Thanks Christian, that’s very interesting. (Sorry, I was replying to another post while you were replying to mine.)

Sounds like a good technique - I pretty much use the same process on most knives albeit with different abrasives. The Naniwa Chosera stones are usually my go-to for carbon steels. I use the same convexing step to clean up the grind lines and blend the edge bevel into the flats a bit. Black emery on a rough strop also works well for this step, I’ve found.

Specifically for the Lambsfoot pattern, I’ve found the Spyderco Sharpmaker to actually be a decent way to reset the edge to 15dps, using the diamond rods. This avoids the errant scratching on the flats, too. It takes a bit more time and patience, of course, and you have to be careful not to run the tip off the stones and round it off, as

@r8shell has pointed out before. This seems to give a more even looking edge bevel on straight edged A. Wright knives than using benchstones, I find.

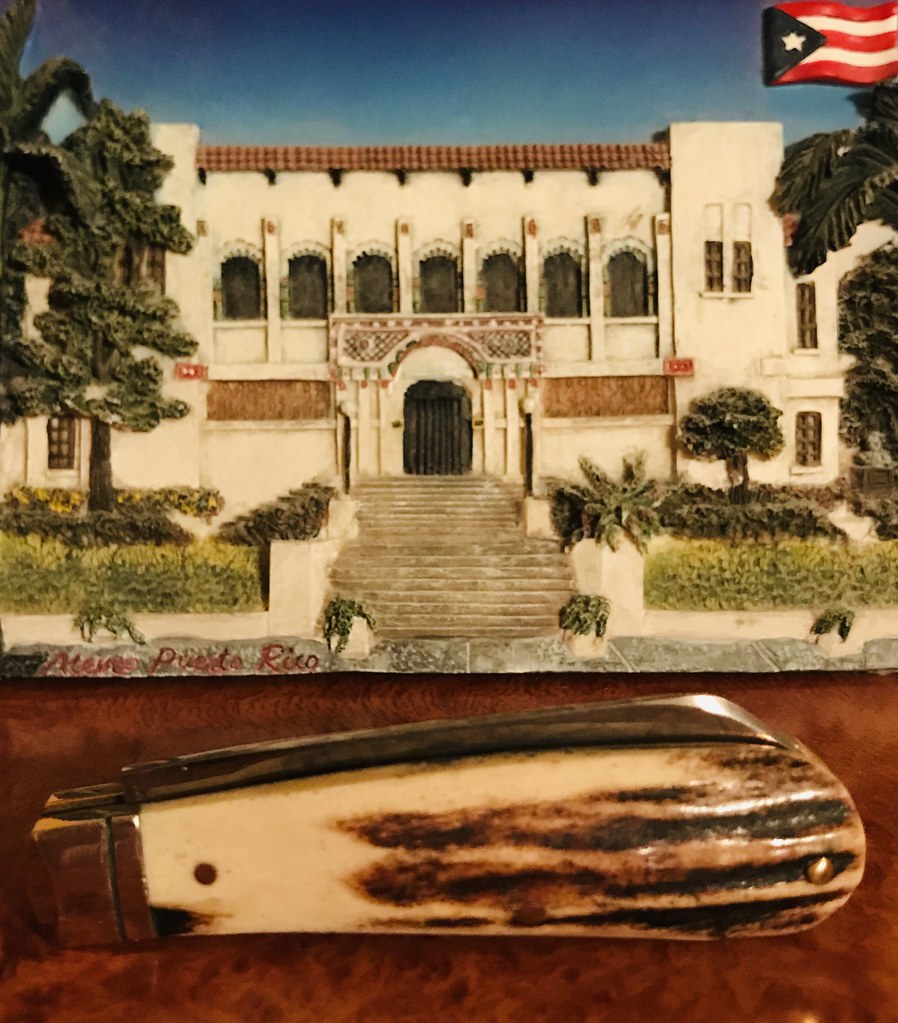

All the below knives have had their edge areas thinned out with this method.

Lately I’ve been playing with the Russian Venev bonded diamond, double sided waterstones, which are excellent. They need to be lapped flat with a bit of loose silicon carbide powder on glass before use, to reach their full potential, but they give a great edge on the Lambsfoot knives.

Their little pocket stone versions (pictured) are a superb way to keep a great, razor keen edge in the field as well. The new CBN/fine ceramic Spyderco Doublestuff excels as a portable touchup stone too, although it’s capable of doing full sharpenings as well.

I’ve also been experimenting with sub micron CBN emulsions on nanocloth, which can achieve literally hairsplitting edges, but that’s probably something for another thread!