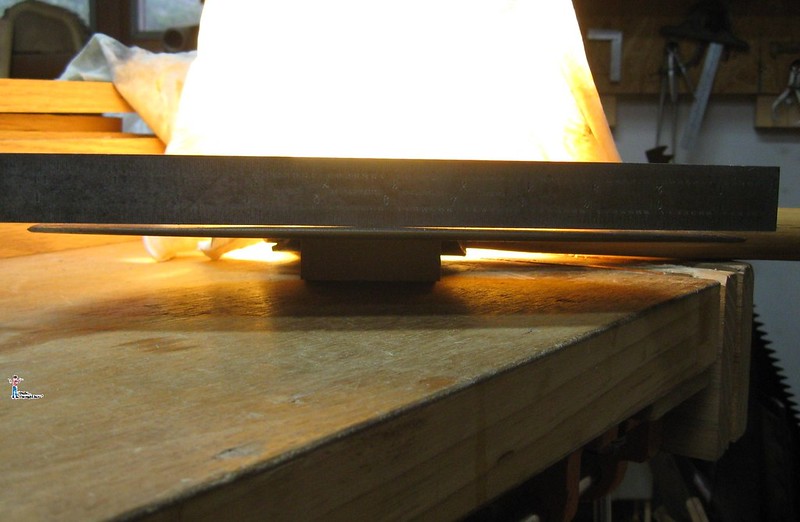

isn't it just bent out of shape? It kinda looks of to me? But then again, i could Be wrong....

I suppose it's possible but I don't see any signs of stress in the metal or deformations, and I'd think that bending steel like that would leave some sort of evidence. Plus the hardened steel at the bit would probably chip or break before bending much.

I've seen a number of nicer broad axes with a similar curvature to them. The idea is that it helps to keep the blade from digging in as you're hewing a beam. My understanding is that in hewing you want the cutting edge's motion to be as close to parallel with the wood surface as possible. Basically you're taking small bits and trying to to keep the blade from really digging in. However, to actually take a bite out of the wood you have to twist the axe slightly so that the cutting edge's motion is pointing a little bit into the wood surface rather than parallel with it. By putting this curve in the flat side of the axe it's easier to keep the angle as close to parallel as possible while still taking a bite because there's less of a chance of the poll hitting the wood and deflecting your strike.

This article was helpful to me when I first tried to figure out how to hew with an axe:

https://pfollansbee.wordpress.com/2012/12/13/the-endless-look-at-hewing-hatchets/

That all said, I'm no expert on hewing so hopefully one of the experts will chime in and correct me if any of that is wrong.

IMG_20170717_144558

IMG_20170717_144558