I like it ! Manual CNC . . .Here is a jig I cobbled together to mill the reliefs in liners of slip joints

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop? Show us whats going on, and talk a bit about your work!

- Thread starter WillSwift

- Start date

I like them all , but I don t like all that hole .....I would never drill hole in tang in front of first pin , for a few grams of relief they weaken tang to much in critical point ?Trying to jump into this knife making thing full force, these (and a few more) are getting heat treated Friday morning. The bottom 2 are O1 & the rest are 1095.

My first knife was a big ugly chopper thing in O1 a few years ago. This is my first real effort at trying to make some more practical knife shaped objects, so it's mostly experimental to see how the material behaves & what I can get away with.

There is no way I could have done this without the wealth of information other makers have shared here - so THANK YOU to everyone who helps and contributes!!!!

Last edited:

- Joined

- Apr 13, 2017

- Messages

- 2,174

ashwinearl

Knifemaker / Craftsman / Service Provider

- Joined

- Nov 9, 2006

- Messages

- 556

3" blade "drop-puk" in 15N20 Ruby G10 work in progress. I tried to get a clay hamon but got no action so went to satin finish. 320g off the grinder on the handle now to some hand sanding and cleaning the spine

ashwinearl

Knifemaker / Craftsman / Service Provider

- Joined

- Nov 9, 2006

- Messages

- 556

Another drop-puk to go with that burgundy in orange G10 to match my college colors. This one is rougher with acid etched/stone tumble finish and textured G10 handle.

On both these, I think I took too much off the front of the handle/put the pin too close to the front. I'll rethink the pin design next time.

On both these, I think I took too much off the front of the handle/put the pin too close to the front. I'll rethink the pin design next time.

A.McPherson

Knifemaker / Craftsman / Service Provider

- Joined

- Jan 27, 2012

- Messages

- 2,921

- Joined

- Jan 1, 2006

- Messages

- 1,649

Just got this guy done!

Recently finished and sold this one

this one too

and what I thought was a pretty nice kydex sheath

Recently finished and sold this one

this one too

and what I thought was a pretty nice kydex sheath

Last edited:

- Joined

- Mar 28, 2016

- Messages

- 811

West Lake Tactical 5/16"... https://www.amazon.com/dp/B01M5JKHP1?ref=ppx_pop_mob_ap_share

A.McPherson

Knifemaker / Craftsman / Service Provider

- Joined

- Jan 27, 2012

- Messages

- 2,921

Thanks!

- Joined

- Aug 3, 2012

- Messages

- 1,434

I like them all , but I don t like all that hole .....I would never drill hole in tang in front of first pin , for a few grams of relief they weaken tang to much in critical point ?

Interesting - and very good point! I didn't think about that, but definitely will on the next round. The one on the far right, the intent is to put brass bolsters on with 4 brass pins. No idea if it will work or not, this is all learning & experimentation for me.

OccamsBlade

Jim Dobbler

- Joined

- Jan 23, 2014

- Messages

- 227

So here's what I'm working with now for doing spoons n' stuff, to give you guys a visual. I use a humble little 4x4 anvil that I bought from Old World Anvils and a base I made for it. A 4" mushroom stake from Iron Mountain Forge for doing ladles and planishing. And a Holland Swage block, also with a base I made for it and the mushroom stake. That bucket filled with cement and a post sticking out is for mounting my Atlas forge. Works quite nicely.

