-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop? Show us whats going on, and talk a bit about your work!

- Thread starter WillSwift

- Start date

Here's a few getting prepped for heat treat. I still need to grind some tang hollows and other tidbits of work. New to me medium and small choppers and large and medium fighter styles that I think I'll call my "fangers" since I like to make up words. The first two pics are 5160 and the hidden tangs are 52100. I've got more but don't want to clutter up a post. I typically go to 600 grit pre HT and Paul Bos sends them back so clean I usually can start right up at 600 quick clean up and go from there. Comments/critique welcome as always!View attachment 1145618 View attachment 1145619 View attachment 1145620

Thanks for looking,

John Cahoon

You ticked all the boxes on that top chopper in the second pic, nice looking blade!

I really like the amount of ricasso and choil you put on your blades. Very sound design

Alex Topfer

Gold Member

- Joined

- May 1, 2019

- Messages

- 767

I'm trying to work out if I need to oil this handle? It's iron bark, it's a kitchen knife

(edit: there are some scratches at the front I need to fix first)

(edit: there are some scratches at the front I need to fix first)

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 38,405

Nice blade Alex. I am not sold on the handle being right. The end shouldn't get smaller. It also looks pretty round. Both those reduce control.

I would have used a wa shape handle, but a western one is OK if it has a good grip and control.

Another thing is I usually put a tiny heel flat on that very sharp point which is right where your fingers will be.

The camera angle makes it hard to guess size, what are the measurements of the blade and the handle?

I would have used a wa shape handle, but a western one is OK if it has a good grip and control.

Another thing is I usually put a tiny heel flat on that very sharp point which is right where your fingers will be.

The camera angle makes it hard to guess size, what are the measurements of the blade and the handle?

Alex Topfer

Gold Member

- Joined

- May 1, 2019

- Messages

- 767

Thanks Stacy.

The photos don't show the shape of the handle well, it's D with a large flat on the left side. I think it will be ok, but it's a knife for me so if it doesn't work I'll try again. I would have done a more traditional wa shape if i weren't using it, but i decided to get a little experimental. The rounded bit at the back sits out behind my hand, I though with the angles in the blade a really square handle wouldn't look right

The heel flat is a good idea, I'll do that when I sharpen it tonight.

overall length is about 27cm (~11 inch), 15cm (6") blade, 12 (5") cm handle.The camera angle makes it hard to guess size, what are the measurements of the blade and the handle?

The photos don't show the shape of the handle well, it's D with a large flat on the left side. I think it will be ok, but it's a knife for me so if it doesn't work I'll try again. I would have done a more traditional wa shape if i weren't using it, but i decided to get a little experimental. The rounded bit at the back sits out behind my hand, I though with the angles in the blade a really square handle wouldn't look right

The heel flat is a good idea, I'll do that when I sharpen it tonight.

- Joined

- Feb 18, 2016

- Messages

- 2,209

Got 2 chef knives profiled out ready to heat treat a couple of days ago.

Problem is my DESPERATELY needed to be done. So I did what people said not to do and made a new forge out of just kastolite. Durable? yes functional? Nope. So had to tear it apart and do it the right way.

Got 2in of kaowool, some rigidizer, and used kastolite to seal the wool. Hopefully its dried by tomorrow so I can fire up the forge and test it out

Problem is my DESPERATELY needed to be done. So I did what people said not to do and made a new forge out of just kastolite. Durable? yes functional? Nope. So had to tear it apart and do it the right way.

Got 2in of kaowool, some rigidizer, and used kastolite to seal the wool. Hopefully its dried by tomorrow so I can fire up the forge and test it out

Alex Topfer

Gold Member

- Joined

- May 1, 2019

- Messages

- 767

Here's a shot showing the profile of that handle.

Also the seam where I glued it and a small burn Iron bark end grain seems to burn really easy

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 38,405

A "D" handle is basically a triangular handle that you flatten one side with a very low arc, and make the top a similar arc that tips to a ridge. The curve from the ridge to the bottom is more pronounced. Look at #13,19, and20 in the images and you can see the ridge. I attached a quick sketch of the basic idea.

A "D" handle is basically a triangular handle that you flatten one side with a very low arc, and make the top a similar arc that tips to a ridge. The curve from the ridge to the bottom is more pronounced. Look at #13,19, and20 in the images and you can see the ridge. I attached a quick sketch of the basic idea.

Last edited:

Alex Topfer

Gold Member

- Joined

- May 1, 2019

- Messages

- 767

Where is the plane of the blade in relation to those? I'm having trouble picturing how it exists as a 3d object.

Maybe I just need to buy one so I can hold it in my hands.

