-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Bears' Den--Shirogorov Showcase

- Thread starter ChazzyP

- Start date

rockman0

Gold Member

- Joined

- May 5, 2013

- Messages

- 3,169

I've been shopping for a new modern knife for several months. I sold my modern customs 7 or 8 years ago as I was more into vintage slip joints. Now that I have a big a$$ pile of awesome old slip joints I'm gravitating back to modern. As you know, there's an overwhelming amount of options. I've narrowed down my choices to a Skiff fugitive, which I missed the drop on a couple weeks ago, or a more obtainable production Shiro F95 zero or the Hati. Both sitting on R1 temping me to pull the trigger. Taking a Shiro apart to clean the factory grease out is a little scary to me as I was struggling to swap pocket clips on a Spyderco military just recently, those tiny little screws were frustrating at best. Is there a special tool to take a Shiro apart? Looks like a screw driver would be a good way to scratch it up badly. Does the flipping action drastically improve with cleaning the factory grease out? Or will the difference be barely noticeable? Based on the reviews I've watched they appear to flip great right out of the box.

Thanks in advance for any comments

Thanks in advance for any comments

I have both of them and Hati is "a step behind" in terms of blade shape. It was the 1st production model to incorporate a long-awaited CPS (Captured Pivot System) feature -- but for the pivot only, the rear screw is not captured unlike it is on newer models. Hati might be updated later this year or in 2025.... or a more obtainable production Shiro F95 zero or the Hati. Both sitting on R1 temping me to pull the trigger.

If I had to choose one to buy soon -- I'd prefer Zero 2024. It's laconic, but not boring and up to date. But your preferences and priorities may vary

Disassembling is not your only option -- a plenty of dish soap and hot water might be enough for cleaning, just make sure to dry it thoroughly (using air compressor for instance).Taking a Shiro apart to clean the factory grease out is a little scary to me

Yes, but it's rather expensive ($300+). Or you could make your own bits from an old brass key or any other piece of soft metal of appropriate shape. Or use a folded plastic card as an expendable tool.Is there a special tool to take a Shiro apart?

Last edited:

Ilikesharpstuff

Basic Member

- Joined

- Jan 19, 2009

- Messages

- 958

I've been shopping for a new modern knife for several months. I sold my modern customs 7 or 8 years ago as I was more into vintage slip joints. Now that I have a big a$$ pile of awesome old slip joints I'm gravitating back to modern. As you know, there's an overwhelming amount of options. I've narrowed down my choices to a Skiff fugitive, which I missed the drop on a couple weeks ago, or a more obtainable production Shiro F95 zero or the Hati. Both sitting on R1 temping me to pull the trigger. Taking a Shiro apart to clean the factory grease out is a little scary to me as I was struggling to swap pocket clips on a Spyderco military just recently, those tiny little screws were frustrating at best. Is there a special tool to take a Shiro apart? Looks like a screw driver would be a good way to scratch it up badly. Does the flipping action drastically improve with cleaning the factory grease out? Or will the difference be barely noticeable? Based on the reviews I've watched they appear to flip great right out of the box.

Thanks in advance for any comments

Not trying to discourage you because Shiros are awesome, but if you're struggling with Spyderco clip screws, Shiro bearings are going to be a nightmare for you. The balls are not captured. Once you get the screws out, you have in the ballpark of 30 tiny (1.5mm) balls to keep track of, clean, lubricate, and drop back into place. Don't get me wrong, I wouldn't call it hard, but it requires extreme care and if vision/dexterity causes you to struggle with clip screws it might be quite the challenge.

rockman0

Gold Member

- Joined

- May 5, 2013

- Messages

- 3,169

Thank you! I appreciate the informationI have both of them and Hati is "a step behind" in terms of blade shape. It was the 1st production model to incorporate a long-awaited CPS (Captured Pivot System) feature -- but for the pivot only, the rear screw is not captured unlike it is on newer models. Hati might be updated later this year or in 2025.

