hugofeynman

Gold Member

- Joined

- Jan 18, 2011

- Messages

- 1,001

No.

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

As structural engineer what do you think about this kind of blade/distal taper from tip to butt and tapered from spine to bottom side of blade/ compared with same blade but with normal / lengthwise/ tapered tang ? Which one is stronger ?I am a structural engineer so I know a lot about strength of materials.

It used to be standard for a fine custom knife to have a tapered tang which was their way of keeping full strength but reducing weight and improving balance. T

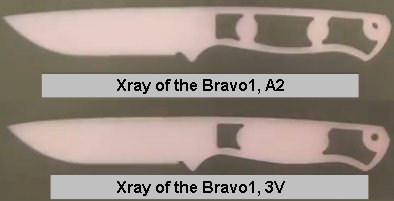

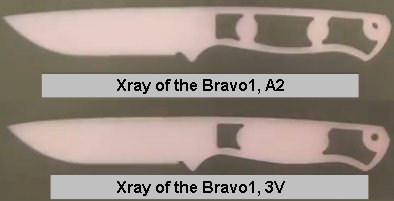

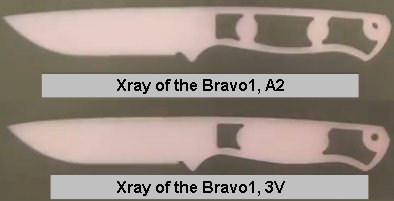

I would like to see someone to bend/break that tang if you put carbon fiber or micarta 6-7mm thick scale mounted with corby bolts and glued with epoxyAh I see. He didn't word it like that. I was inquiring about the Bravo 1 because it has a very skeletonized tang. Do you think the handle adds a lot of strength? It baffles me that two small pieces of thin metal like on the Bravo tang could have any strength at all. But.. if the handle has a lot of strength and it extends up past the thinnest part a significant amount then maybe it adds a lot of strength?

I once in fact used a sledge hammer to baton a SOG fixed blade and had no problems what's so ever with the knife. I don't recommend that practice and have not done it since. I was playing around with a knife I really didn't care if I broke or not.

This is OP's handle in question maybe ? https://www.bladeforums.com/threads...ang-is-so-skeletonized.1607822/#post-18367120

What about the difference between hardness and toughness? Since the steel is hardened to an extent, would the flexibility matter? I'm really just curious, not looking to argue.Wow, there is a lot of misinformation floating around on this subject (dealer guy is F.O.S.). When you hear that an I-beam is stronger than a solid square steel beam with the same outside dimensions, THAT is false. If you're talking cross-sectional area, then the I-beam is far stronger. So basically, a knife handle with identical material, exterior dimensions and thickness can never be stronger when skeletonized than when it's solid. However, most solid knife handle are so overly strong that skeletonizing doesn't really make enough of a difference to matter. Steel is a wonderfully strong material.

This is OP's handle in question maybe ? https://www.bladeforums.com/threads...ang-is-so-skeletonized.1607822/#post-18367120

A good number of mid-tech and custom builders will still use the tapered tang to improve balance through reducing grip weight. It is also considered by many, including myslef, to aid in the beauty of the finished product.It used to be standard for a fine custom knife to have a tapered tang which was their way of keeping full strength but reducing weight and improving balance. This would probably be expensive for a production knife company to do so they just order the blanks with holes cut in the tang.

I believe that a full tang is just that...one that extends to the butt of the grip...regardless of drilled or milled lightening holes.When someone says "full tang" before I was just under the impression that it meant full tang. When I saw that image it made me question that assumption. How much material needs to be removed and in what configuration until it becomes a partial tang at best?

Yes it was originally but I think it applies to any knife. When someone says "full tang" before I was just under the impression that it meant full tang. When I saw that image it made me question that assumption. How much material needs to be removed and in what configuration until it becomes a partial tang at best? I think it's a valid question.

What about the difference between hardness and toughness? Since the steel is hardened to an extent, would the flexibility matter? I'm really just curious, not looking to argue.