I have to admit, I don't use a Sharpie to check my angles. I only use my naked eye to look for the burr and by feeling for it.

I get tired of the ink coming off into the pores of my stones (the fine ones) .

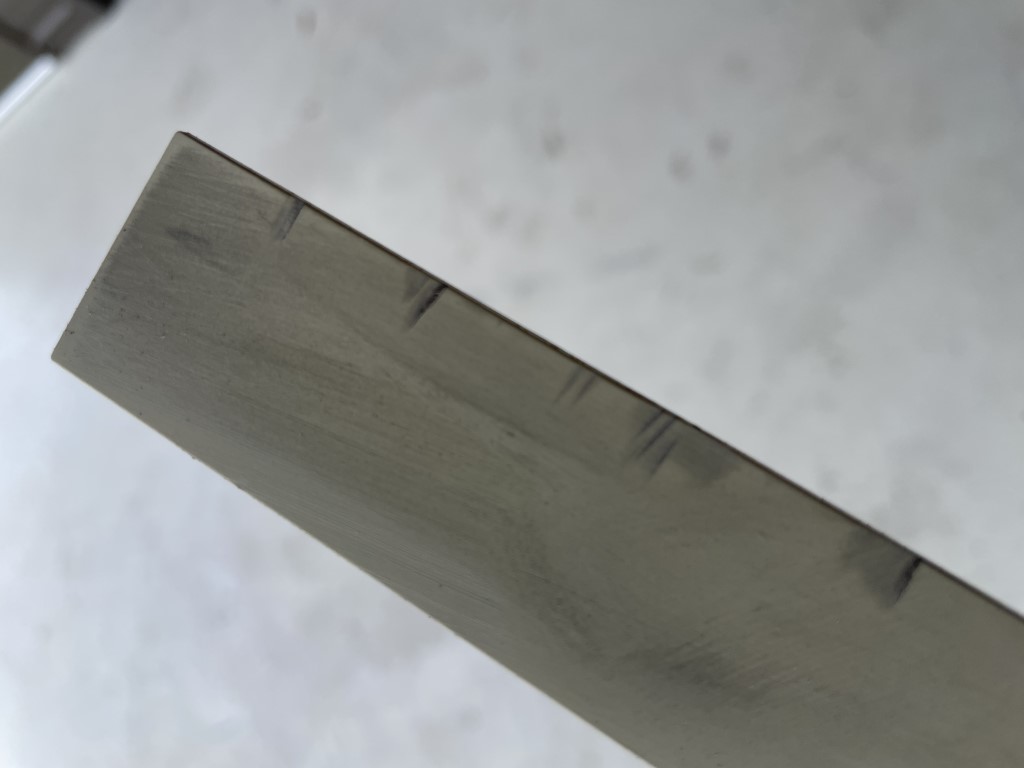

Sharpy ink, in this application is kind of thickish . Personally I cut back on the ink by just putting "ticks" every half inch or 10mm or so down the edge.

One other option is machinist's dye; this tends to be slightly thinner . I put it in nail polish bottles I buy empty on the big river. I have a few stashed around the shops (work and home) .

I also stopped using a light loupe because I didn't want to get too anal about it. Maybe I need to revisit this and go back to it.

As I state in my signature : Good enough is good enough .

but Better "too anal" is Better .

Up to you.

I can sharpen stuff (especially more basic blades like slip joints , box knives , inexpensive kitchen knives ) freehand , without sharpy or lots of light (though I cheat with a jeweller's visor of not too high power Mag 5) and get your basic arm hair shaver .

. . . however . . . and especially for high alloy tool steel (and high alloy stainless on the rare occasion when I feel like whorerlng in that disreputable part of town)

LOTS OF LIGHT on the bench and on the visor

Visor mag 10

A touch of well placed dye

My beloved Edge Pro Apex

The ever so slightest bur reflection of something that is almost not there NOTHING ONE COULD EVER FEEL .

and oooooohhhhh I don't know . . . two swipes per side on the odd denim strop that visits annually with some super fine stropping medium

then two swipes per side on a hard leather finish side strop that , one mad , frivolous night , I introduced to a bottle of 50,000 diamond . . .

WELLLL

THAT

IS BETTER !

call me obsessive

I'm one grinning obsessive .

PS : sharpening my good stuff (and come to think about it my box knife blades ) as I do . . . carefully and to a absolute minimum necessary . . . mostly on very fine grits . . . . I have to marvel and giggle to think people actually

wear out blades just from edge touch ups . I can't imagine ; heck I use the same box knife blade for YEARS ! And then only wind of retiring it because I have found a higher alloy box knife blade or buy an etched one .

( Unboxing machines is part of my weekly tasks at work )

Edit to add " Visor Mag 10 for Better sharpening " .