If I had to choose one to buy soon -- I'd prefer Zero 2024. It's laconic, but not boring and up to date. But your preferences and priorities may vary

Disassembling is not your only option -- a plenty of dish soap and hot water might be enough for cleaning, just make sure to dry it thoroughly (using air compressor for instance).

Yes, but it's rather expensive ($300+). Or you could make your own bits from an old brass key or any other piece of soft metal of appropriate shape. Or use a folded plastic card as an expendable tool.

rockman0

Gold Member

- Joined

- May 5, 2013

- Messages

- 3,169

Thank you! I appreciate the advice

Not trying to discourage you because Shiros are awesome, but if you're struggling with Spyderco clip screws, Shiro bearings are going to be a nightmare for you. The balls are not captured. Once you get the screws out, you have in the ballpark of 30 tiny (1.5mm) balls to keep track of, clean, lubricate, and drop back into place. Don't get me wrong, I wouldn't call it hard, but it requires extreme care and if vision/dexterity causes you to struggle with clip screws it might be quite the challenge.

ChazzyP

Platinum Member

- Joined

- Dec 27, 2014

- Messages

- 8,637

The Shiro F95 and Hati are both great knives and would be excellent choices. My two of the former (bought new and newish) and one latter (used, in tough shape) are older models. None of my (currently 8) Shiros were drop shut when acquired--only my since-sold Quantum Ursus NL was. Since being tuned up and breaking in, my re-lubed F95's, 111, and NeOn all drop shut, my F3 is close, the Tabargan with sliding bar lock doesn't count, and the Hati on washers and Russian Dr Death do not. However, all those knives have much freer and quicker flipping action after getting the grease out, though none but the Hati were anything but fine to begin with. Those here with newer Gen knives could speak better regarding their action out of the box.

As to tools, Shiro makes both pen and dedicated driver tools which cost as much as a high quality knife, Josh at REK makes dedicated Shiro bits, and Bill at Jekyll to Hyde makes a nice aluminum tool. I have the JtoH tool and a modest Shiro "Hedgehog" tool which I believe is no longer in production. Frankly, well-fitting coins work just fine on a Shiro's PacMan screws and I frequently use an appropriately-sized common screwdriver bit shrouded with electrical tape.

Dis- and re-assembling a Shiro takes a bit of patience and care. The part that most complainers cite is dealing with the loose bearings, both ball and roller, which run in open-sided cages. One needs to exercise care when removing and replacing those and to protect them while working on the knife. I work on a towel and have a small condiment dish (like from a Chinese restaurant) that I pour alcohol into and drop the bearings, cages, and underlay washers into for both cleaning and safe-keeping. I handle all those parts with a lightly sprung, nylon-tipped tweezer to avoid over-gripping and having a bearing shoot across the room. I avoid any magnetic tools so the bearings don't pick up a charge, complicating getting them back into place.

I don't mean to make this sound too daunting--just laying it out for you. I actually enjoy the fineness and finesse of the work and consider it good training/therapy for the diminished vision and progression of my essential tremor that have accompanied my advancing years.

rockman0

Gold Member

- Joined

- May 5, 2013

- Messages

- 3,169

Leo Greer

Gold Member

- Joined

- Dec 30, 2021

- Messages

- 891

Thanks for the extra info, it is surprising indeed.

But are you sure that your Quantum Ursus was made in 2019?

According to the maker's website an affordable series of Quantum model was announced on 2021-12-09 as Quantum Ursus and it was offered with wood inlays only (hence NL suffix) at first, G10 versions appeared a few months later.

I wonder if your knife is a special edition, made for specific US dealer with exclusive pattern on the scales.

The 1st generation of production Quantum did have a ramp, according to the photo from the official announcement (dated 2020-03-21) -- probably it is the 1st production model (top-tier, but nonetheless) to incorporate the feature:

I was mistaken on the COA date—I checked and it’s 2022, not sure why I thought it was 2019.

I use a work sharp pro, and im very pleased with the results. But i dont pretend im a good freehand sharpener (im not.. at all).Congrats on the new Bear--I like my fullered M390 111 CF a lot. Most of my Shiro's have come through really close to 20° per side but the 111 came through brand new at around 22-23° which rather displeased me for cutting ability.

