Again, I'm just saying a lot of the common "knowledge" that is parroted about simple high carbon steels is wrong (ie 1095 has great edge retention and toughness....this is absolutely false.....people say it because they don't know any better).

Empirical testing dispells these myths.

I own a lot of 1095, enough 5160 and other spring steels, lots of stainless of most flavors...

I've forged and made knives out of 1080, 5160, 15n20...

Owned and used a lot of INFI, cpm3v, 52100, A2, cpm154, 440c, 420hc, 4116 Krupp, Aus8a, Vg10, Vg1, AEBL, 1070, 1055, 1065, 1084,

5160, 6150, L6, 15n20 and about 20 other steels I'm too lazy to look up.

I'm saying that 4034, based on its carbon content and manufacturer should have small carbide, and high toughness.....CS is likely to have a some what decent best treat on the steel. It is not going to blow anyone away with edge retention,

So people shouting it is going to shatter if it chops wood, or cuts a pig are likely incorrect.

Many of the most impressive cuts you see happening with Cold Steel swords is happening with their 1055...an absolutely lowest of the low low carbon steel..... absolutely terrible edge retention....but plenty tough (much more so than 1095, or CarbonV). Their cpm3v knives are dandy, I've owned and used one of their laminated SanMai trailmasters too.

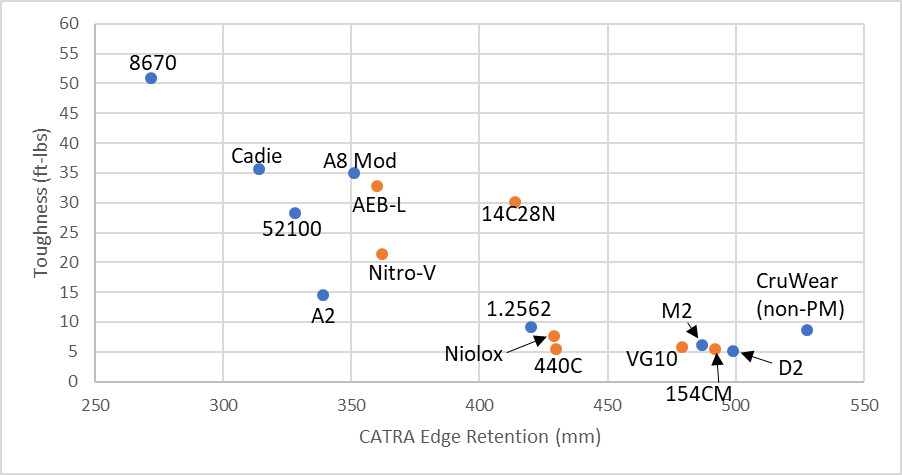

Again I'm not planning on buying one in 4034...I would not have bought it in O1 or A2 either (both are only marginally tougher than 1095 (1095 at about 10 ftlbs toughness pretty low, A2 and 01 are only marginally tougher at 15 ftlbs....1084 can be up at 25 ftlbs, 52100 will get you 30 ftlbs 5160 at 45 ftlbs, Aebl at about 37).

There are man high-end powder metallurgy knife steels. But what about the knife buyer/maker that wants a lower cost option? What's the best choice?

knifesteelnerds.com