- Joined

- Feb 27, 2006

- Messages

- 5,191

very cool integral bolsters ! no soldering to mess with

- Joined

- Aug 3, 2012

- Messages

- 1,434

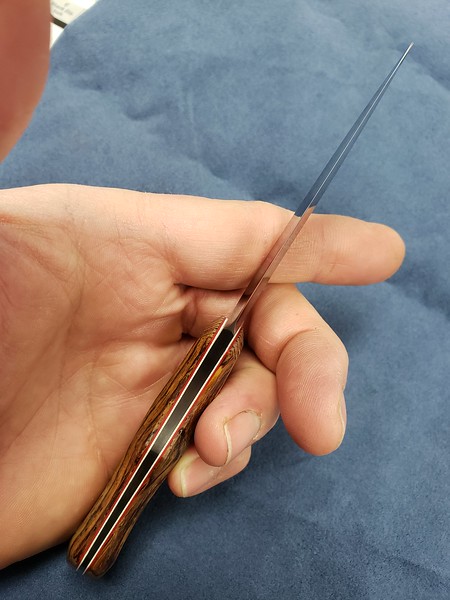

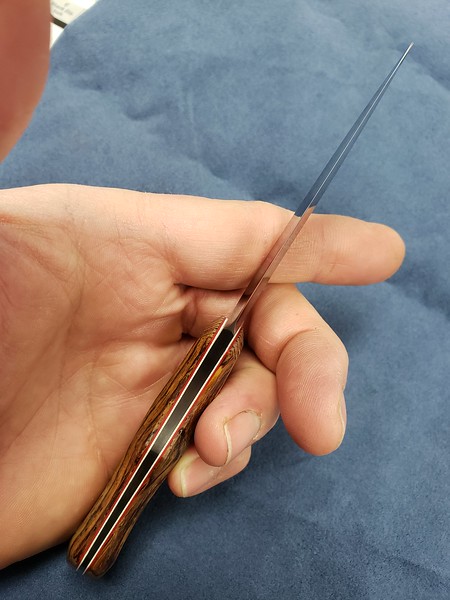

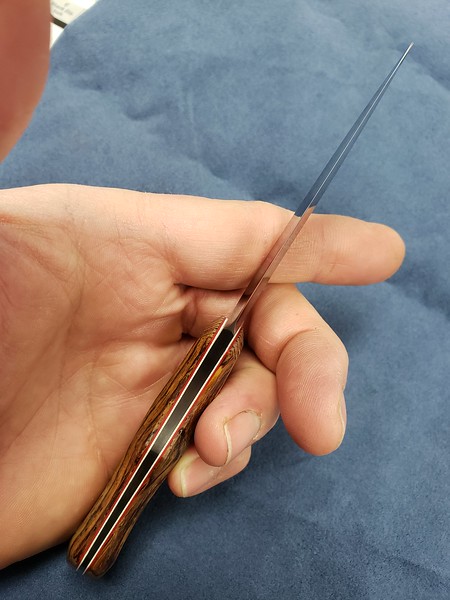

I finally finished a knife!!

Technically, this is #2, but it's definitely my first usable, practical knife. The very first was this one, waaaaaayyy back in 2013: https://www.bladeforums.com/threads/o1-chopper-edit-6-24-finished-pics-added.1080625/

It's 6-1/2" OAL, slightly over 3'' blade, 1095 steel hardened to 61Rc. I hollow ground (10'' wheel) the edge to 0.010/0.008'' before sharpening on paper wheels (10-15° per side, best guess). Shaving sharp is an understatement.

Scales are bocote over red & white liners, stainless pin & lanyard tube.

I learned a lot on this one, made a few mistakes, but overall I'm happy with how it turned out. Hopefully it's not another 6 years for the next one... Comments, critique & suggestions are always welcome. Thanks for looking!

Technically, this is #2, but it's definitely my first usable, practical knife. The very first was this one, waaaaaayyy back in 2013: https://www.bladeforums.com/threads/o1-chopper-edit-6-24-finished-pics-added.1080625/

It's 6-1/2" OAL, slightly over 3'' blade, 1095 steel hardened to 61Rc. I hollow ground (10'' wheel) the edge to 0.010/0.008'' before sharpening on paper wheels (10-15° per side, best guess). Shaving sharp is an understatement.

Scales are bocote over red & white liners, stainless pin & lanyard tube.

I learned a lot on this one, made a few mistakes, but overall I'm happy with how it turned out. Hopefully it's not another 6 years for the next one... Comments, critique & suggestions are always welcome. Thanks for looking!

Richard338

Gold Member

- Joined

- May 3, 2005

- Messages

- 7,481

I finally finished a knife!!

Technically, this is #2, but it's definitely my first usable, practical knife. The very first was this one, waaaaaayyy back in 2013: https://www.bladeforums.com/threads/o1-chopper-edit-6-24-finished-pics-added.1080625/

It's 6-1/2" OAL, slightly over 3'' blade, 1095 steel hardened to 61Rc. I hollow ground (10'' wheel) the edge to 0.010/0.008'' before sharpening on paper wheels (10-15° per side, best guess). Shaving sharp is an understatement.

Scales are bocote over red & white liners, stainless pin & lanyard tube.

I learned a lot on this one, made a few mistakes, but overall I'm happy with how it turned out. Hopefully it's not another 6 years for the next one... Comments, critique & suggestions are always welcome. Thanks for looking!

Nice.

If you are already tapering the tang on your second knife, you are probably ready for a keyhole antler handle on the next one!

Rose and Thistle Custom

Josh Mead

- Joined

- May 9, 2018

- Messages

- 2,301

Wow that is really cool, nice work.

- Joined

- Aug 3, 2012

- Messages

- 1,434

Nice.

If you are already tapering the tang on your second knife, you are probably ready for a keyhole antler handle on the next one!

Ha! If I could figure out HOW a keyhole knife is made, I'd give it a shot!

Tapering the tang was surprisingly easy. Drilling holes in scales through a tapered tang was not - my pin hole ended up a little wonky.

Richard338

Gold Member

- Joined

- May 3, 2005

- Messages

- 7,481

It should be easy... just follow JT's WIP!Ha! If I could figure out HOW a keyhole knife is made, I'd give it a shot!

Tapering the tang was surprisingly easy. Drilling holes in scales through a tapered tang was not - my pin hole ended up a little wonky.

https://www.bladeforums.com/threads/keyhole-antler-bowie-wip.1616834/