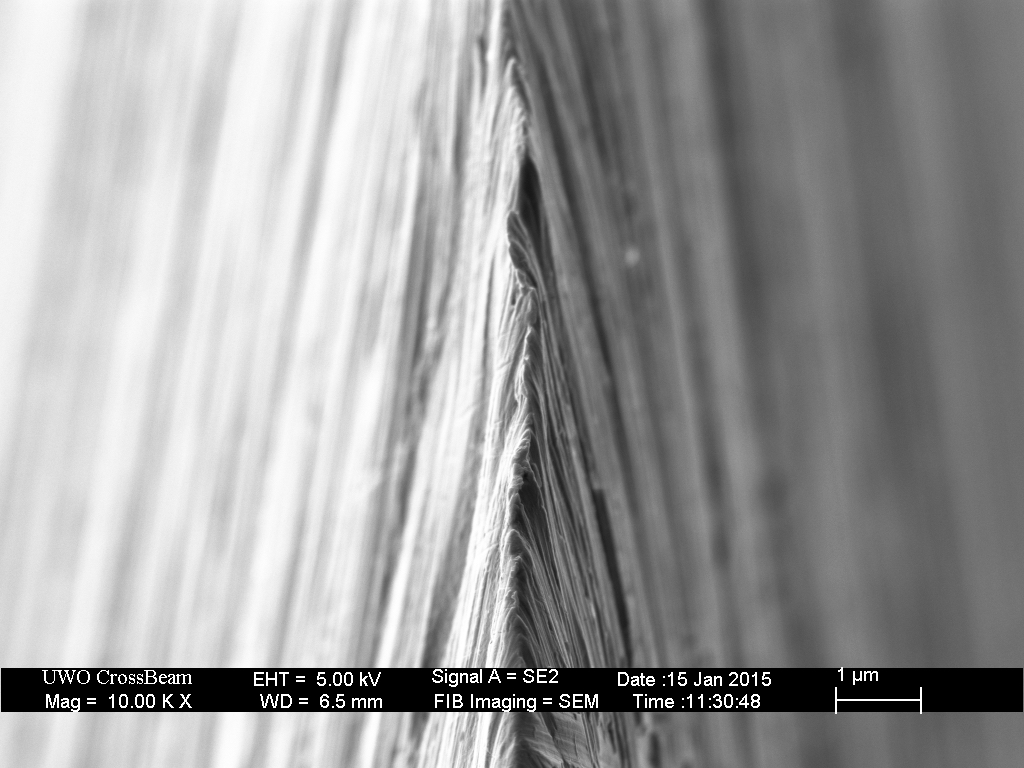

I tried honing a razor one a DMT 1200 at 45 degrees. Is this toothy?

It appears from my perspective that the "toothy" edge is there (and has been, but being hidden by other factors), and it is becoming more evident as your strokes and resultant scratch pattern are evolving into more parallel strokes/pattern.

After your first images I was thinking the non-parallel stroke/scratch was really interrupting an even edge pattern. Others I think also picked up on this.

When the strokes pattern changes is when the wavy edge fallout is happening (from my experience, this I'd what I am seeing as the photos are evolving through this thread). The photos in this thread appear to confirm this and are similar to my experiences.

Additionally, as the pattern is becoming more consistent (in recent posts) it appears other things are showing themselves (that were also contributors to earlier photos of uneven wavey edge).

Appears either the stone(s) have differential grit size or metal swarth buildup is causing irregular scratch depth & pattern. Possibly your stone(s) need surfacing (or evening - typical on my DMT's and especially my last Tan 8k DTM that took surfacibg & few sharpening to finally calm down & smooth out).

As far as swarth build up on stones, cleaning the stones comes to mind first. I clean my DMT's minimally after each sharpening and typically progressively as they are being used on a knife (each grit cleaned before moving blade sides and also b4 the last few light passes on each edge. I have typically just scrubbed them under water with a little soap, and have recently began using a strong magnet to pull the steel swarth from my diamond stones.

Some knives don't get this same level of attention (stone cleaning during sharpening). But, the one's that do seem to have noticeably superior edge retention, life, and reduced maintenance. Effectively, a better life-cycle-sharpening-time-value, provided the user does not abuse the edge (cutting on ceramic plates, impacting staples, concrete, etc :-o

I think also, as other have stated, the specific metal you are sharpening on may also be contributor factor to your results.

Hopefully something here is of some value. Wonderful imagery! Looking fwd to following this threads progression as very interested to "see" how the answers evolve.

Regards & thanks,

Chris