I decided after a while to re-profile on the other side of 20 and went with an edge in the 17-18° range. I did that on my EdgePro before I had my diamond Matrix stones and it took a while to get what I wanted on its M390, but it came out very nicely and became a much scarier sharp cutter. It's definitely broader than your typical ultra-narrow Shiro edge, but their blades are so thin BTE that it's not objectionable to these eyes.

I didn't remember if I put a 20° micro-bevel on it or not so I just got it out to check. No micro-bevel and I notice it's developed a little burr in a couple areas and is very slightly chippy in others, though still pretty damn sharp for not being attended to for some time. A few swipes on the fines and ultra-fines at 20° in the morning will add just a taste of micro-bevel and straighten things right out.

Putting a Shiro on a Work Sharp? You're a braver man than I, but maybe you're just real good with that device.

Any chance i can get a link to the bushings? I love my little machine, but i want badly to up my game on it. Ive looked for upgrades for it, and not finding muchI really need to break out my newer WorkSharp Professional (upgrade from precision adjust), install the new brass bushings on the slider, and give it a whirl.

- Joined

- Oct 3, 2011

- Messages

- 5,451

I have both of them and Hati is "a step behind" in terms of blade shape. It was the 1st production model to incorporate a long-awaited CPS (Captured Pivot System) feature -- but for the pivot only, the rear screw is not captured unlike it is on newer models. Hati might be updated later this year or in 2025.

If I had to choose one to buy soon -- I'd prefer Zero 2024. It's laconic, but not boring and up to date. But your preferences and priorities may vary

Disassembling is not your only option -- a plenty of dish soap and hot water might be enough for cleaning, just make sure to dry it thoroughly (using air compressor for instance).

Yes, but it's rather expensive ($300+). Or you could make your own bits from an old brass key or any other piece of soft metal of appropriate shape. Or use a folded plastic card as an expendable tool.

rockman0 ,

The Shiro F95 and Hati are both great knives and would be excellent choices. My two of the former (bought new and newish) and one latter (used, in tough shape) are older models. None of my (currently 8) Shiros were drop shut when acquired--only my since-sold Quantum Ursus NL was. Since being tuned up and breaking in, my re-lubed F95's, 111, and NeOn all drop shut, my F3 is close, the Tabargan with sliding bar lock doesn't count, and the Hati on washers and Russian Dr Death do not. However, all those knives have much freer and quicker flipping action after getting the grease out, though none but the Hati were anything but fine to begin with. Those here with newer Gen knives could speak better regarding their action out of the box.

As to tools, Shiro makes both pen and dedicated driver tools which cost as much as a high quality knife, Josh at REK makes dedicated Shiro bits, and Bill at Jekyll to Hyde makes a nice aluminum tool. I have the JtoH tool and a modest Shiro "Hedgehog" tool which I believe is no longer in production. Frankly, well-fitting coins work just fine on a Shiro's PacMan screws and I frequently use an appropriately-sized common screwdriver bit shrouded with electrical tape.

Dis- and re-assembling a Shiro takes a bit of patience and care. The part that most complainers cite is dealing with the loose bearings, both ball and roller, which run in open-sided cages. One needs to exercise care when removing and replacing those and to protect them while working on the knife. I work on a towel and have a small condiment dish (like from a Chinese restaurant) that I pour alcohol into and drop the bearings, cages, and underlay washers into for both cleaning and safe-keeping. I handle all those parts with a lightly sprung, nylon-tipped tweezer to avoid over-gripping and having a bearing shoot across the room. I avoid any magnetic tools so the bearings don't pick up a charge, complicating getting them back into place.

I don't mean to make this sound too daunting--just laying it out for you. I actually enjoy the fineness and finesse of the work and consider it good training/therapy for the diminished vision and progression of my essential tremor that have accompanied my advancing years.

