chiral.grolim

Universal Kydex Sheath Extension

- Joined

- Dec 2, 2008

- Messages

- 6,422

Survive! Knives GSO-5.1

Guy Seiferd's Survive! Knives is growing - he now has a few dealers, production is increased though delays are still common - patience required!

One of his latest offerings was the next generation GSO-5.1 (pre-ordered 2/25/2013, delivered 8/21/2013 ):

Length: 10.62" OAL = 5.73" blade (5.37" cutting edge from heel to tip) + 4.72" handle + 1/8" extended pommel

Blade Height: 1.5" = 0.55" saber flat + 0.91" primary-bevel (down to 0.69" in the sweep) + 0.04" edge bevel

Thickness: 3/16" spine down to 0.020" edge shoulder (0.040" in the sweep for increased durability) , ~5 DPS primary bevel and 14+DPS edge angle.

Weight: 11.2 oz knife + 3.75 oz sheath.

Materials: CPM-3V steel @ 60Rc, canvas micarta scales (other options/colors available)

Standard Price: $239.00 + 15.00 s/h = $254.00 USD

The saber-grind drop-point blade is CPM-3V steel hardened and tempered to 60RC by Peter's Heat Treat in PA for edge-retention (higher than D2), strength, and impact resistance (95J per Charpy C-notch, almost 2X that of A2, almost 3x that of D2).

The tumbled/stonewash finish is beautiful, the edge is evenly ground to an aggressive 320 grit, ~15 dps edge only 0.020" thick behind a 0.040"-wide bevel, thinner than the recent GSO-4.1 batch. Some 4.1 users complained about the thick edge while others expected it for a "hard use" blade. By thinning the edge on a longer knife, Guy is pushing for increased cutting ability. One could still knock the shoulders off and bring the edge thinner, but this is intended as a "hard use" tool - geometries much lower increase the risk of edge failure due to impact and lateral stress.

CPM-3V evinces impressive corrosion resistence for a "non-stainless" tool steel, but bare steel will evince surface spotting if not cared for (as I experienced with my GSO-10). Guy coats all of his bare-steel knives with a thin layer of mineral oil before shipment. He also offers DLC and FDE coatings that are said to be very durable, do not significantly increase 'drag', and may prove beneficial for those in high-salt and humid environments.

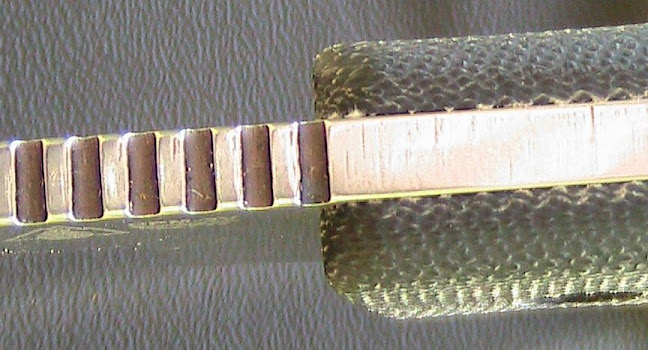

As on Guy's previous offerings, the perimeter of the blade retains the marks of laser-cutting. The edges are champhered for comfort, my preference, so they won't throw sparks from a ferro-rod but Guy offers as a service to cut a spine ferro-notch for those that prefer to not carry some other scraper. ~1" of the spine also features the same 1/8" groove/plateau thumb-jimping found on the GSO-4.1 and Necker, sharp enough at the ridges to catch skin for good retention without being uncomfortable.

Guy Seiferd's Survive! Knives is growing - he now has a few dealers, production is increased though delays are still common - patience required!

One of his latest offerings was the next generation GSO-5.1 (pre-ordered 2/25/2013, delivered 8/21/2013 ):

Length: 10.62" OAL = 5.73" blade (5.37" cutting edge from heel to tip) + 4.72" handle + 1/8" extended pommel

Blade Height: 1.5" = 0.55" saber flat + 0.91" primary-bevel (down to 0.69" in the sweep) + 0.04" edge bevel

Thickness: 3/16" spine down to 0.020" edge shoulder (0.040" in the sweep for increased durability) , ~5 DPS primary bevel and 14+DPS edge angle.

Weight: 11.2 oz knife + 3.75 oz sheath.

Materials: CPM-3V steel @ 60Rc, canvas micarta scales (other options/colors available)

Standard Price: $239.00 + 15.00 s/h = $254.00 USD

The saber-grind drop-point blade is CPM-3V steel hardened and tempered to 60RC by Peter's Heat Treat in PA for edge-retention (higher than D2), strength, and impact resistance (95J per Charpy C-notch, almost 2X that of A2, almost 3x that of D2).

The tumbled/stonewash finish is beautiful, the edge is evenly ground to an aggressive 320 grit, ~15 dps edge only 0.020" thick behind a 0.040"-wide bevel, thinner than the recent GSO-4.1 batch. Some 4.1 users complained about the thick edge while others expected it for a "hard use" blade. By thinning the edge on a longer knife, Guy is pushing for increased cutting ability. One could still knock the shoulders off and bring the edge thinner, but this is intended as a "hard use" tool - geometries much lower increase the risk of edge failure due to impact and lateral stress.

CPM-3V evinces impressive corrosion resistence for a "non-stainless" tool steel, but bare steel will evince surface spotting if not cared for (as I experienced with my GSO-10). Guy coats all of his bare-steel knives with a thin layer of mineral oil before shipment. He also offers DLC and FDE coatings that are said to be very durable, do not significantly increase 'drag', and may prove beneficial for those in high-salt and humid environments.

As on Guy's previous offerings, the perimeter of the blade retains the marks of laser-cutting. The edges are champhered for comfort, my preference, so they won't throw sparks from a ferro-rod but Guy offers as a service to cut a spine ferro-notch for those that prefer to not carry some other scraper. ~1" of the spine also features the same 1/8" groove/plateau thumb-jimping found on the GSO-4.1 and Necker, sharp enough at the ridges to catch skin for good retention without being uncomfortable.