-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tanto Advice

- Thread starter shamu

- Start date

Ho wood is a magnolia, not a poplar. American substitutes are holly and alder. Poplar is OK for shira-saya, but isn't any good for a working handle.

Thanks for the correction!

Chris

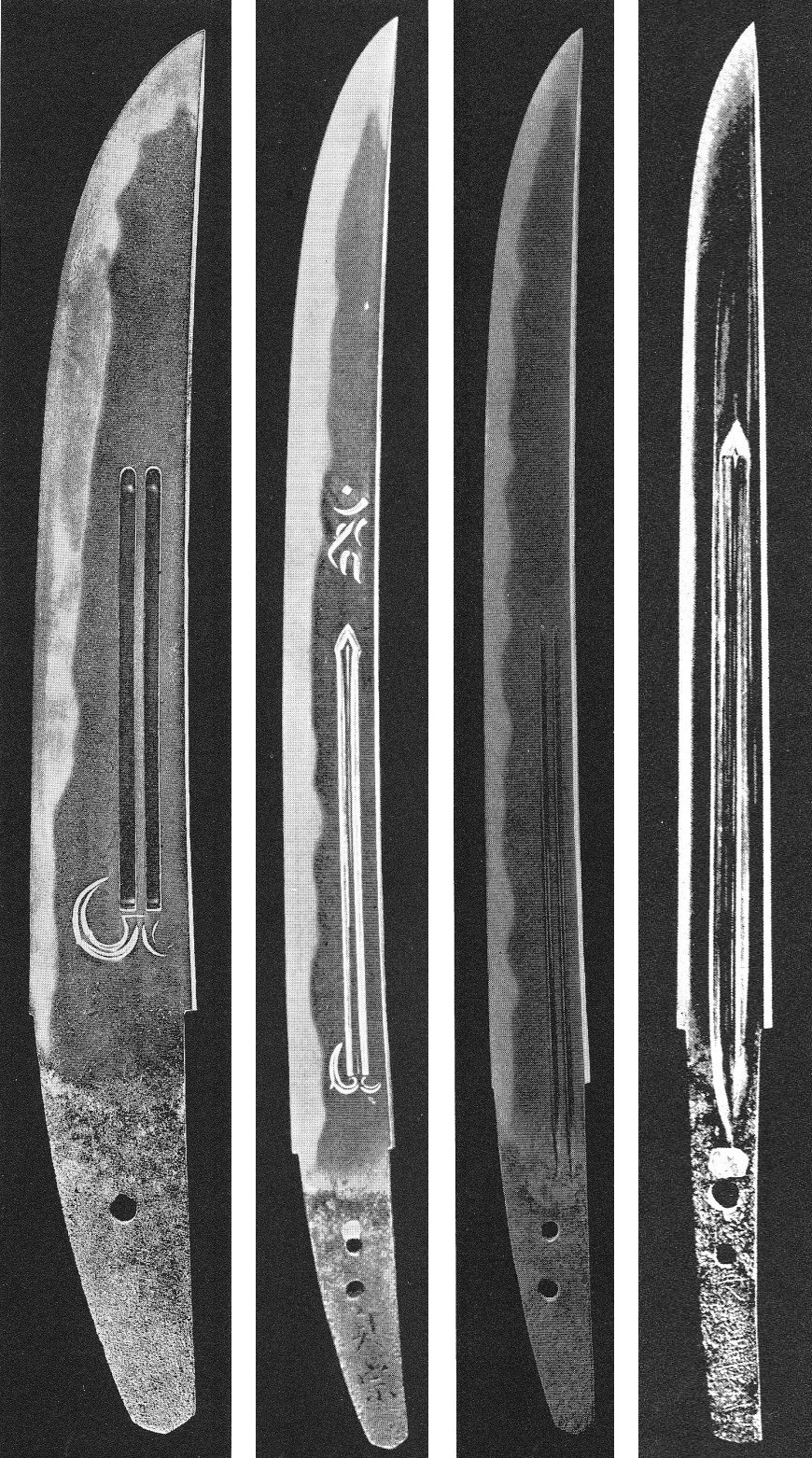

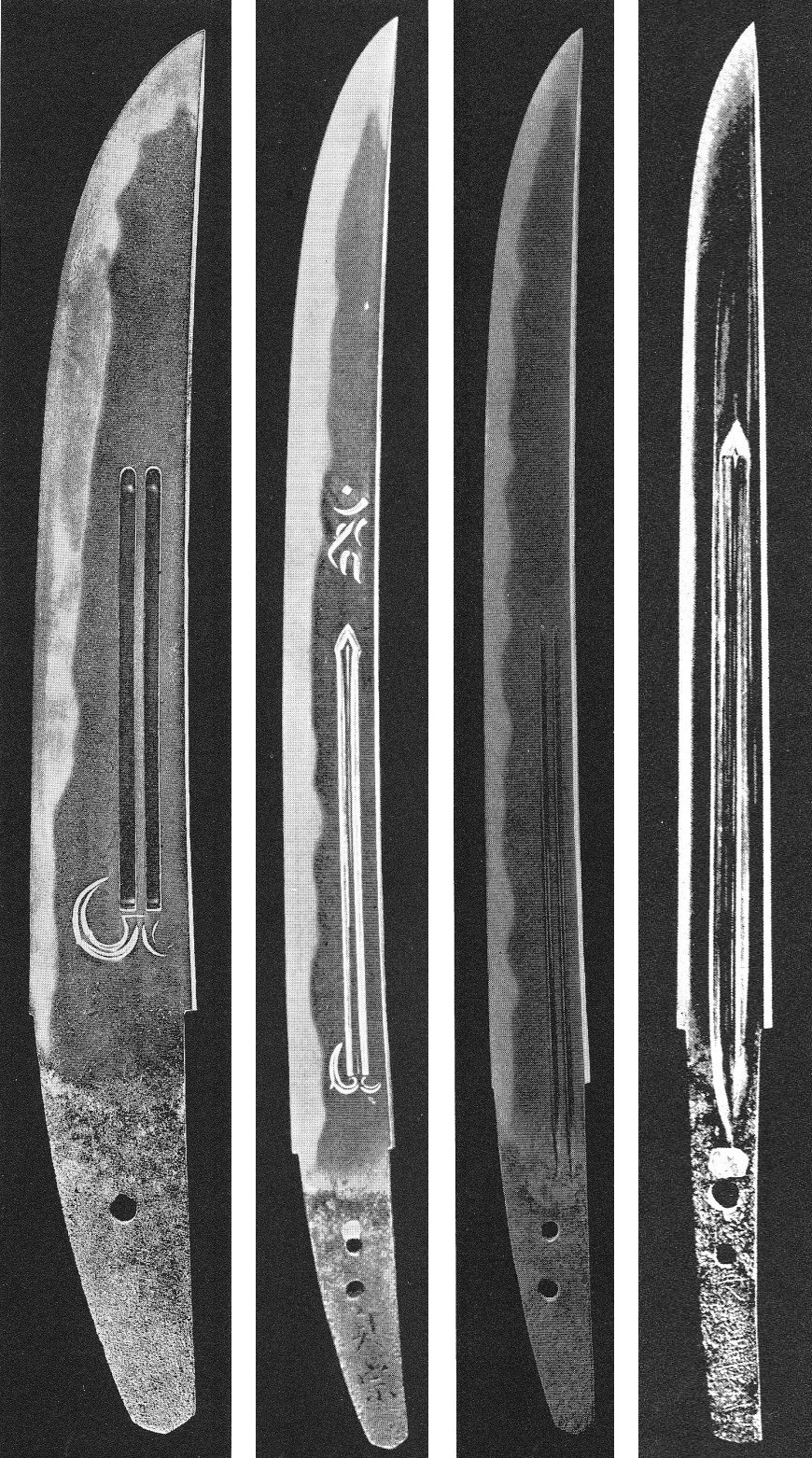

That banana shaped blade you have made is an exaggeration of the form. The link shows what a real Tanto looks like. When working from a forging the lines and planes of the mune are the first things defined. The rest of the shape of the blade are proportioned from that.

https://upload.wikimedia.org/wikipedia/commons/b/b9/Tanto_Hyuga_Masamune.JPG

https://upload.wikimedia.org/wikipedia/commons/b/b9/Tanto_Hyuga_Masamune.JPG

- Joined

- Jan 18, 2010

- Messages

- 217

That banana shaped blade you have made is an exaggeration of the form. The link shows what a real Tanto looks like. When working from a forging the lines and planes of the mune are the first things defined. The rest of the shape of the blade are proportioned from that.

https://upload.wikimedia.org/wikipedia/commons/b/b9/Tanto_Hyuga_Masamune.JPG

Thanks Carcara. I'm seeing conflicting degrees of curvature in my research, but I can definitely reduce some of that exaggeration. I certainly don't think "i nailed it", but some Hira Zukuri have a flatter mune and some have a more curved mune. maybe less curvature at the kissaki? Do you think its too late to shape the mune?

