- Joined

- Apr 3, 2011

- Messages

- 5,963

Very cool congratulations brother, much deserved

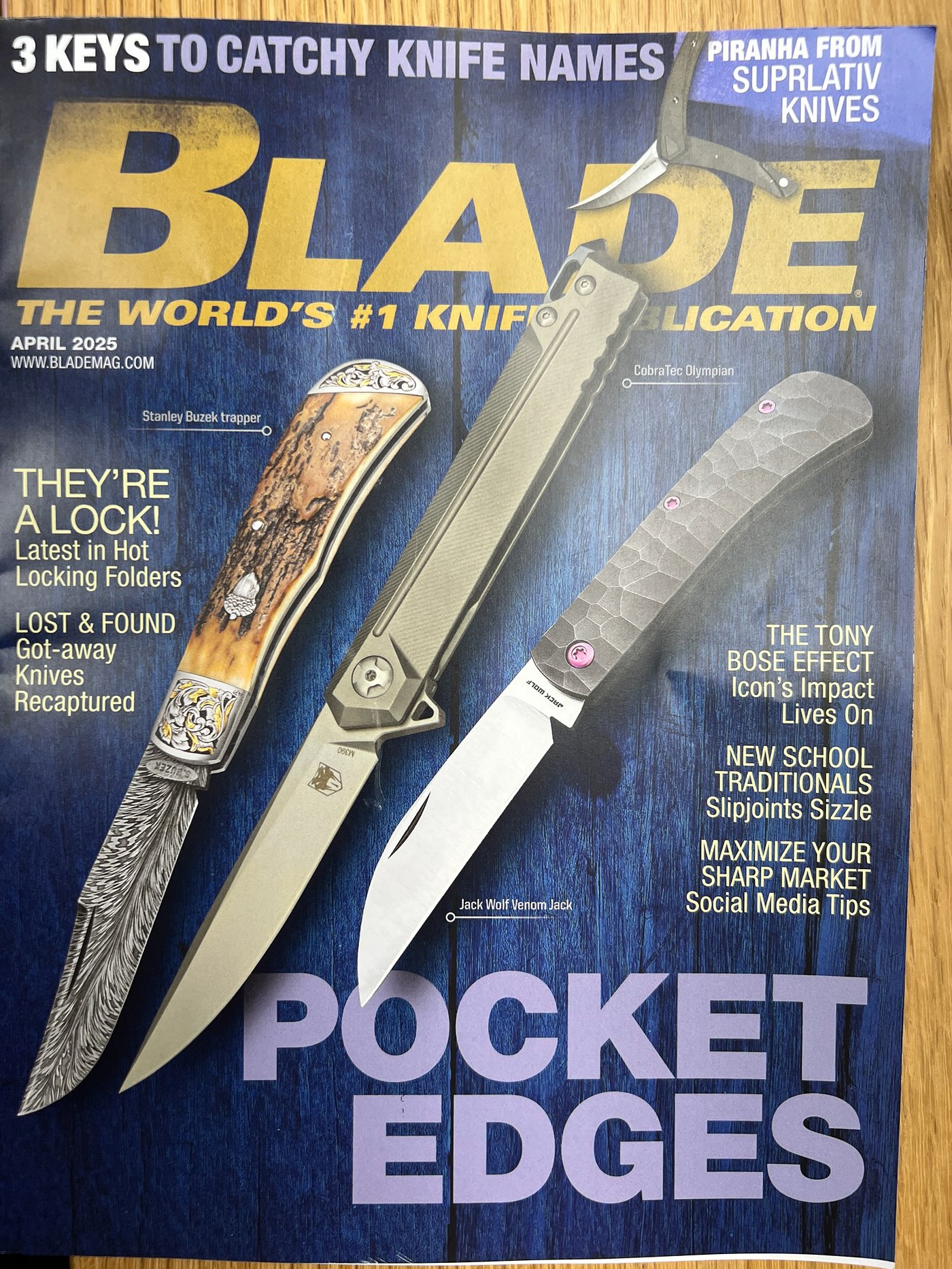

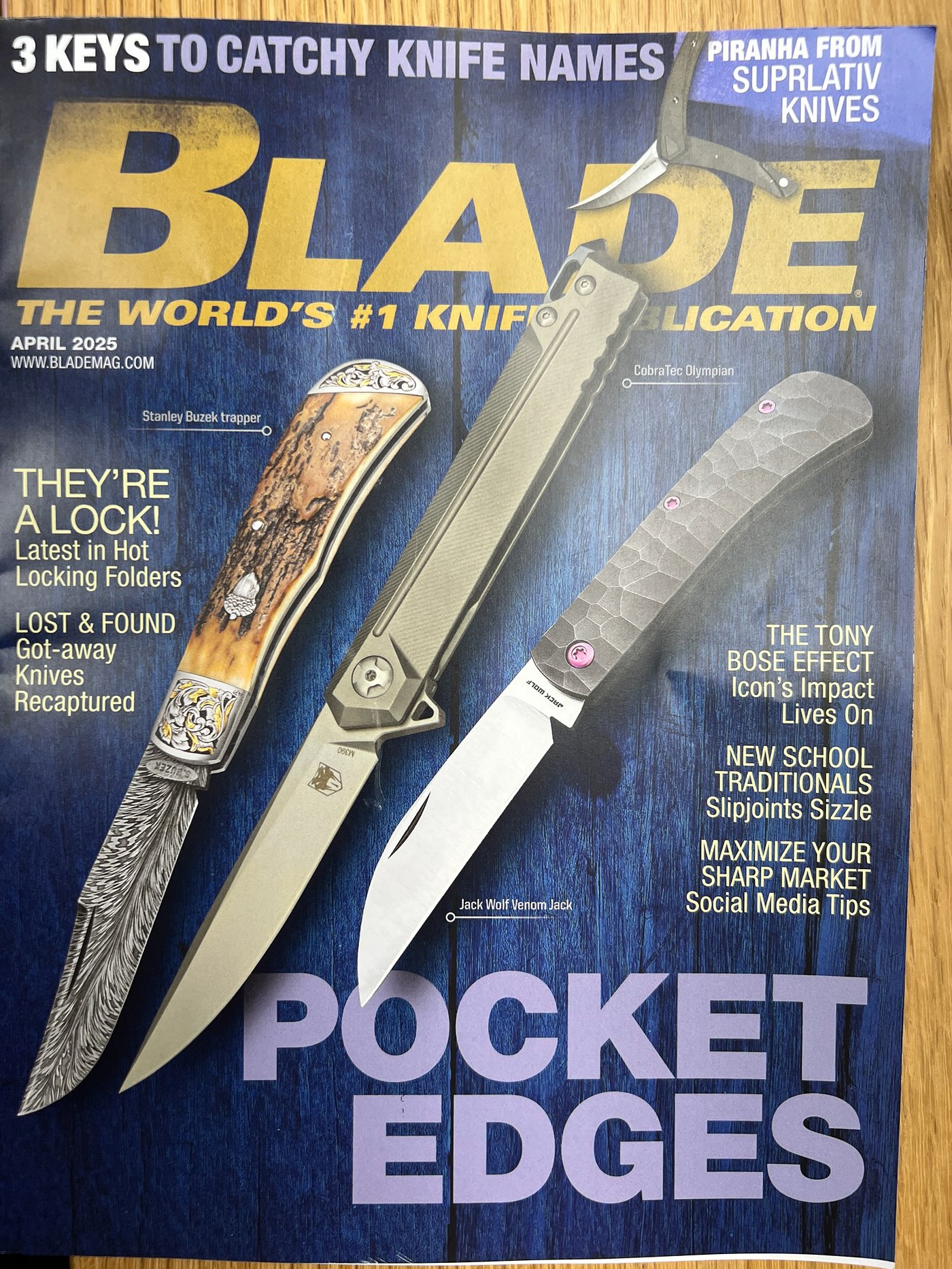

They put one of mine on the cover. Very happy.

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

Very cool congratulations brother, much deserved

They put one of mine on the cover. Very happy.

Update.(two weeks ago) I’ve made a hypothetical “functioning” wooden model prototype. It works in theory. Just need to make it out of steel.

Update today. Found some steel at a scrap yard. M42 tool steel. 15x5x2 blocks.

heavy stuff!! Going to try to shape it into the prototype.

Anyone have any idea what these monster blocks were used for? Guessing industrial cutting. Says “GT”? On the side.

The more I read up on it, the more I’m hesitant to cut it. I tested a small portion and it’s able to be cut (not easily but it’s doable)That might be a special find, I'm not sure if i would cut it up! Super high cobalt HSS, I have never even heard of it but it sounds exotic. If those are flat they might be of use as quench plates too but that might be a bad idea too... just saying that is a potentially cool find! It is likely going to be very difficult to work with, maybe try drilling in an inconspicuous spot to see if you even can.

EDIT ---> here you go https://knifesteelnerds.com/2019/12...ed-steels-maxamet-rex-121-and-more-explained/