ChazzyP Thank you for the detailed explanation of cleaning. That helps. My biggest struggle with the Spyderco was i didn't have a magnetic tip to steady the screws, I was putting on a Lynch NW deep carry clip and trying to guide the screw through the clip's hole to access the top screw hole was a challenge. With the nylon tweezers I think I can manage the bearings just fine. I'm 66 and retired, my hands are steady but my vision isn't what it used to be. At worst I'll need borrow my wife's magnifier for her knitting projects. I can devise my own non scratch tools base on your suggestions

Any chance i can get a link to the bushings? I love my little machine, but i want badly to up my game on it. Ive looked for upgrades for it, and not finding much

Like he said above "I frequently use an appropriately-sized common screwdriver bit shrouded with electrical tape" is what I do, without buying a fancy soft screwdriver bit.

For the bushings I went to the Yuge! online sales website and bought thew following item, as recommended by "Cutting Board Reviews aka CBRx" on YouTube.

"10Pcs Sleeve Bearings 1/4" Bore, 2/5"OD, 2/5"Length, Cast Brass Self-Lubricating Bushings(6mm Bore x 10mm OD x 10mm Length)"

New knife day x2, and an updated collection pic! I have another lee kickstop in the mail too.

- Joined

- Oct 3, 2011

- Messages

- 5,451

New knife day x2, and an updated collection pic! I have another lee kickstop in the mail too.

Fixed it for you

- Joined

- Dec 24, 2017

- Messages

- 226

Meanwhile there's something to hunt tomorrow...Here's a teaser from social media, posted by the maker with the following comment:

"Very soon (at 1pm PST tomorrow for our international collectors, to be exact)"

I really hope it's Astrum FP.

Oh, yeah!.. I desperately want one as an EDC -- a 100×3 mm MagnaCut blade might be very interesting. The scales texturing is relatively simpler (compared to Astrum CD), but obviously more grippy than production Stellar.

Shame they seem to have gotten days confused or something came up and no announcement. Definitely does SEEM like it's going to be production Astrum given the milling teaser previously. I am very onboard for a first production/sprint run type situation for one. I've been after a CD/SR but would love to be able to save a bit of cash and keep that toward a CDX, while still adding an Astrum.

Hulk2e

Gold Member

- Joined

- Dec 18, 2014

- Messages

- 985

Holy smokes!! That’s one hell of a collection.Fixed it for you

I've almost sent a comment regarding your Elementary F3 set hidden in the safe and not presented on the picture, but stopped in the last second.

Shame they seem to have gotten days confused or something came up and no announcement.

Well, the message was published a few hours earlier than it should be -- at 9:00am MSK (UTC+3:00, Friday), i.e. 10:00pm PST (UTC-8:00, Thursday), but they definitely meant "expect the drop at 1pm PST, Saturday".

There's a pattern -- "Soon" teaser on Thursday, "Really soon" teaser on Friday and the actual drop on Saturday.

I don't know why they used PST and not PT:

