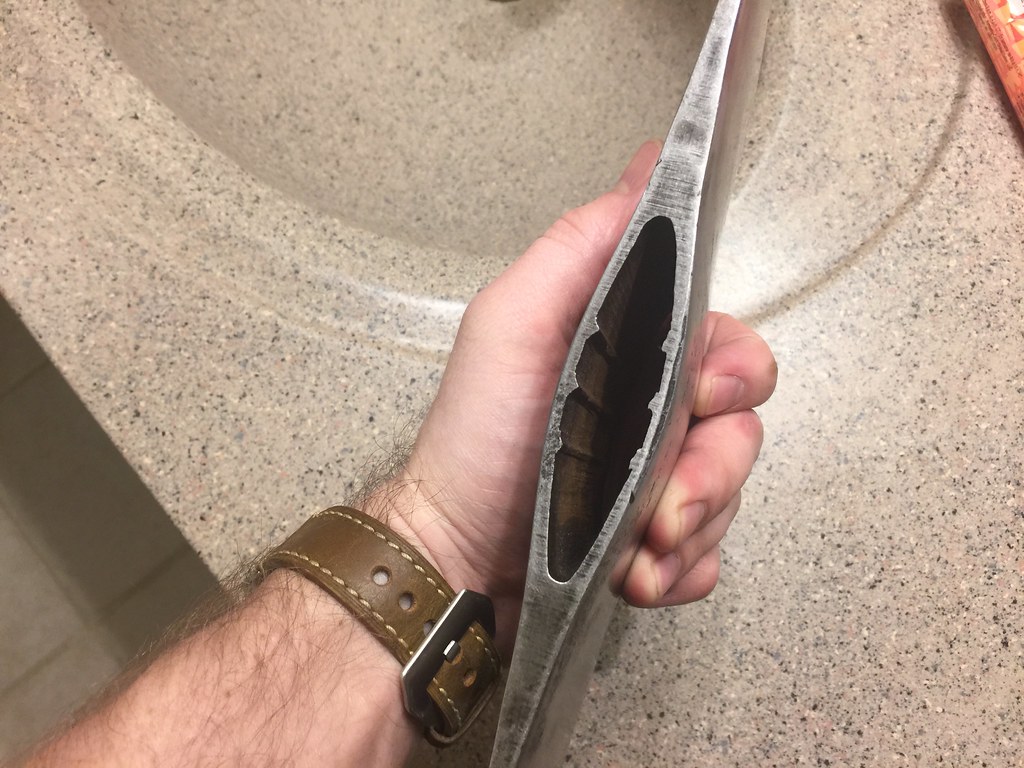

True Temper's patent for the eye ridges was Patent Number 3090653, filed 7/2/59 and granted 5/21/63.... The information previously posted shows that the

True Temper ridges were advertised from 1960 until 1982 (around the time that the Kelly axe factory was shut down). True Temper used the patented ridges on the Kelly Perfect, Woodslasher, and Flint Edge axes. During this period, the Kelly Perfects were evidently stamped and the Woodslasher and Flint Edges had no stamps (just label stickers). So I think

it's likely that unstamped axes with ridges in the eye were originally labelled as Woodslasher or Flint Edge, and made during the period between 1960 and the early 1980s.

The axes with ridges and stamps from other makers, such as Collins or Vaughan, are still a mystery. These known exceptions so far are all stamped, unlike the Woodslasher and Flint Edges from True Temper. Perhaps Barco made some axes with ridges for Vaughan/Collins/Mann after Barco acquired Kelly Axe in 1987?

(Edited to add: YesteryearsTools says that

"Some other brands previously used by other companies [in addition to Kelly] have reportedly been made by Barco but that has not been corroborated nor is the extent of the brand use been determined." )

http://www.yesteryearstools.com/Yesteryears%20Tools/Barco%20Industries.html

I would assume that the ridged eyes weren't manufactured before 1960, since the ad said the feature was new that year, and the patent was ultimately granted to Kelly (which generally wouldn't happen if other companies had been already making them)....