form pearlite. It is the rapid formation of new grains which helps to refine grain. If heating below transformation you are not forming new grains. You may be affecting the carbide structure which can have an indirect effect on the final heat treated grain size but it’s not the same thing.