I'd get some other steel... that's kind of always the answer and I was really trying to think of a way around it. It's not going to be fragile but it will be more fragile than it should be by far and just awful to work with. If you really want to use it for something smaller high hardness edc style blades would be better.The more I read up on it, the more I’m hesitant to cut it. I tested a small portion and it’s able to be cut (not easily but it’s doable)

The prototype calls for a slab of steel that’s 14x5x2. Could be any steel, just my luck that the only thing that fit the bill was something this interesting.

I’m not even sure if it would be good steel for the project given it’s already hardened.. I’m worried the hardness would prove brittle when formed into a spiked axe head.. what do you think? Would it be worth annealing or should I find another softer piece to work with?

An original piece, need a working prototype. But I have no forging equipment. No torch. Can’t melt it to pour into a mold. Also no mold..I'd get some other steel... that's kind of always the answer and I was really trying to think of a way around it. It's not going to be fragile but it will be more fragile than it should be by far and just awful to work with. If you really want to use it for something smaller high hardness edc style blades would be better.

2" thick? Is it an art piece or recreation of something? 2" is really thick. I just made some war hammers that are 3/8" and lean... almost too much for the average user weight wise.

This sounds cool!

wow!Finished up on Sharknivco Saturday! I had a lot of fun with this "Waka", now it's off to @SharpByCoop for glamor shots!