Your designs will continue to be refined as you progress, but I think your latest design is pretty much within historical parameters:

Your curve does appear to be greater near the tip (sakizori), but there is historical precedent for that. You are off to a good start, and I don't have anything else to say about your design at this point. Finish it up and see how it turns out.

Chris

Your curve does appear to be greater near the tip (sakizori), but there is historical precedent for that. You are off to a good start, and I don't have anything else to say about your design at this point. Finish it up and see how it turns out.

Chris

- Joined

- Jan 18, 2010

- Messages

- 217

Thanks Hesparus. I think i'm ready for HT. JT, i sent ya an email!

I got a bit skiddish re: the mune. I'm going to save that for a future blade and maybe practice a bit on scrap. Things also got hairy near what would be the ricasso, but i'm going to grind that out post HT once i have a file guide. It's hard to conceptualize where the blade ends and the tang begins...

now to score some alder. i struck out w/the guitar folks

I got a bit skiddish re: the mune. I'm going to save that for a future blade and maybe practice a bit on scrap. Things also got hairy near what would be the ricasso, but i'm going to grind that out post HT once i have a file guide. It's hard to conceptualize where the blade ends and the tang begins...

now to score some alder. i struck out w/the guitar folks

Last edited:

- Joined

- Jan 18, 2010

- Messages

- 217

Habaki talk...

I will following this tutorial

http://jhbladesmith.com/craft/habaki-making/

anyone think its off-base?

*edited post re: soldering and bar width

I will following this tutorial

http://jhbladesmith.com/craft/habaki-making/

anyone think its off-base?

*edited post re: soldering and bar width

Last edited:

- Joined

- Jan 18, 2010

- Messages

- 217

Definitely you need flux. On copper in particular it also helps to brighten up the surfaces you're going to solder with some sandpaper. Solder won't stick to the oxides on the surface.

Thanks kuraki. i edited my post a bit in case you're wondering. what type of solder/flux is good in an application like this? the tutorial i posted in my edit suggests "hard silver solder". do you have any guidance/tutorials/reading on how to flux for this type of work? i've soldered electrical wires, but im assuming i'm going to set my piece up to be blasted w/my bernzomatic.

- Joined

- Jan 9, 2011

- Messages

- 16,397

@ Daniel

Hope I'm not derailing the thread but what part of the country are you in, alder is pretty rare in Louisiana we have to have it shipped in.

I still have one Tele I built a few years ago for myself, but that one I did with mahogany with a maple cap, andGibson scale length.

I play heritage guitars mostly and occasionally an SG , I don't really get along with strats and teles anymore.

Colorado and I am pretty sure they are shipping it in. Sounds cool on the tele build!

Daniel, you make guitars too?! I'm hoping they're horrible and it baffles you daily...talent hog! j/k of course.

Awful! lol I started by building a cigar box guitar and have gotten carried away!

Looking good on the progress!

You can solder copper with a pretty simple setup, check out youtube for lots on sword fittings. Walter Sorrells has some great videos on Japanese style blades.

kuraki

Fimbulvetr Knifeworks

- Joined

- Jun 17, 2016

- Messages

- 4,679

Thanks kuraki. i edited my post a bit in case you're wondering. what type of solder/flux is good in an application like this? the tutorial i posted in my edit suggests "hard silver solder". do you have any guidance/tutorials/reading on how to flux for this type of work? i've soldered electrical wires, but im assuming i'm going to set my piece up to be blasted w/my bernzomatic.

Traditional japanese styles are really, really outside my lane but that tutorial looks pretty straightforward. A "hard silver solder" will be a high temp solder that you won't be able to do with just a propane plumbers torch. You want a "silver bearing solder" like this:

https://www.amazon.com/Stay-Brite-S...8-7&keywords=stay+brite+silver+bearing+solder

A hard silver joint would be stronger and maybe more preferable for this? But that soft silver bearing solder will be within your capabilities to join those edges and will hold pretty well. This is what a lot of makers use for soldering guards to blades.