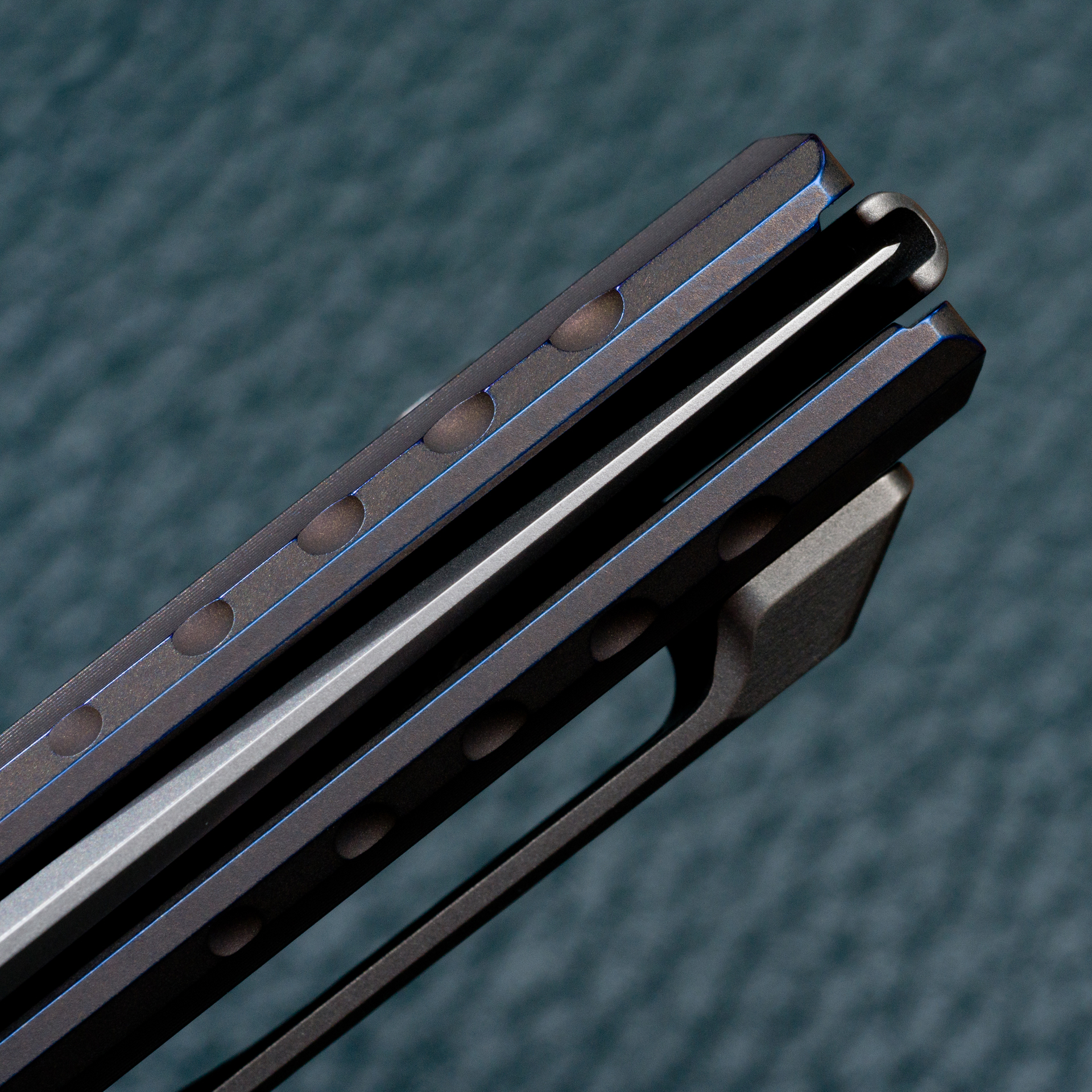

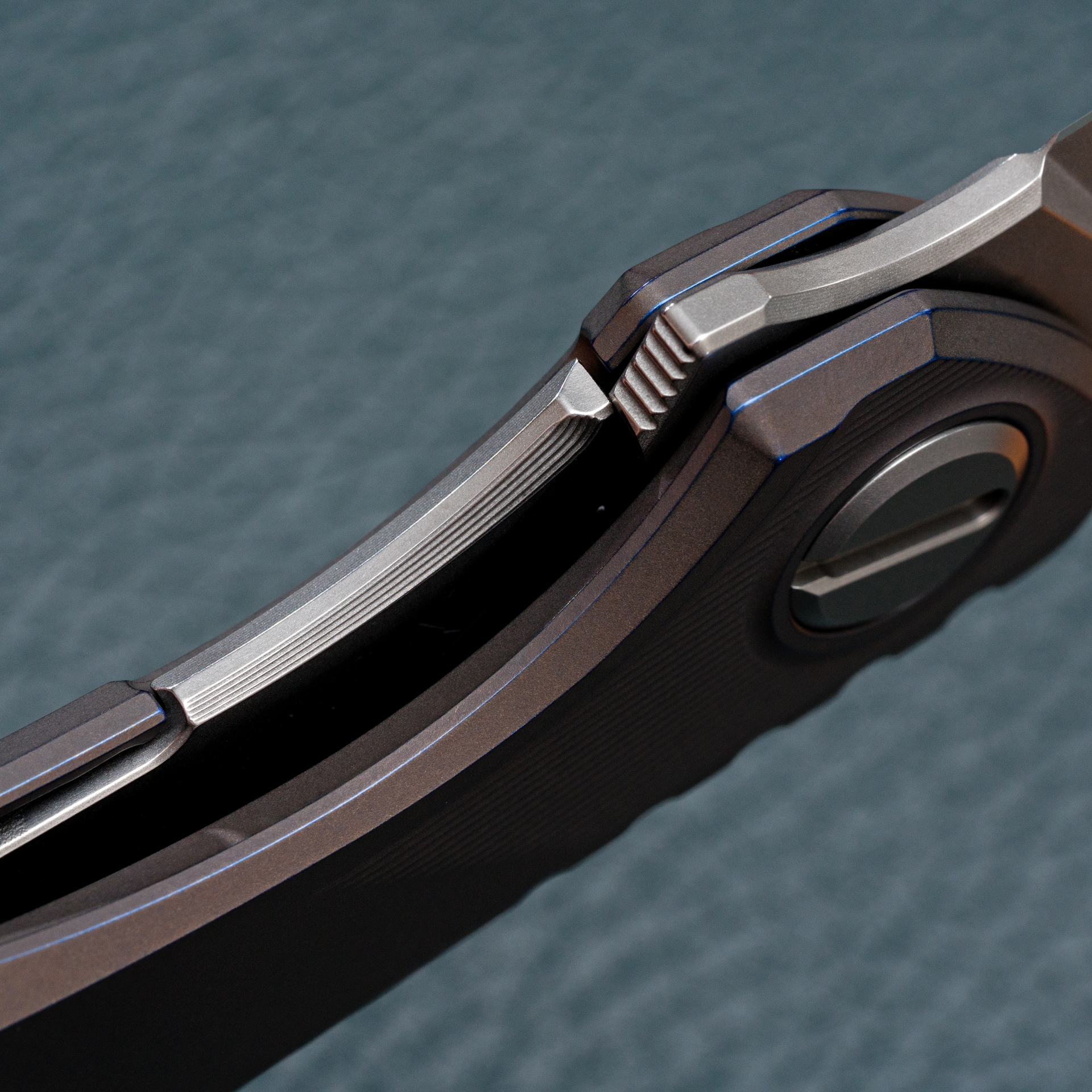

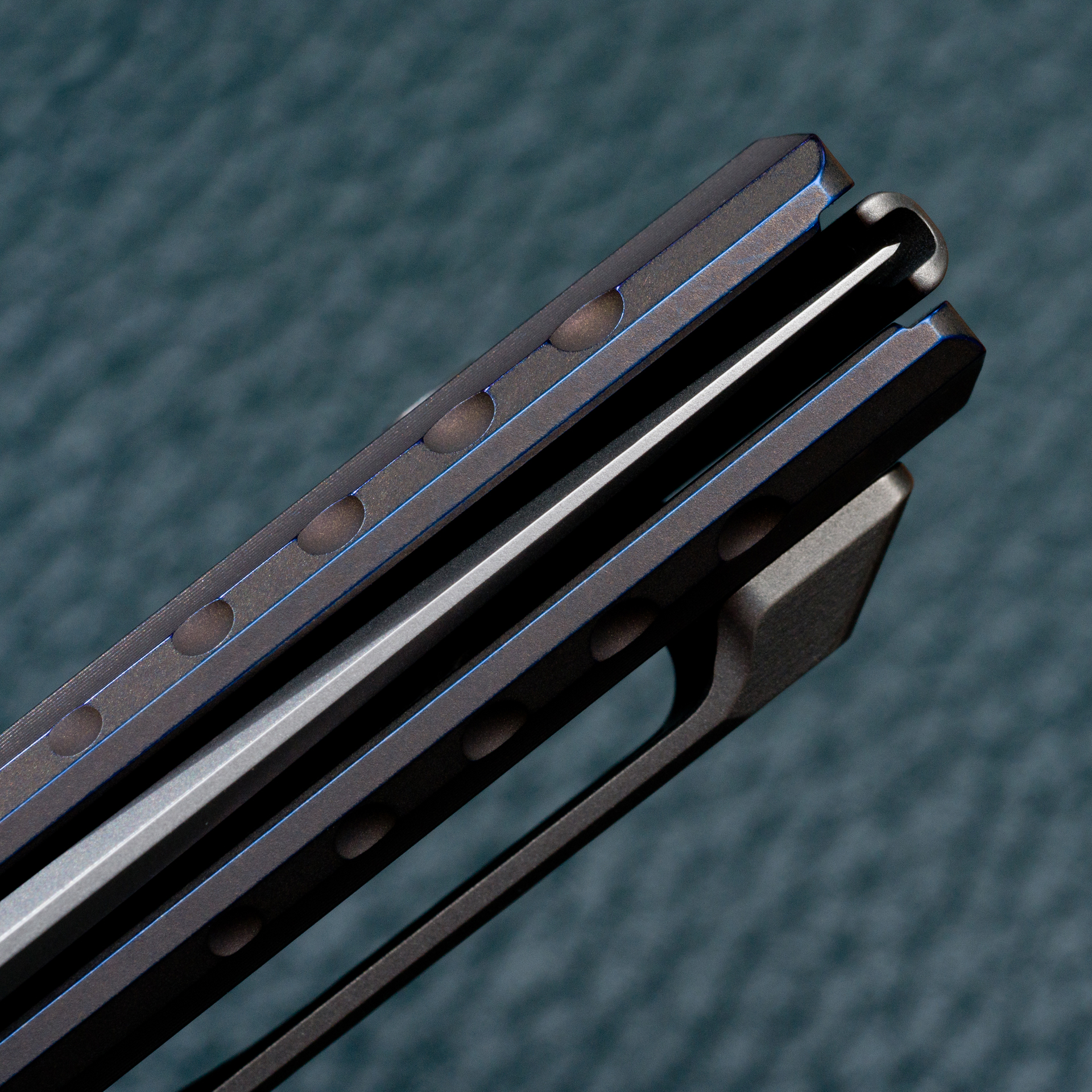

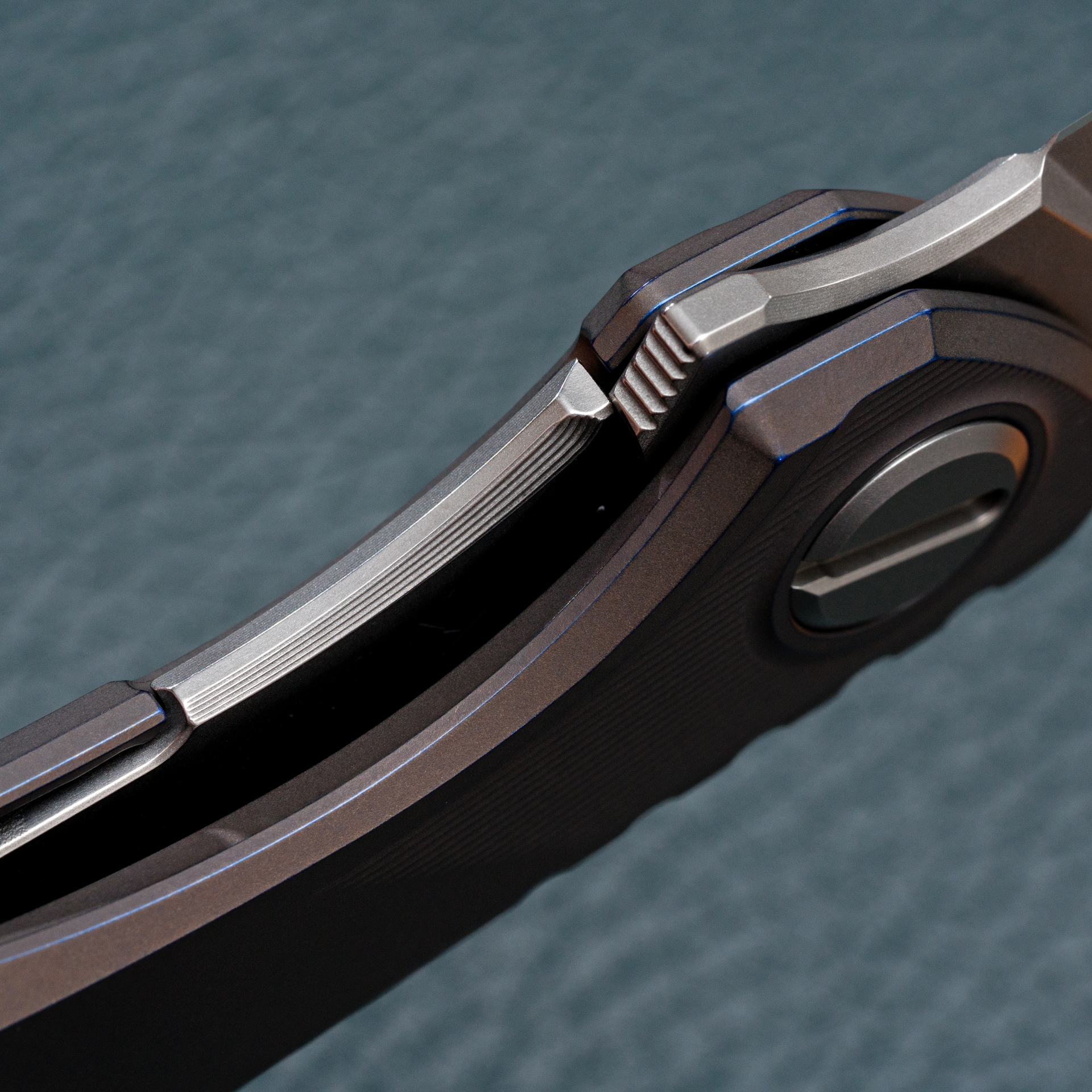

That fine, fluted milling on the blade choil chamfers is interesting, though somewhat curious. I can't think of any practical reason for its inclusion, such as traction, as one can't get a finger in there to choke up on the handle as the Zero's choil looks quite the same size as those on my F95R and TurtIe. I don't know that it provides anything much aesthetically either, though it does somewhat echo the fine milling on the handle slabs.

