qmether

Gold Member

- Joined

- Jan 27, 2017

- Messages

- 707

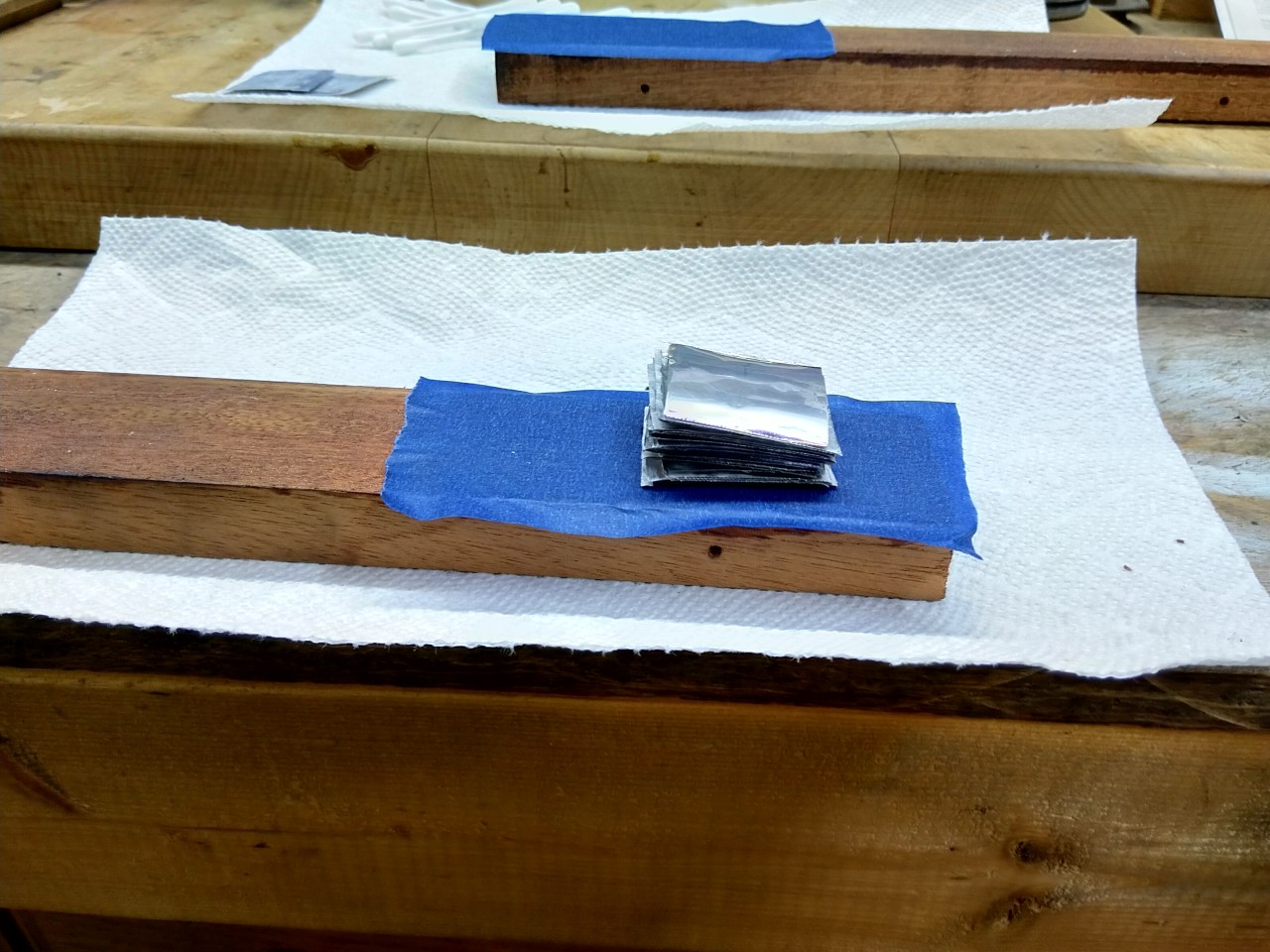

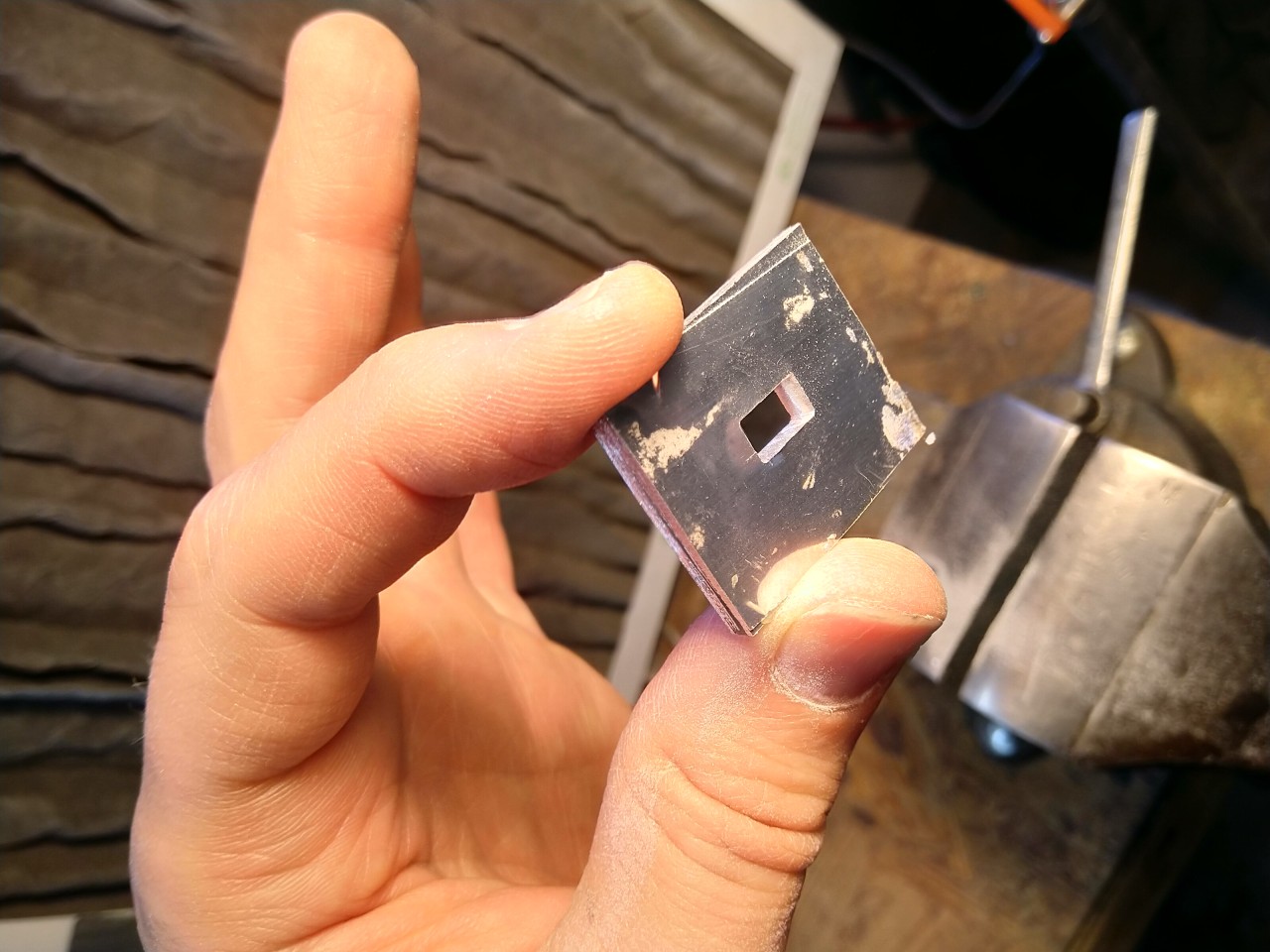

Wow! Looks like I'm in the market for a second BK-16. Is the tip original, or dropped?knife I was fussing with last week. Decided to give it a clip-point. I’m really happy with how it feels in the hand now. The blade itself looked pretty warped after stripping, so most of my time was spent filing and honing the blade flat, and getting rid of that uneven secondary bevel. This one had the worst bevel of three. Slices paper beautifully now. Everything took so much longer than it should have because I really didn’t know what I was doing. First attempt. So many mistakes and dead ends. The white liner is .060” Kydex, and I just used SuperGlue to fix it to the handle scales. I’m finished with it for now.