- Joined

- Mar 10, 2011

- Messages

- 2,697

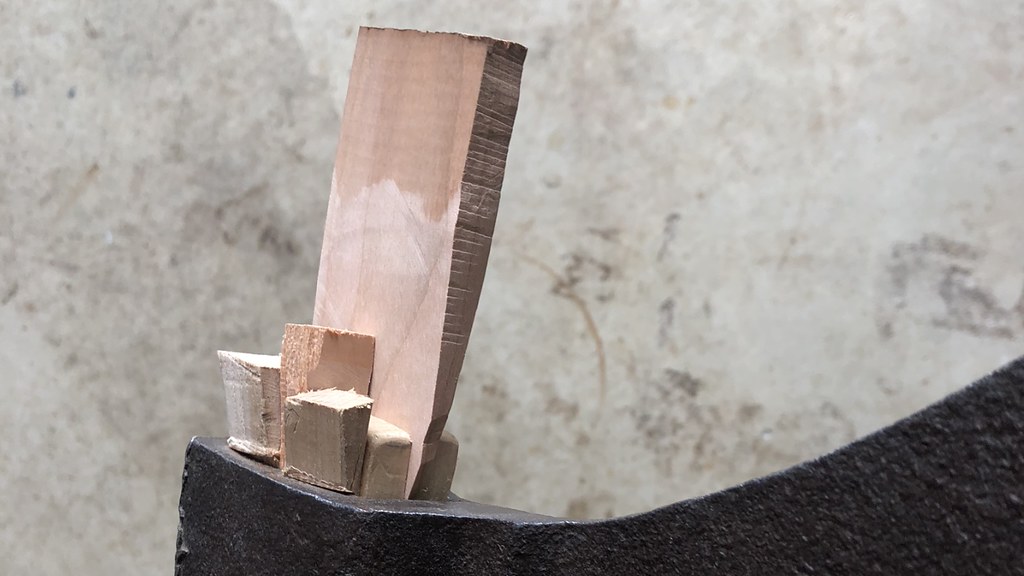

Interesting discussion about proud vs flush. I have some thoughts but no real conclusions. First a question. Suppose you were given the axe below cut proud about 1/4-3/8". It's rock solid after 20+ hours of hard use. Unfortunately, junior borrows it and leaves it in the driveway for the delivery man to run over and break the handle. No other part of the handle has any damage. You are going to replace the handle (after the talk with junior). You have virtually no tools but have a drift (scrap wood) and a hammer (or a rock) to drive the broken handle out. However, one tool you do have is a saw and you want to drive the broken handle out with the least effort. The question is: Do you drive it out as is or do you cut it flush, and then drive it out?

My inclination would be to cut it flush first, BUT I have never encountered this situation and I don't remember running across any information on what to do, so I have no idea - just my gut instinct (which along with $1.06 will get me a coffee at McDonald's).

Now, you may be thinking that because my gut is telling me that that handle would come out easier if cut flush that I think that a proud haft would have the potential to keep a head from flying off longer than a flush cut. I don't know how much, but that's what my gut tells me. I don't think it would necessarily keep the head tighter. Already mentioned is the humidity factor. Here in SW MI it can get quite humid in the summer and dry in the winter. Tool handles, wooden doors, you name it change quite a bit with the seasons and I don't think the flair of the handle over the top of the eye will help overcome that.

I also like the idea mentioned that leaving the haft proud will allow cutting the handle flush and not the wedge to gain purchase to pull the wedge. Again, no experience here.

As for my own hangs, I have done both. I can say that my preference is to use a saw to trim off the top of the handle and I don't like the idea of my saw blades contacting an axe head.

The above are just my thoughts. If you've got this far in the post thanks for reading.

Bob

My inclination would be to cut it flush first, BUT I have never encountered this situation and I don't remember running across any information on what to do, so I have no idea - just my gut instinct (which along with $1.06 will get me a coffee at McDonald's).

Now, you may be thinking that because my gut is telling me that that handle would come out easier if cut flush that I think that a proud haft would have the potential to keep a head from flying off longer than a flush cut. I don't know how much, but that's what my gut tells me. I don't think it would necessarily keep the head tighter. Already mentioned is the humidity factor. Here in SW MI it can get quite humid in the summer and dry in the winter. Tool handles, wooden doors, you name it change quite a bit with the seasons and I don't think the flair of the handle over the top of the eye will help overcome that.

I also like the idea mentioned that leaving the haft proud will allow cutting the handle flush and not the wedge to gain purchase to pull the wedge. Again, no experience here.

As for my own hangs, I have done both. I can say that my preference is to use a saw to trim off the top of the handle and I don't like the idea of my saw blades contacting an axe head.

The above are just my thoughts. If you've got this far in the post thanks for reading.

Bob