am writing this after each test as it happens so that it is fresh, as it may take many days in order for me to feel I have a satisfactory review.

I received the offer from Luong La (bluntcut) to test a knife after I contacted him wanting to know when he will be taking orders, we discussed design and steel a bit, and after a quick google search, Cru Forge V seemed somewhat untested yet very promising. I told him I couldn't make any promises in regard to the quality of my tests, and asked him what he wanted me to test, and he told me that it was completely up to me. I didn't expect much, a rough handled cutout more or less to be sent out when he could find the time, but just over a week from our first contact he sent it out. It came in a priority mail flat rate. I opened it up, and I have to admit I was legitimately surprised, it came with a kydex sheath, which looked quite well done, and the handle was a single piece of wood which appeared to be milled out to slot the tang, it looked and felt designed for my size of hand, which most likely was a coincidence, but was very nice. and was not simply a tube of wood but was shaped and contoured, the wood itself was quite beautiful as well.

Cruforge V is somewhat similar to 52100 but with less chromium and more vanadium, It was intended to combine the forgability, keenness, and toughness of 10xx steels but have much better edge retention. With super quenching I believe the goal is to create a steel that is able to retain a high level of hardness, but have a very fine tough grain structure.

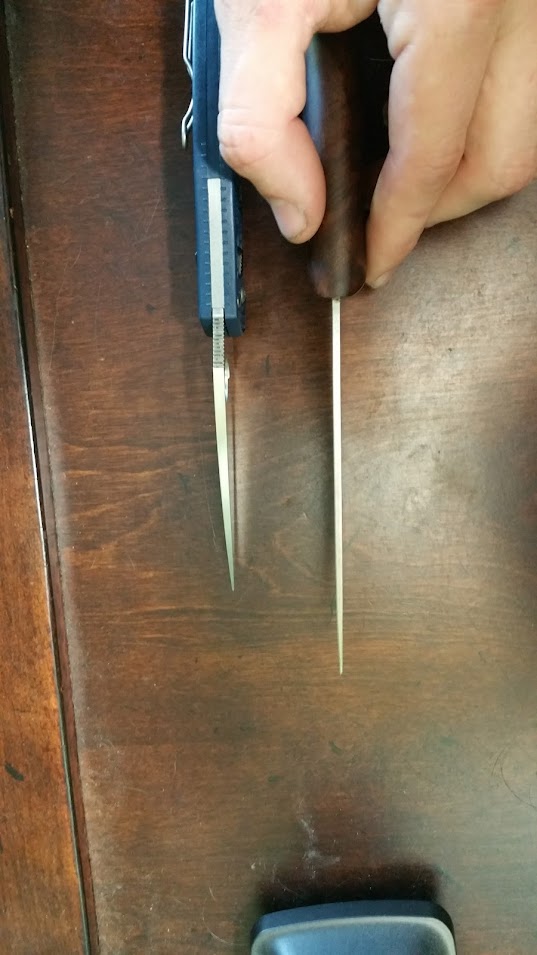

I mentioned wanting a thin slicer, primarily because I felt a thin hard knife that could handle hard use was much more useful than a half inch prybar that can split a tank. But thin this thing is, less than 2.5mm and around 2.5 oz. It looked like it would be a perfect skinning knife.

Although I had decided to profile it for consistency before testing it I did play with the edge he freehanded, it was quite sharp. Push cut pb paper with ease. Caught arm hair, and even shaved. Although not near as well as my PM2 did after heavy stropping.

Now I decided to see what it'll do.

I received the offer from Luong La (bluntcut) to test a knife after I contacted him wanting to know when he will be taking orders, we discussed design and steel a bit, and after a quick google search, Cru Forge V seemed somewhat untested yet very promising. I told him I couldn't make any promises in regard to the quality of my tests, and asked him what he wanted me to test, and he told me that it was completely up to me. I didn't expect much, a rough handled cutout more or less to be sent out when he could find the time, but just over a week from our first contact he sent it out. It came in a priority mail flat rate. I opened it up, and I have to admit I was legitimately surprised, it came with a kydex sheath, which looked quite well done, and the handle was a single piece of wood which appeared to be milled out to slot the tang, it looked and felt designed for my size of hand, which most likely was a coincidence, but was very nice. and was not simply a tube of wood but was shaped and contoured, the wood itself was quite beautiful as well.

Cruforge V is somewhat similar to 52100 but with less chromium and more vanadium, It was intended to combine the forgability, keenness, and toughness of 10xx steels but have much better edge retention. With super quenching I believe the goal is to create a steel that is able to retain a high level of hardness, but have a very fine tough grain structure.

I mentioned wanting a thin slicer, primarily because I felt a thin hard knife that could handle hard use was much more useful than a half inch prybar that can split a tank. But thin this thing is, less than 2.5mm and around 2.5 oz. It looked like it would be a perfect skinning knife.

Although I had decided to profile it for consistency before testing it I did play with the edge he freehanded, it was quite sharp. Push cut pb paper with ease. Caught arm hair, and even shaved. Although not near as well as my PM2 did after heavy stropping.

Now I decided to see what it'll do.

Last edited: