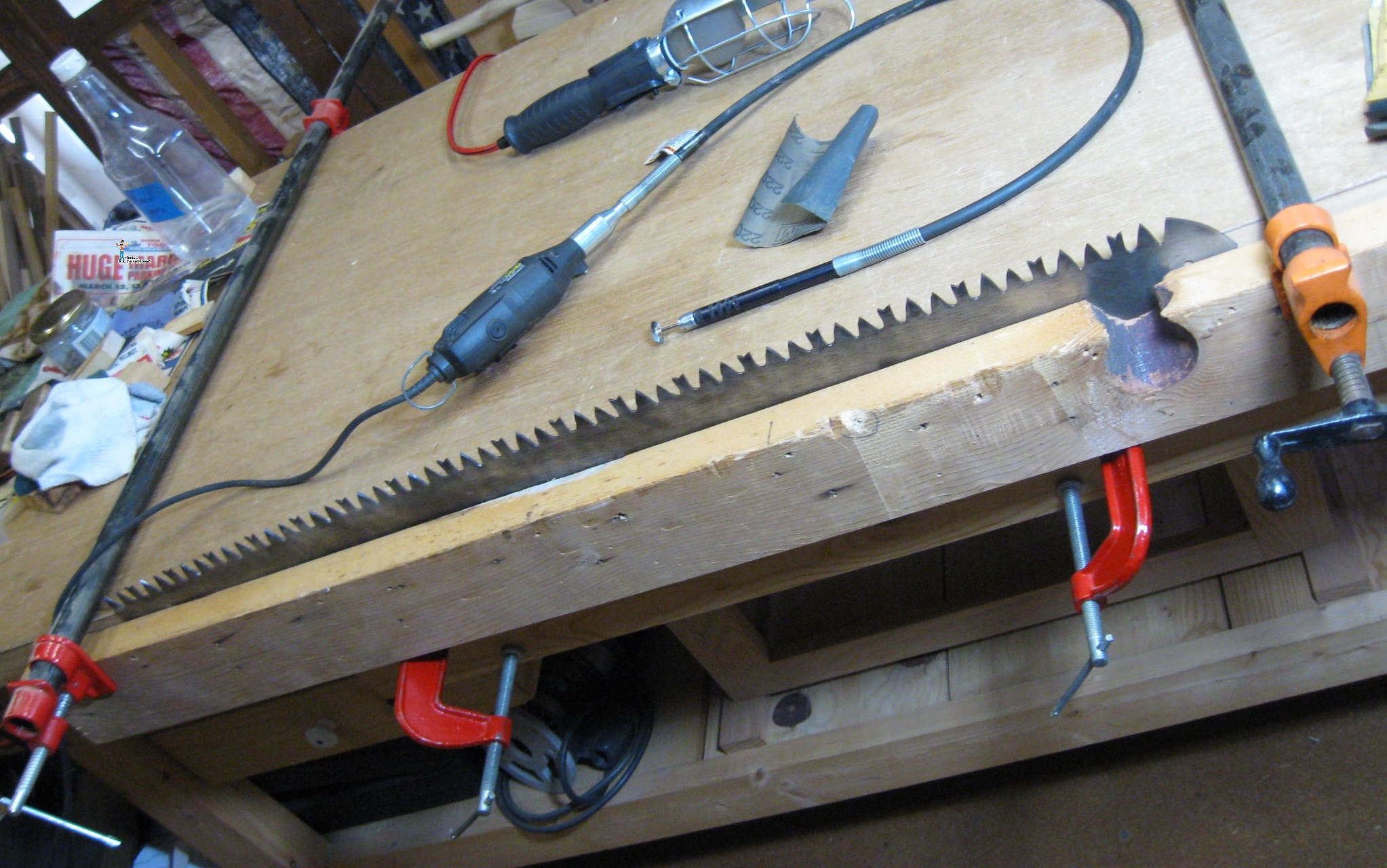

Thank you,i'll look for marks in a sec here...One of the rakers is broken(may've gotten dropped...there's a lot of rough and funky action around here,like in 2013 we were flooded really bad,lots of my tools were submerged for a couple weeks(you may still see silt on some).

That break don't look great,grain-wise...(thinking in terms of setting...especially maybe adjusting back and forth

Man that's a tough one...

...Yes,i noticed dulling pretty much immediately,some flat on the point formed.

It's a bad scene here with silt.Even a green-ish drift-log,with no obvious voids or cracks,can contain silt inside.I've hit a pocket once with a band-mill to where i couldn't even finish the few feet of cut,blade just went.Turned out it was a pocket of densely packed silt,few inches thick,clear inside.

The silt is Basaltic in origin.Glacial age.The entire terrain here is built of it.

Trees go into the river with the banks,during the spring break-up.The ice action skins the bark off,and the then exposed sap picks up silt,a layer of it sticks to it as it dries and catalyses in the water....