These are the ones that came with my latest purchase.You're welcome.

Which "cheapo" stones are these?

The diamond stones I bought separately (The SSATC) are actually pretty good.

Way better than those that came with the Lansky IMO.

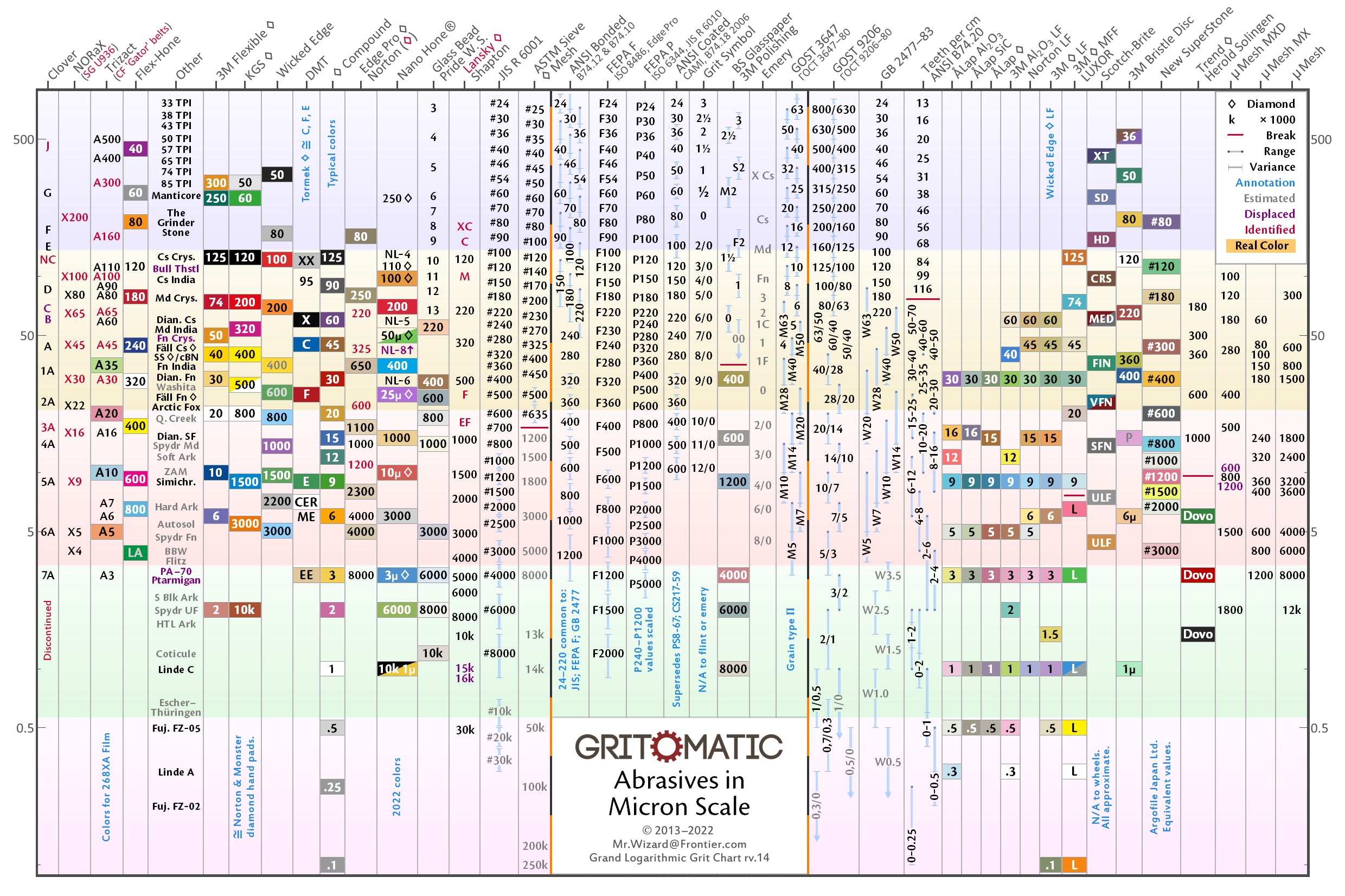

With burr reduction methods and stropping on plain paper (no compound) you should be able to shave arm hair from a stone in the F320 or JIS #400 range.

I can see how that'd be possible ... maybe by varying pressure.

Also, I noticed that the TS Prof goes "with the grain" (parallel the edge) vs fixed angle which go across it.

If I'm not mistaken ... was it you who said that across it was superior? Either way ... I use diagonal strokes that vary between each stone's grit so I can see when I've removed the previous grit's scratches.

Good info.I use paper for test cutting too, but know the one you use will tremendously affect the difficulty of the cut.

Very cool. I'll check this out! lol. It's amazing how deep this subject goes.The late Dr. Vadim Kraichuk put together a sharpness chart using it.

Magnification is tricky. On the one hand any magnification is useful to see more than you otherwise could. On the other even high end optical microscopes cannot fully resolve the detail of the apex as the scale is below the wavelength of visible light. Sometimes simple proxies are as good as hobby-level magnification; shining a bright point source of light directly onto the edge and looking for reflection for example. With a sufficiently bright light you can see the reflection from something much smaller than the eye can resolve by angular acuity, just as you can see light from distant stars.

I have a bunch of magnification options to include a stereo simulfocal microscope and a good camera that goes up to 40x (but I can use whichever magnification I want ... it's just a trade off between field of view vs detail). But ... I was just using a magnifying lens and or a headset which has magnification lenses.

You know ... I've considered buying something kinda like dental loupes that go over your eyes just to see how they work.

I had a business that did SMD // SMT rework (repairing electronics like motherboards, data recovery, etc).

On paring knives is it the belly and tip you struggle with, or the flat as well? What is the steel of the paring knife and of the larger blade you are comparing? Soft stainless can be difficult to deburr.

I think it's just kinda soft steel.

But since you mention it, I think it's where the rate of curve changes (approaching the tip).

I cannot believe how much you know about this topic dude.