Square_peg

Gold Member

- Joined

- Feb 1, 2012

- Messages

- 13,853

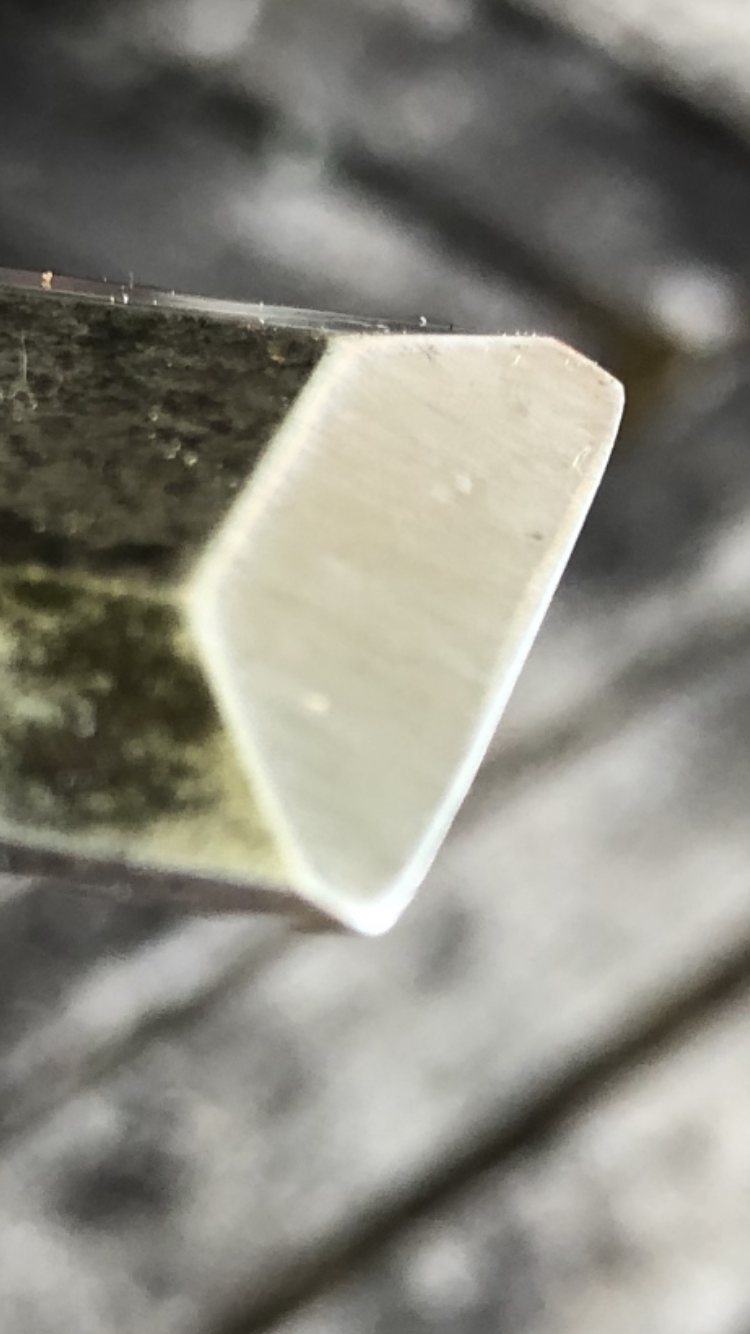

Almost any file will seem 'no good' when it first meets the oxidation layer of an old axe. But you can start in one corner and slowly work your file through that layer. Then work out from there, lifting the oxidation layer with the slightly softer steel below the immediate surface.

If you find an axe that files reasonably well then test some of your old files against that.

If you find an axe that files reasonably well then test some of your old files against that.

Last edited:

WedgeWork

WedgeWork