BD_01

Basic Member

- Joined

- Jun 9, 2016

- Messages

- 3,987

Bravo to MD for addressing the clip.

Also, thanks to everyone on BF and the MD boards for ranting about the issue and keeping the pressure on.

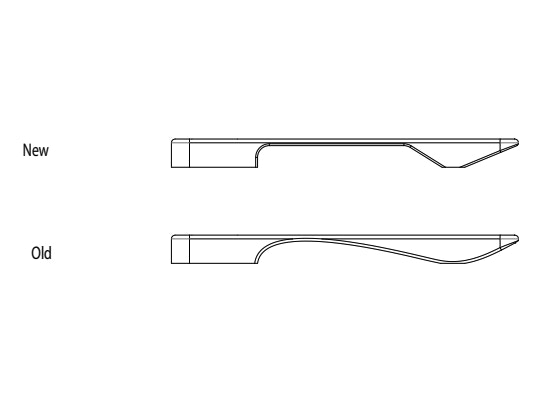

While I would much rather see a stamped Ti or steel clip, yes, the main issue is one of flexibility. Milled Ti clips are tough to get right. The new one definately looks like an improvement.

BTW, Pop’s Custom now has stamped Ti deep cary clips for the Falcon. I ordered one yesterday. Honestly it was a bit more than I wanted to pay, giving the cost of the knife. The Crux is definately worth it (for me, anyway).

Also, thanks to everyone on BF and the MD boards for ranting about the issue and keeping the pressure on.

While I would much rather see a stamped Ti or steel clip, yes, the main issue is one of flexibility. Milled Ti clips are tough to get right. The new one definately looks like an improvement.

BTW, Pop’s Custom now has stamped Ti deep cary clips for the Falcon. I ordered one yesterday. Honestly it was a bit more than I wanted to pay, giving the cost of the knife. The Crux is definately worth it (for me, anyway).

). Design/redesign aside, the replacement offer is a good move.

). Design/redesign aside, the replacement offer is a good move.