daizee

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 30, 2009

- Messages

- 11,158

How difficult was it burying that tang into the existing handle?

Marking, drilling, clean up, etc with the existing curves of the handle I imagine is tricky

*lol*

yes, yes it was.

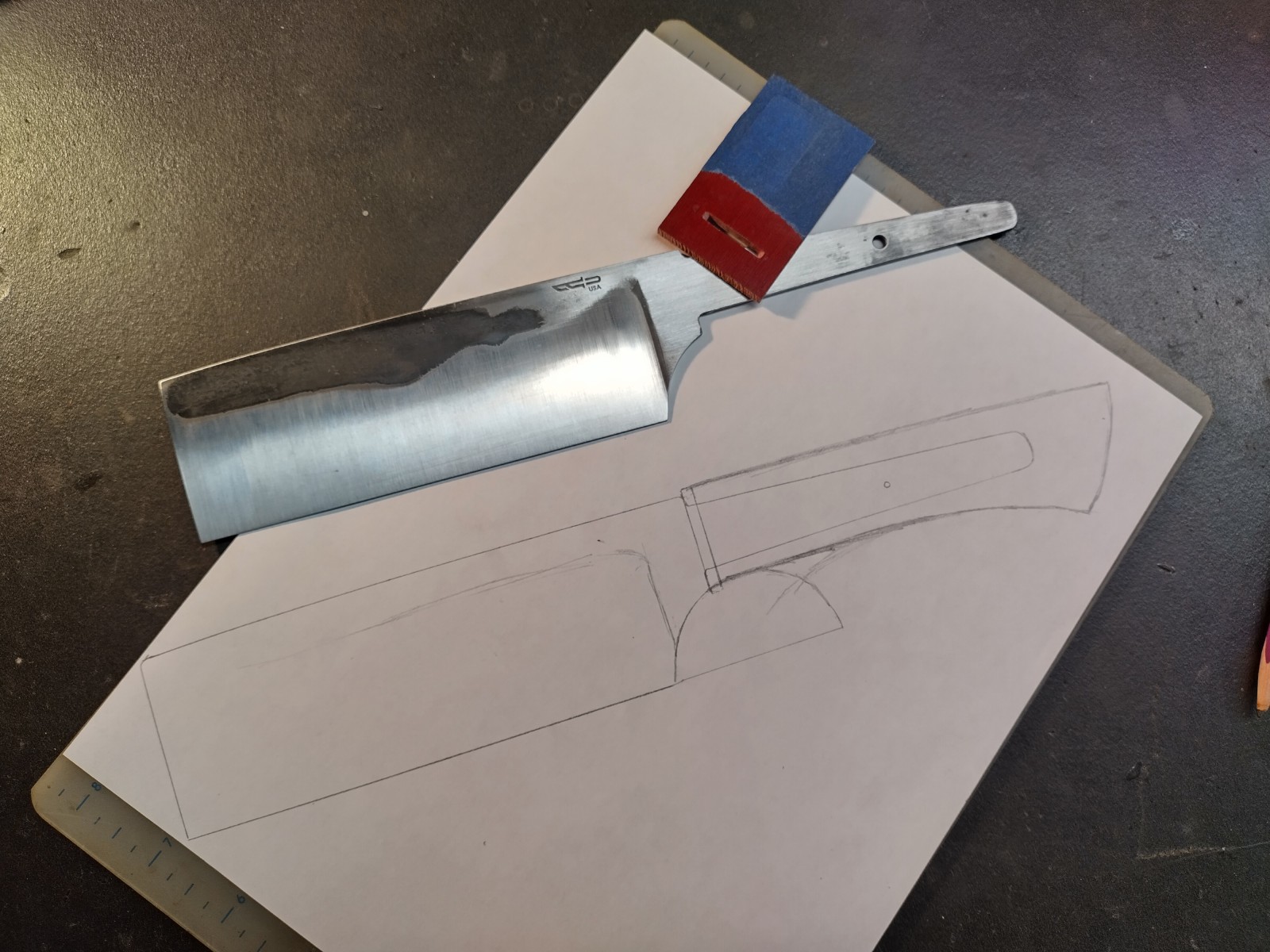

And that tang is 4.25" long, so it's IN there.

When I got to that point I remembered what a pain it was the last time...