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 38,244

Here is the post from the tanto thread. I'll try and find some photos and other info this weekend, since it is likely I will be snowed in.:

Traditional togi is very slow and difficult. Using ha-zuya and ji-zuya is a skill that takes a lot of practice. It also is really rough on the fingertips .... what part of them you don't cut off while your fingers are flying back and forth along the ha.

I use a method blending shiagi-togi and a hybrid polish. I do the foundation steps (shitaji-togi) and etch the blade to get the best hamon activity and look. Instead of going to small finger stones I use 1" squares of high quality SC paper. 800 grit, 1200 grit and 2500 grit are good. I fold them twice to make 1/2" squares with a little thickness. I use these with a fingertip. I turn them over and fold the other way to use all four abrasive surfaces. When it slows down, I chuck it on the floor and grab the next square. In some cases, I use the paper along with a slurry of fine grit SC or AO powder (more or less like nagui). I go for a smooth bright finish on the hardened ha, and a frostier matte finish on the softer ji.

After the surfaces are done, I use powders and compounds as needed to get the right look.

When working right on the edge, I sometimes use a "finger stick". It is a 6" piece of soft wood that has a small leather pad on the end. It is held in the hand and becomes my "finger". Kevlar gloves are also a good idea sometimes. You have to be cautious when wearing them, as they can scratch polished surfaces.

A good trick for getting the ha and ji finished without ruining the hamon is to paint it with fingernail polish. Use a fine tip sable brush and carefully cover the hamon, clouds, and any ashi with the polish (or a fast drying lacquer). Let it dry well and do the shiagi-togi going right up to the paint. This keeps stray grit and oopsies from ruining a well developed hamon. When done, remove the protective paint with acetone or naptha and clean carefully. A tiny amount of touch-up may be needed in a few spots, but the blade is normally done at this point.

Places to NOT try to save money are the polishes, the cleaning supplies, and water. Use high quality paper towels and change them often. Cheap towels can cause scratches. Change the water often. A few drops of Dawn in the oke helps with surface tension. The polishes should be the better grades, not the bargain priced lapping and shop grades.

Traditional togi is very slow and difficult. Using ha-zuya and ji-zuya is a skill that takes a lot of practice. It also is really rough on the fingertips .... what part of them you don't cut off while your fingers are flying back and forth along the ha.

I use a method blending shiagi-togi and a hybrid polish. I do the foundation steps (shitaji-togi) and etch the blade to get the best hamon activity and look. Instead of going to small finger stones I use 1" squares of high quality SC paper. 800 grit, 1200 grit and 2500 grit are good. I fold them twice to make 1/2" squares with a little thickness. I use these with a fingertip. I turn them over and fold the other way to use all four abrasive surfaces. When it slows down, I chuck it on the floor and grab the next square. In some cases, I use the paper along with a slurry of fine grit SC or AO powder (more or less like nagui). I go for a smooth bright finish on the hardened ha, and a frostier matte finish on the softer ji.

After the surfaces are done, I use powders and compounds as needed to get the right look.

When working right on the edge, I sometimes use a "finger stick". It is a 6" piece of soft wood that has a small leather pad on the end. It is held in the hand and becomes my "finger". Kevlar gloves are also a good idea sometimes. You have to be cautious when wearing them, as they can scratch polished surfaces.

A good trick for getting the ha and ji finished without ruining the hamon is to paint it with fingernail polish. Use a fine tip sable brush and carefully cover the hamon, clouds, and any ashi with the polish (or a fast drying lacquer). Let it dry well and do the shiagi-togi going right up to the paint. This keeps stray grit and oopsies from ruining a well developed hamon. When done, remove the protective paint with acetone or naptha and clean carefully. A tiny amount of touch-up may be needed in a few spots, but the blade is normally done at this point.

Places to NOT try to save money are the polishes, the cleaning supplies, and water. Use high quality paper towels and change them often. Cheap towels can cause scratches. Change the water often. A few drops of Dawn in the oke helps with surface tension. The polishes should be the better grades, not the bargain priced lapping and shop grades.

Last edited:

- Joined

- Jan 18, 2010

- Messages

- 217

Looking good! Make sure (if you haven't already) that the nakago tapers right from the machi all the way to the end. Otherwise the habaki won't fit right.

Chris

Thanks Hesparus. I think i need to tweak that taper just a bit.