Hickory n steel

Gold Member

- Joined

- Feb 11, 2016

- Messages

- 21,053

I won't lie the second cross wedge piece isn't really in there much at all, but it really didn't need them and I only put them in there because I already had the kerf cut ( not as deep as the main wedges' kerf ) and was pretty much committed at that point.

I think if I had bothered to read up on agent H's thread about cross wedging I probably could have done a better job with the cross wedging.

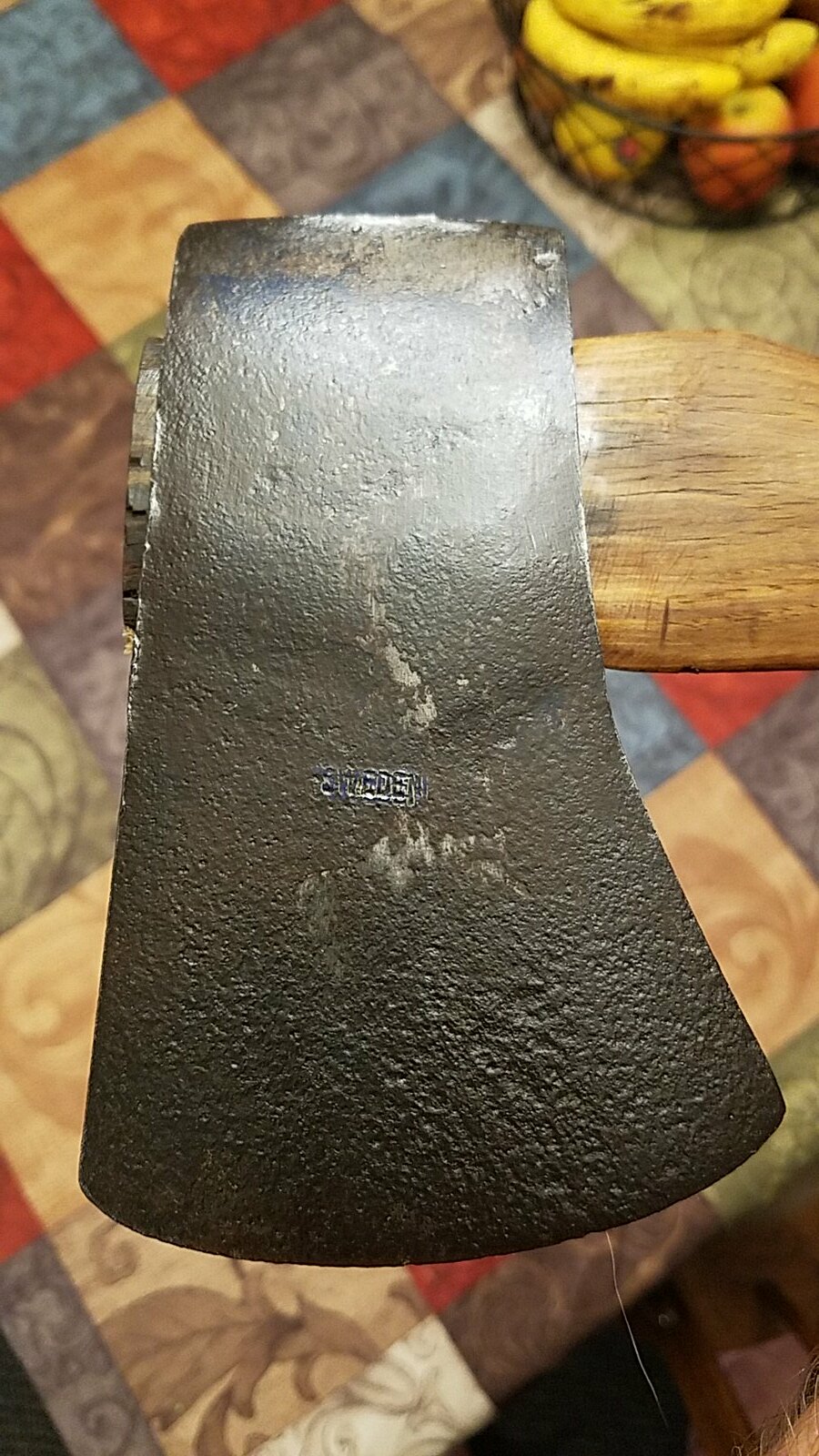

IMG_20170821_232712

IMG_20170821_232712 IMG_20170821_232904

IMG_20170821_232904 IMG_20170821_232737

IMG_20170821_232737 IMG_20170821_232807

IMG_20170821_232807 IMG_20170821_232851

IMG_20170821_232851 PikeStreet

PikeStreet PikeStreet

PikeStreet IMG_20170822_125040

IMG_20170822_125040 IMG_20170822_125025

IMG_20170822_125025 IMG_20170822_124925

IMG_20170822_124925 IMG_20170822_124933

IMG_20170822_124933 IMG_20170822_124939

IMG_20170822_124939