I drilled a 3/8" hole and then broached top and bottom key slots. Then squared up the face. Good thing I made a longer broach a couple months ago too!

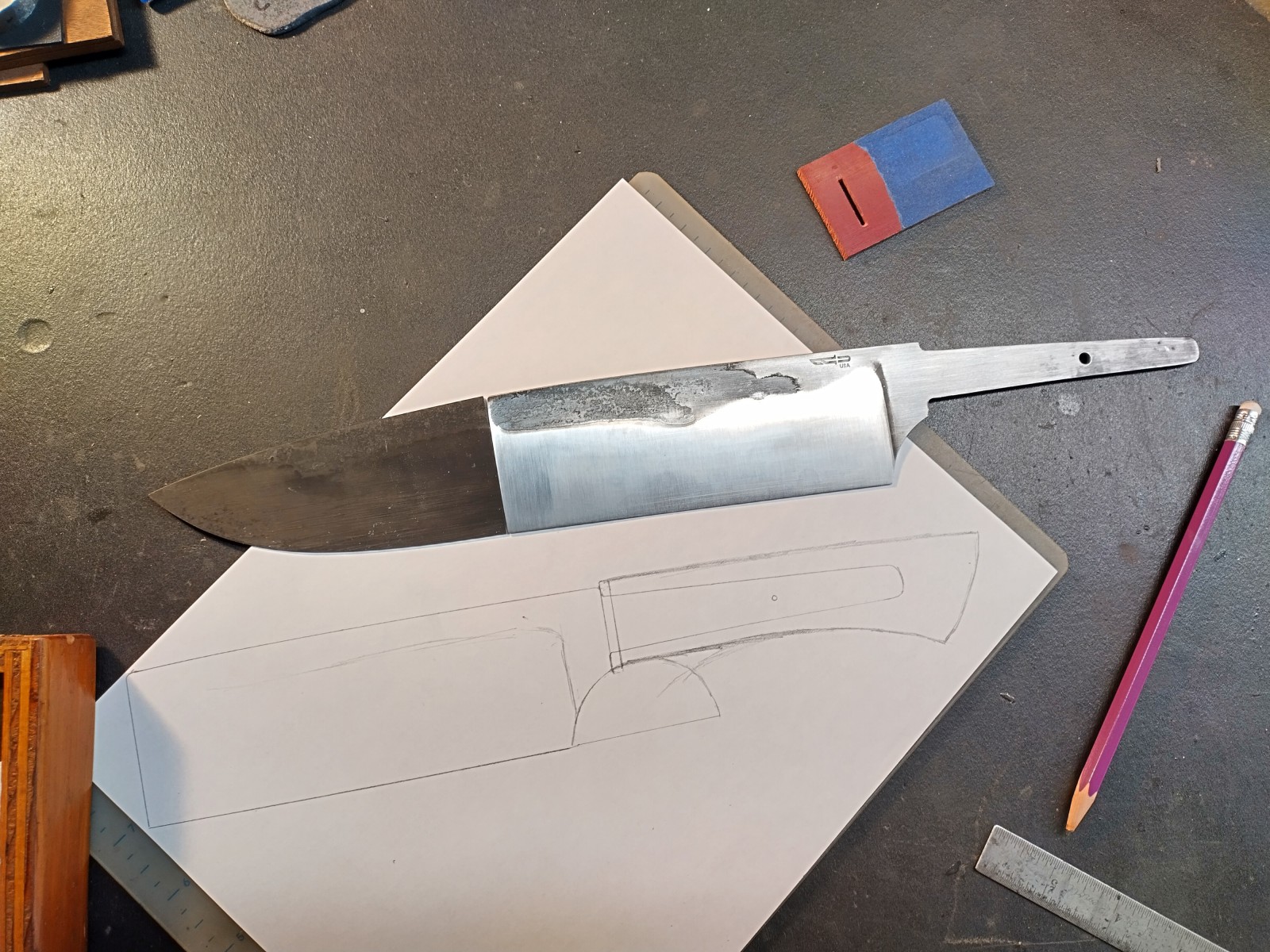

I made a couple clamping wedges with inside curves and used my ubiquitous folded piece of leather as a buffer. It was enough of a trick that I took pictures at the time to remind myself:

I might try shaping the next one, or doing a test handle on some scrap.