- Joined

- Mar 12, 2012

- Messages

- 1,473

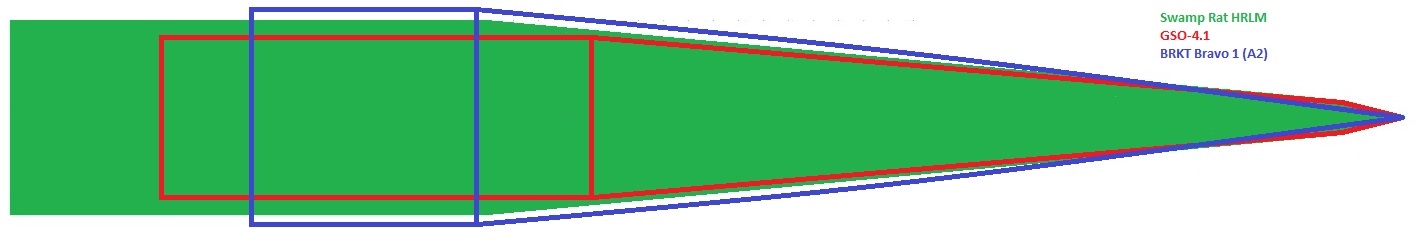

Before going into ergonomics, let's look at geometry and edge durability.

All of these knives are promoted as suitable for "hard use".

BRKT promotes the Bravo 1 as "a Heavy Duty Bushcraft/Survival Knife that can stand up to Abusive use in Real Time Situations." Destruction tests have challenged this assertion, demonstrating that the thin-edge on the Bravo 1 may deform and fracture under very hard use where thicker edges (0.030") will not. This may explain why the 3V versions have thicker edges even though they are made from tougher steel. This knife could be re-beveled for higher durability at a loss of cutting performance. The stock and spine are very thick at 0.22", the tip very robust, able to withstand heavy prying and lateral stress. As a trade-off, the thick spine increases the knife's tendency to wedge in tough materials (e.g. wood, kydex, sheet metal, etc.) where deeper cuts may be required. A trapped blade can result in edge-torque and damage when the edge is too thin. The thinner GSO-4.1 and HRLM are less prone to wedging on deep cuts, and their thicker edges (0.030") are less susceptible to torque, improving performance as "hard use" tools. This comes at the cost of cutting efficiency - the initial force required to complete a cut 3/4"-deep with the Bravo 1 is far lower than is required for the other two. For higher cutting performance, the edges of these two could be thinned by knocking off the bevel shoulders, at the risk of reduced edge-durability against lateral stress.

Keep in mind that an edge bent out of alignment is more susceptible to catastrophic failure, which is not so easy to repair. Sometimes trading cutting efficiency for edge strength can make the difference between a knife that cuts, albeit poorly, and a knife that is broken, i.e. no knife at all.

A note on performance, the satin Bravo 1 and tumbled GSO-4.1 slide more easily through cutting mediums than the coated HRLM which tends to drag.

When an edge is thin and cutting efficiency is wonderfully high, loss of sharpness due to edge-wear is more noticable, especially on hard or abrasive materials (e.g. animal hide, dirty rope, sandy environments) - cuts become ragged, tearing. However, that thin edge can be restored more quickly & easily than a thicker edge. With a good strop & abrasives, thin M390 and CPM-3V at 60 Rc are not much more difficult to sharpen than A-2 at 59 Rc, but the wear-resistance is many times higher, requiring repair less often. SR101, a version of 52100, is also touted to be superior.

I strongly disagree with this statement. In my experience the thicker spine convex blade of Bravo splits wood and other materials far better than thinner spine saber/ flat knives. I have never noticed the thick convex geometry of Bravo ever wedged in wood it splits it and pushes it apart with less effort than saber / flat blade knives with thinner stock that do in fact tend to wedge in wood. GSO's blade stock and geometry will make it more prone to wedging than Bravo.