-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop? Show us whats going on, and talk a bit about your work!

- Thread starter WillSwift

- Start date

- Joined

- Apr 3, 2011

- Messages

- 5,963

The

You do great work, I hope I didn't come across the wrong way! Of course, I've found that the right belts help a ton otherwise you can get screwed quickI'll get there one day!

- Joined

- Dec 5, 2005

- Messages

- 28,534

thank you, and not at all!The

You do great work, I hope I didn't come across the wrong way! Of course, I've found that the right belts help a ton otherwise you can get screwed quick

Hi everybody!

I want to show you my first kitchen set made for a dear friend!

@Moderator: If the post is not in the rigth area, feel free to delete it!

They are not perfect at ALL but I wil get better. Any suggestion is welcome!

Blades: stainless steel AISI420. 58 HRC

Handles: walnut + white spacers (the smaller one is made whit vineyard wood + brass spacers)

Knife holder: poplar

I want to show you my first kitchen set made for a dear friend!

@Moderator: If the post is not in the rigth area, feel free to delete it!

They are not perfect at ALL but I wil get better. Any suggestion is welcome!

Blades: stainless steel AISI420. 58 HRC

Handles: walnut + white spacers (the smaller one is made whit vineyard wood + brass spacers)

Knife holder: poplar

A.McPherson

Knifemaker / Craftsman / Service Provider

- Joined

- Jan 27, 2012

- Messages

- 2,921

I

Infradito

Nice set!

My advise is to get better at finishing sanding. Your blades have lots of scratches going in lots of different directions. A really nice satin finish will have scratches only in one direction, and all of the same depth. A mirror finish will have no visible scratches at all.

Watch this video by Nick Wheeler, it'll change your whole outlook on what "good" is.

Nice set!

My advise is to get better at finishing sanding. Your blades have lots of scratches going in lots of different directions. A really nice satin finish will have scratches only in one direction, and all of the same depth. A mirror finish will have no visible scratches at all.

Watch this video by Nick Wheeler, it'll change your whole outlook on what "good" is.

- Joined

- Dec 30, 2018

- Messages

- 267

Also looks like TBE could be much thinner looking at how high secondary bevel is. If you don’t have a grinder it can be thinned on some stones.

- Joined

- Jun 3, 2019

- Messages

- 2,714

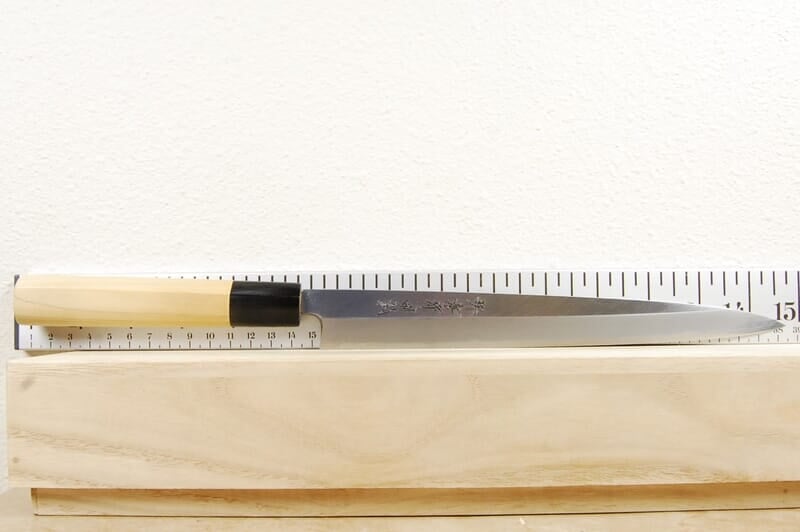

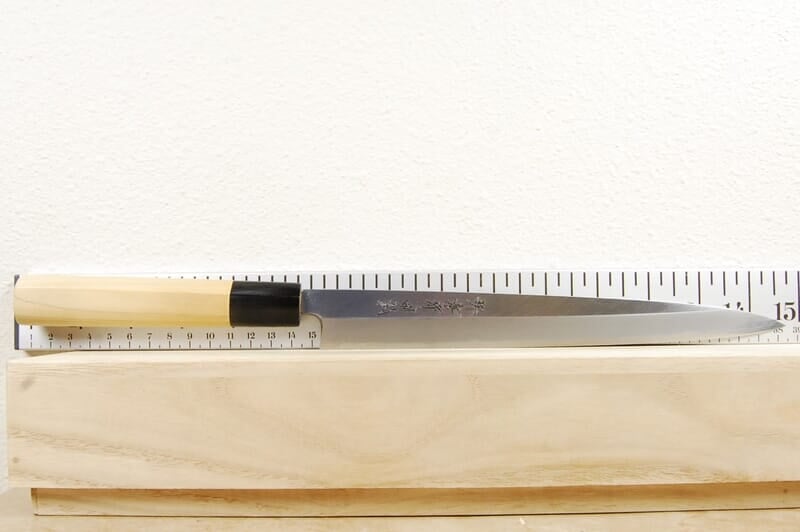

FINALLY had a chance to finish up (mostly) this knife - this one for me. Only took me a year or so :-(. A Yanagabi, 26C3 @ 64 rockwell, 9 inch blade, 0.1350 stock at the spine (which seems thick to me, but every time I check is consistent with the commercial knives I can see out there. Handle is Kingwood with cocobolo butt and bolster, copper spacers (I LIKE Kingwood.....) . Still have a little touch up to do (filling in a couple small gaps in glue at the bolster/ricasso joint), then final sharpening... Still not totally satisfied with the profile, especially at the tip. but I am hesitant to mess with it more at this point.... THIS is the blade for which I constructed the wooden radius platen to create the Urasaki. Im not sure if the hand sanded satin finish is really needed, as the sharpening process, which appears to be particular to single bevel blades with a Ura, inherently leaves significant sharpening marks (top and bottom of the Ura side, and on the entire bevel on the single bevel side. Still - I am curious to see how the sharpening turns out - as the basic geometry and sharpening process is essentially that used for straight razors. All indicates are that a properly sharpened Yanagiba is SHARP.... (I might need to make a Saya for this one...)

(BTW - the curious thing about the last photo is that is *looks* like the right (as viewed in the photo) side of the blade is the bevel side .... but what you are actually looking at is the curvature of the Ura on that side (which would be the left side if you were looking down at the blade as you hold it), the other side (left side as viewed in the photo) is the flat of the single bevel - you actually do not see the shinogi or the flat)

(BTW - the curious thing about the last photo is that is *looks* like the right (as viewed in the photo) side of the blade is the bevel side .... but what you are actually looking at is the curvature of the Ura on that side (which would be the left side if you were looking down at the blade as you hold it), the other side (left side as viewed in the photo) is the flat of the single bevel - you actually do not see the shinogi or the flat)

Cushing, how tall is the blade at the heel? Most yanagiba are only around 1-1.24" tall at the heel for a 240mm blade. Here is a pic of a 240mm yanagiba I found online. It's around 29mm at the heel, 3.66mm thick. The spine of the yanagiba is an almost straight shallow slope down for the first half of the blade and then gradually gets steeper towards the tip. The edge profile looks good, yours just looks pretty tall for a yanagiba; its like a cross between a funayuki and a yanagiba?

- Joined

- Jun 3, 2019

- Messages

- 2,714

Cushing, how tall is the blade at the heel? Most yanagiba are only around 1-1.24" tall at the heel for a 240mm blade. Here is a pic of a 240mm yanagiba I found online. It's around 29mm at the heel, 3.66mm thick. The spine of the yanagiba is an almost straight shallow slope down for the first half of the blade and then gradually gets steeper towards the tip. The edge profile looks good, yours just looks pretty tall for a yanagiba; its like a cross between a funayuki and a yanagiba?

It is 1.5" at the heel. Honestly, i profiled this out so long ago that i dont remember where i got that dimension from. I would have looked at japanesechefsknives.com but looking there now, the knives posted agree with your stated range. To quote horesewright ... quien sabe... narrower would definitely look better.

This knife was always really intended to be a "trial run" towards ultimately making a 300 mm yanagiba - which is what i REALLY want , so im not going to cry about this one (it should still do a decent job...).

Yeah, it will cut well! Sometimes I struggle with blade shape/dimensions and getting it to "look" like I want it to! It's amazing what 1/4-3/8" will do in terms of profile! The yanagiba are strange to me being fatter and shorter height wise. I like a taller sujihiki myself, but it's harder to get the profile looking right.

Oh, AmeriBrade has 36" Radius hardened metal platens for $75, 6.75" hole pattern on center if you are still looking for a inexpensive radius platen Hoping to try mine out tomorrow!

Hoping to try mine out tomorrow!

Oh, AmeriBrade has 36" Radius hardened metal platens for $75, 6.75" hole pattern on center if you are still looking for a inexpensive radius platen

- Joined

- Jun 3, 2019

- Messages

- 2,714

Thank you Taz. I will check out what Ameribrade is selling! (my wooden one worked surprisingly well .... but it will definitely be lifetime limited. Still - I found it surprisingly easy to grind in the Ura, and to control how far towards the spine and edge it went. good luck with yours!Yeah, it will cut well! Sometimes I struggle with blade shape/dimensions and getting it to "look" like I want it to! It's amazing what 1/4-3/8" will do in terms of profile! The yanagiba are strange to me being fatter and shorter height wise. I like a taller sujihiki myself, but it's harder to get the profile looking right.

Oh, AmeriBrade has 36" Radius hardened metal platens for $75, 6.75" hole pattern on center if you are still looking for a inexpensive radius platenHoping to try mine out tomorrow!

- Joined

- Apr 13, 2017

- Messages

- 2,174

Here's a new recurve harpoon hunter in 5/32" 8670 with Olive scales, 9 3/4" OAL with a 5" Blade. It features blue G10 liners, crushed Red Opalite inlays and copper hardware.1 1/2 years ago I saw some guys trimming an olive tree and I grabbed a bunch of logs and thick limbs. A week later I scored a bunch of Mesquite but haven't used any yet. It doesn't take long to cure over 2 summers in the desert sun of Phoenix, moisture meter with minimum reading of 5% didn't register. I painted the ends to slow the cracking and it worked pretty well.

Here's the third recvurve bowie I made. The handle is special on this one because it is a piece of stabilized bog oak, but the voids in the wood have not just been filled with epoxy, but also with copper powder. It also has a bronze guard, paper micarta spacer and another bronze spacer with decorative fullers.

Next one is my kitchen buddy design. Just a small, practical 4 inch blade made from 14C28N. Handle is a paper micarta frame with stabilized walnut scales on both of them.

Next one is my kitchen buddy design. Just a small, practical 4 inch blade made from 14C28N. Handle is a paper micarta frame with stabilized walnut scales on both of them.

- Joined

- Mar 1, 2010

- Messages

- 1,027

Very nice! I especially like the copper powder in the Bog Oak. Nice touch.Here's the third recvurve bowie I made. The handle is special on this one because it is a piece of stabilized bog oak, but the voids in the wood have not just been filled with epoxy, but also with copper powder. It also has a bronze guard, paper micarta spacer and another bronze spacer with decorative fullers.

Next one is my kitchen buddy design. Just a small, practical 4 inch blade made from 14C28N. Handle is a paper micarta frame with stabilized walnut scales on both of them.

Forrest Taylor

Knifemaker / Craftsman / Service Provider

- Joined

- May 13, 2021

- Messages

- 371

I really like the handles on the bottom two. Look to be great for delicate work

Forrest Taylor

Knifemaker / Craftsman / Service Provider

- Joined

- May 13, 2021

- Messages

- 371

Cool idea on the holderHi everybody!

I want to show you my first kitchen set made for a dear friend!

@Moderator: If the post is not in the rigth area, feel free to delete it!

They are not perfect at ALL but I wil get better. Any suggestion is welcome!

Blades: stainless steel AISI420. 58 HRC

Handles: walnut + white spacers (the smaller one is made whit vineyard wood + brass spacers)

Knife holder: poplar

Last edited:

- Joined

- Mar 10, 2013

- Messages

- 1,074