- Joined

- Dec 21, 2006

- Messages

- 3,158

I was hoping you guys could "edumicate" me on scratch patterns when sharpening knives. My whole life I never gave it a thought, to change directions when sharpening. I used to use simple straight across the stone motions, like back and forth for heavy material removal. Once the edge was established I would go to the usual sweeping motion starting at the ricasso area, sweeping down and finishing off at the tip area.

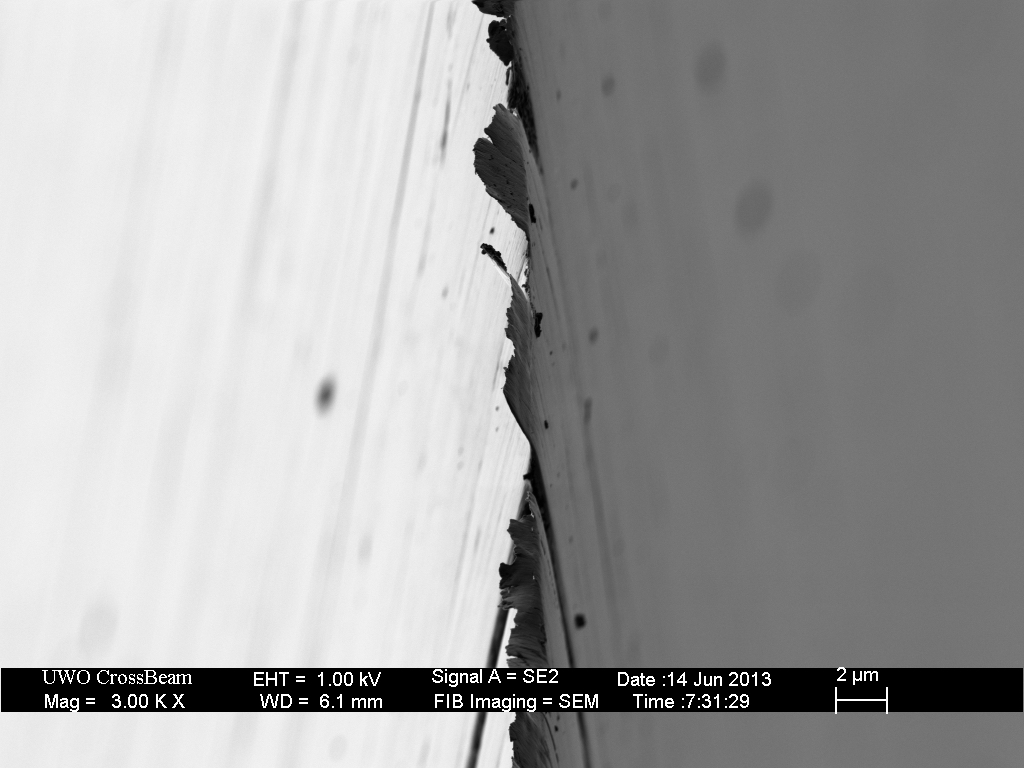

I came across a thread where it was mentioned to change that sweep and go the other direction, like start with the tip and then end at ricasso. I hope that makes sense. Basically, whatever scratch pattern you get when sharpening, make the scratches go the other way as well.

I think I remember a term called "cut bias" or something like that. If all the sharpening was done in one direction, then the micro scratches along the edge will cause a "bias" when slice cutting one way or the other. The idea being to minimize this "bias" by alternating your stroke directions.

What do you guys think about that? Is it noticeable in a fine polished edge, or is this more for the "toothy" edges? Do you do this very thing, alternating directions because of the scratch pattern?

Just curious is all. Just came across this concept and was hoping to get your input. Thanks so much!

I came across a thread where it was mentioned to change that sweep and go the other direction, like start with the tip and then end at ricasso. I hope that makes sense. Basically, whatever scratch pattern you get when sharpening, make the scratches go the other way as well.

I think I remember a term called "cut bias" or something like that. If all the sharpening was done in one direction, then the micro scratches along the edge will cause a "bias" when slice cutting one way or the other. The idea being to minimize this "bias" by alternating your stroke directions.

What do you guys think about that? Is it noticeable in a fine polished edge, or is this more for the "toothy" edges? Do you do this very thing, alternating directions because of the scratch pattern?

Just curious is all. Just came across this concept and was hoping to get your input. Thanks so much!