I really appreciate all the time and effort you've put in to replying to my questions and ... I'll give that a try next (0.5u)

You're welcome.

I've tried the diamond stones I ordered, which seemed to work pretty well (240, 400, 800, 1000)

And followed it up with (the cheapo aluminum oxide I think) afterwards in 800, 1500, 2000, 3000.

Which "cheapo" stones are these? I once got some no-name stones off ebay and they were terrible, and the grades didn't seem to mean anything like they just printed numbers randomly. Don't drive yourself crazy with those if they don't seem to work right.

With burr reduction methods and stropping on plain paper (no compound) you should be able to shave arm hair from a stone in the F320 or JIS #400 range. There's no lower (coarser) limit to that really, and I bet there are people on this forum who can shave arm hair directly off a #20 dressing stone as a party trick. However if you aren't getting an arm hair shaving edge off a #400 grit stone after stropping the edge is not being fully finished. Either you haven't fully formed the apex or you haven't deburred it satisfactorily. This can still be a "working edge" depending on what that work is but it's not showing the full potential yet.

Arm hair shaving, especially if it is "scrape" shaving, really isn't a particularly high level of performance and it shouldn't take special equipment to get there. Hanging hair tests (HHT), hair whittling, tree-topping, and comfortable face shaving are much,

much harder tests to pass. To this day I have never gotten an edge on a pocket knife that I could comfortably shave my whole face with, using the same abrasives I did on a straight razor. Kudos to those who can. Incidentally I gave up using a straight because I only had one and sometimes my honing gave me a crappy edge and razor burn despite the previous honing giving a comfortable shave. Looking at Todd Simpson's tests I probably had a big foil burr I didn't know how to address, but I am too lazy now to go back to it as I like to be able to drop in a fresh 15 cent double edge blade any time I please.

I use paper for test cutting too, but know the one you use will tremendously affect the difficulty of the cut. Heavyweight copier paper is trivially easy to slice, while thinner and harder papers are more difficult. Weak but fibrous papers as much or more. Those chasing ultimate sharpness like cigarette paper, strict push cuts no less, and the late Dr. Vadim Kraichuk put together

a sharpness chart using it. I use thin, glossy pages from one old catalog which keeps it consistent. It is more difficult than receipt paper but presumably not as difficult as the tracing paper shown in the video you referenced. The paper will show dull spots in the edge where it snags or drags as you slice; you can feel this even if the slice does not stall.

You can also use paper to check for slicing aggression: roll a page into a loose tube and try slicing into the side of it at an angle.

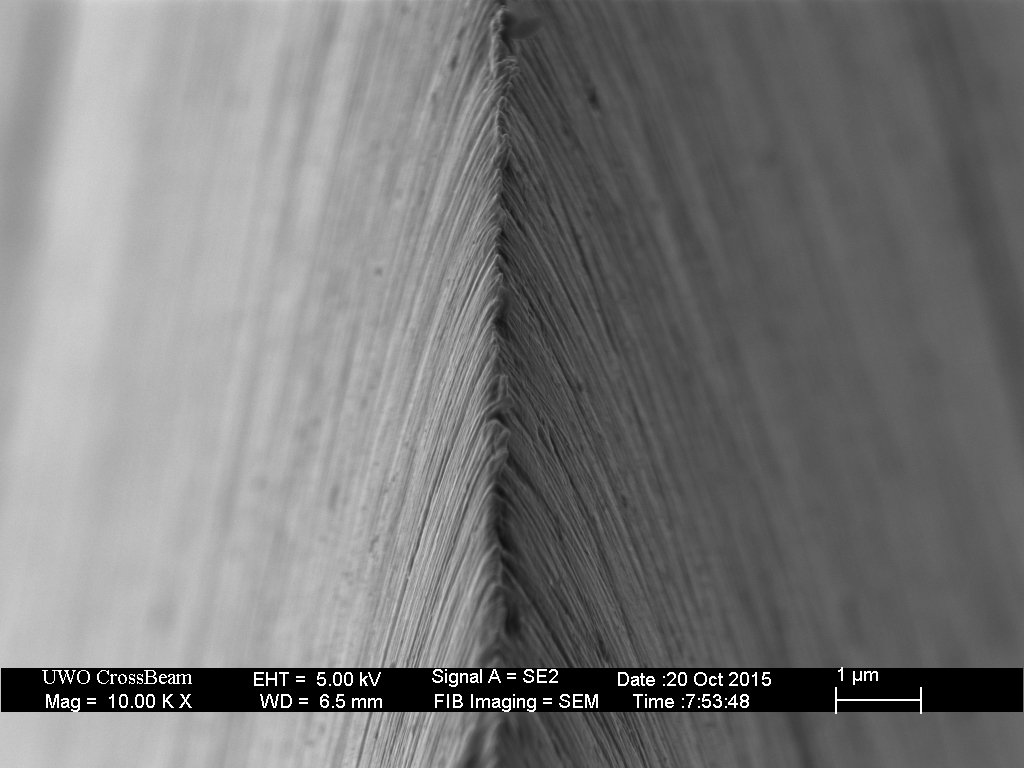

Magnification is tricky. On the one hand any magnification is useful to see more than you otherwise could. On the other even high end optical microscopes cannot fully resolve the detail of the apex as the scale is below the wavelength of visible light. Sometimes simple proxies are as good as hobby-level magnification; shining a bright point source of light directly onto the edge and looking for reflection for example. With a sufficiently bright light you can see the reflection from something much smaller than the eye can resolve by angular acuity, just as you can see light from distant stars.

If you use actual razor blades as a reference you need to be mindful of the fact that they have excellent geometry for push cutting, being very thin and having an acute edge. While thin paper helps to minimize this geometry advantage some remains, and you shouldn't be disappointed if a pocket knife does not perform similarly.

On paring knives is it the belly and tip you struggle with, or the flat as well? What is the steel of the paring knife and of the larger blade you are comparing? Soft stainless can be difficult to deburr.