- Joined

- Jun 10, 2015

- Messages

- 842

Any reason why the new model ZTs (204/220/456) lack the sleeved/sandwich construction (screwed into standoffs from both frame and lockside)? Construction/Build Quilty has always been a trait of ZT.

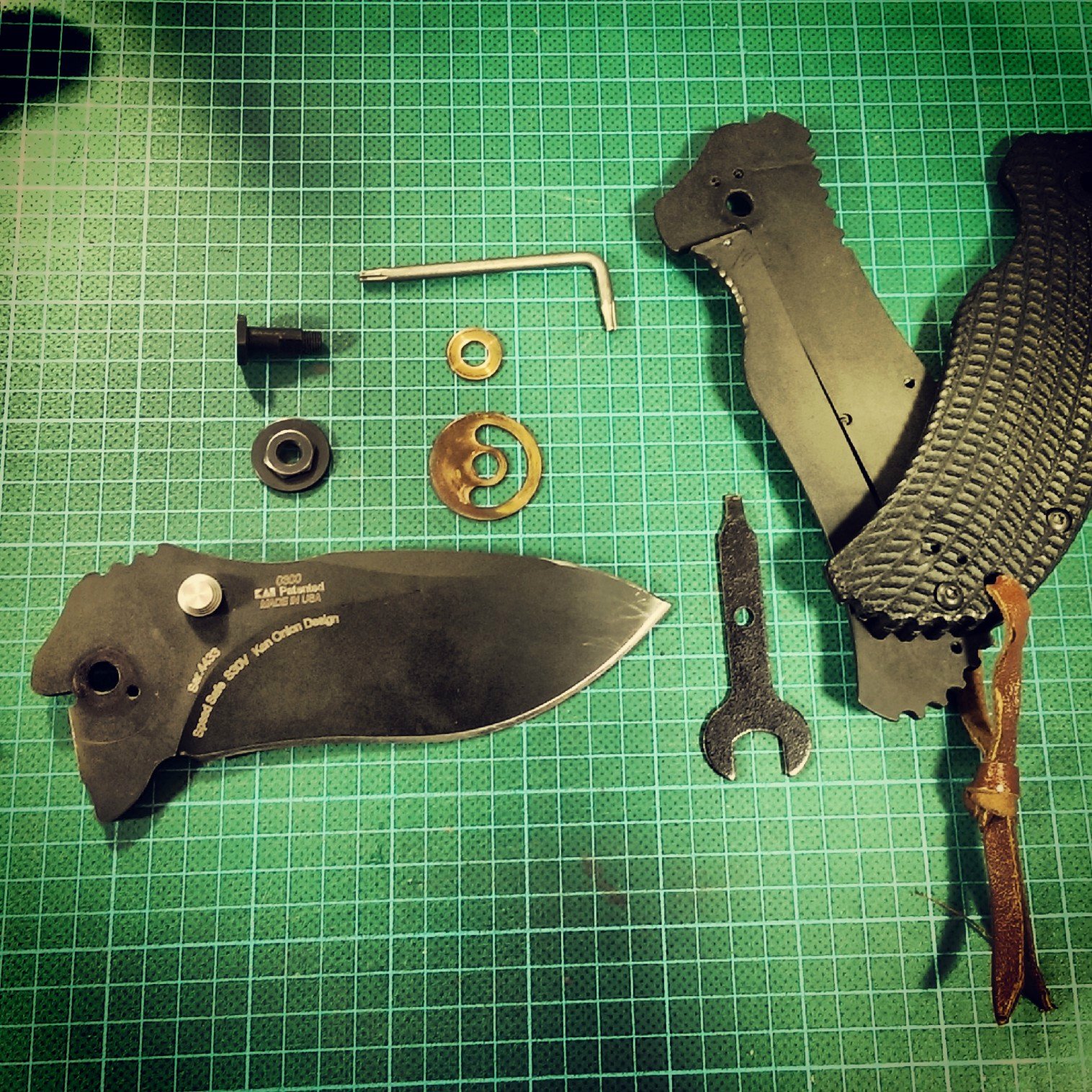

Construction of newer model (note: screws going directly into the titanium frame)

Construction of newer model (note: screws going directly into the titanium frame)

Last edited: