hugofeynman

Gold Member

- Joined

- Jan 18, 2011

- Messages

- 1,001

Please try also some high tempered 3v, so we can compare with the low temper ones.I’ll give you a call tomorrow. I’ll send you my address in the morning too. This is much appreciated.

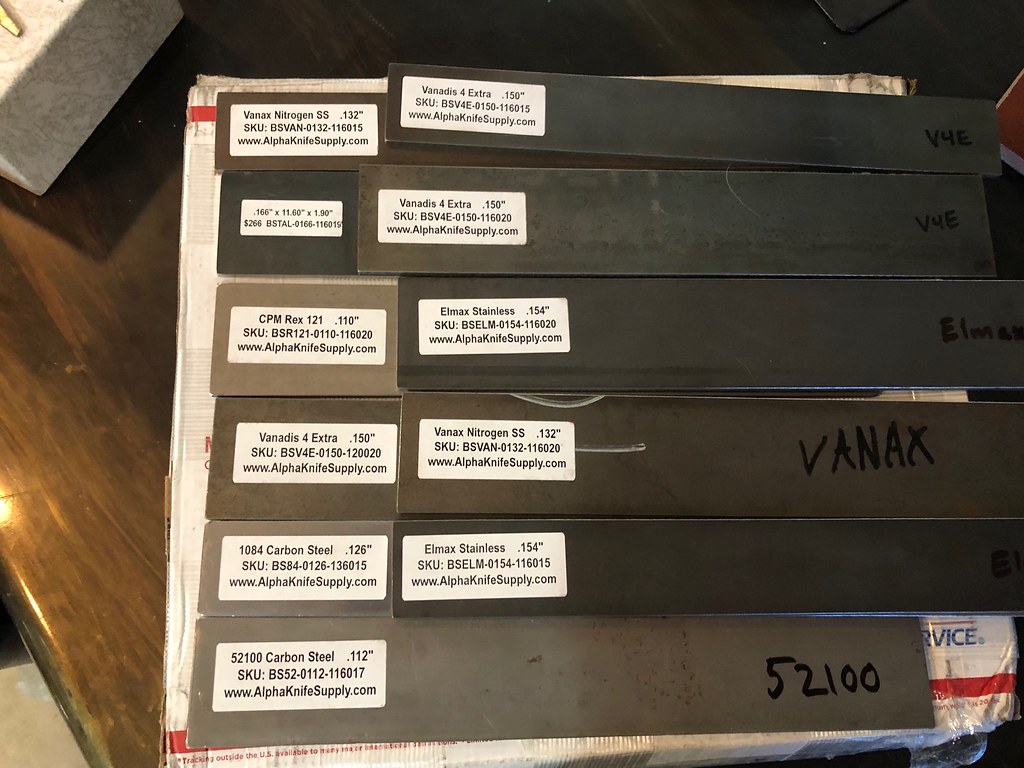

I’m heat treating a bunch of coupons this weekend, so I’ll provide a list for everyone with what’s done and being sent to DevinT,

66721E55-B03C-412A-8124-165C4E8B6A40

66721E55-B03C-412A-8124-165C4E8B6A40