I guess that milling is a feature one may describe as "we made it just because we can, not because you need it for any practical reason"

After all, the updated F95 Zero is based on F95 NL Gen 5, which has milling on the inner side of lanyard cavities, concealed from the observation -- especially with a lanyard attached. I don't have one at hand, so here's the picture from the maker:

Last edited:

Phew.. I managed to snatch one!..

The good news -- you may expect ~50 knives for the US market.

The bad news -- table price might be somewhere between production and CD. At least in Russia it was 27% more expensive than production Stellar.

But if you want a 100mm Shiro slicer in MagnaCut, I believe it's worth the money.

Good luck to anyone interested in this long, slim and lightweight FP.

P.S. I checked -- there's milling on the blade choil chamfers, as expected for recent CD and limited editions:

The good news -- you may expect ~50 knives for the US market.

The bad news -- table price might be somewhere between production and CD. At least in Russia it was 27% more expensive than production Stellar.

But if you want a 100mm Shiro slicer in MagnaCut, I believe it's worth the money.

Good luck to anyone interested in this long, slim and lightweight FP.

P.S. I checked -- there's milling on the blade choil chamfers, as expected for recent CD and limited editions:

Last edited:

- Joined

- Dec 24, 2017

- Messages

- 226

Phew.. I managed to snatch one!..

The good news -- you may expect ~50 knives for the US market.

The bad news -- table price might be somewhere between production and CD. At least in Russia it was 27% more expensive than production Stellar.

But if you want a 100mm Shiro slicer in MagnaCut, I believe it's worth the money.

Good luck to everyony interested in this long and slim FP.

Thanks for all the information! Just went up and I was able to snag one for myself. Looking forward to it - really appreciate the incredible pictures. All the milling on these limited production serials is getting pretty extreme - love to see it.