Maybe I just need to buy one so I can hold it in my hands.

torqueguy

Pocket Puukko

- Joined

- Oct 19, 2007

- Messages

- 234

- Joined

- Dec 22, 2015

- Messages

- 11

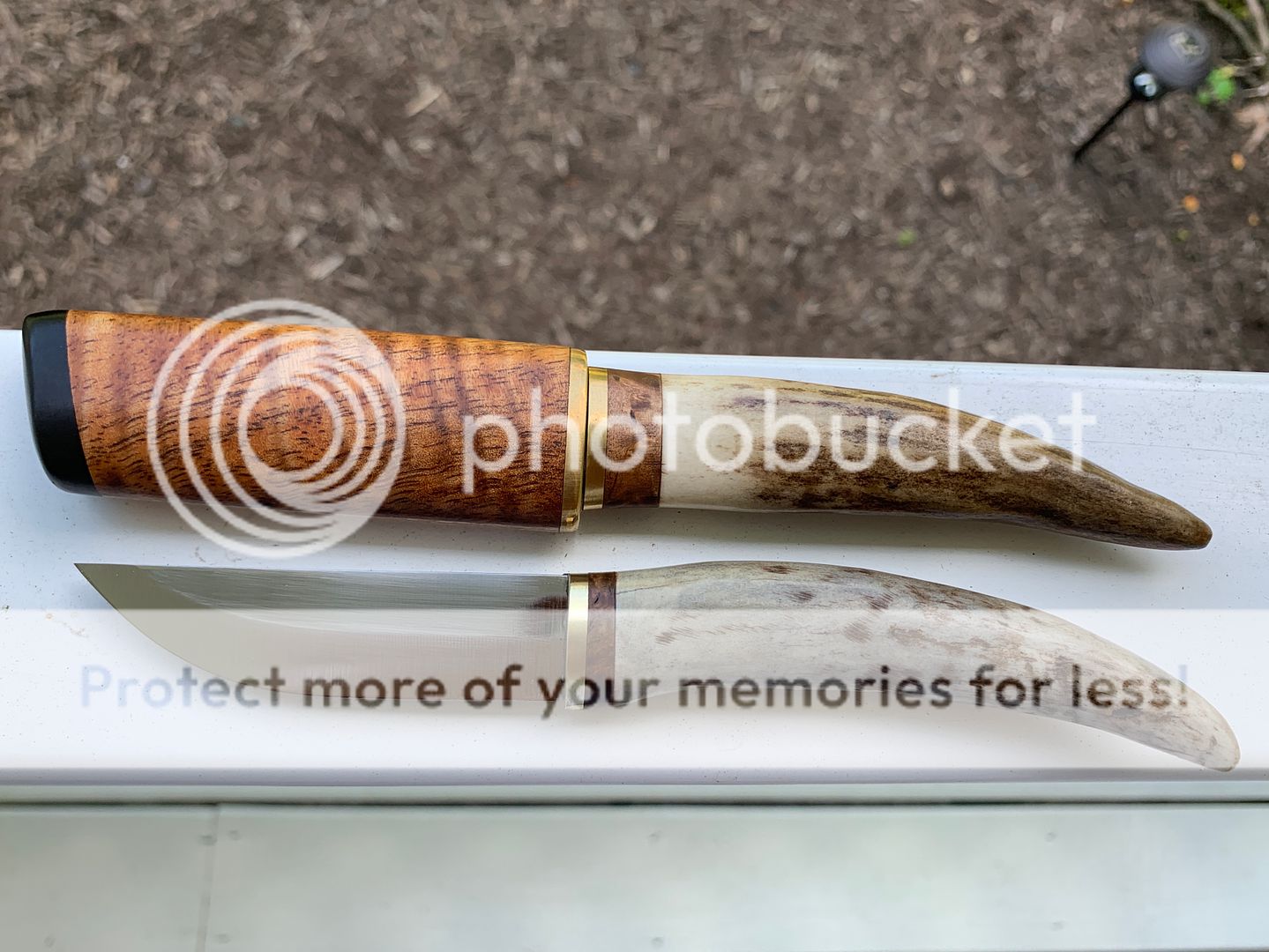

https://imgur.com/a/6UbOpiG

8"fillet knife made out of S90V. 61 HRc with desert ironwood handle and nickle silver finger guard.

Last edited:

torqueguy

Pocket Puukko

- Joined

- Oct 19, 2007

- Messages

- 234

Gorgeous woodhttps://imgur.com/a/6UbOpiG

8"fillet knife made out of S90V. 61 HRc with desert ironwood handle and nickle silver finger guard.

Where is the plane of the blade in relation to those? I'm having trouble picturing how it exists as a 3d object.

Maybe I just need to buy one so I can hold it in my hands.

I know you were asking Stacy but here's a pic in case he don't get back to you... On the knife below, this is a D handle placed for a lefty (the pointy side goes towards the fingers instead of the palm):

Looking at the handle from the butt end: