- Joined

- Aug 21, 2013

- Messages

- 3,898

Oh Jill...

The BladeForums.com 2024 Traditional Knife is ready to order! See this thread for details:

https://www.bladeforums.com/threads/bladeforums-2024-traditional-knife.2003187/

Price is $300 $250 ea (shipped within CONUS). If you live outside the US, I will contact you after your order for extra shipping charges.

Order here: https://www.bladeforums.com/help/2024-traditional/ - Order as many as you like, we have plenty.

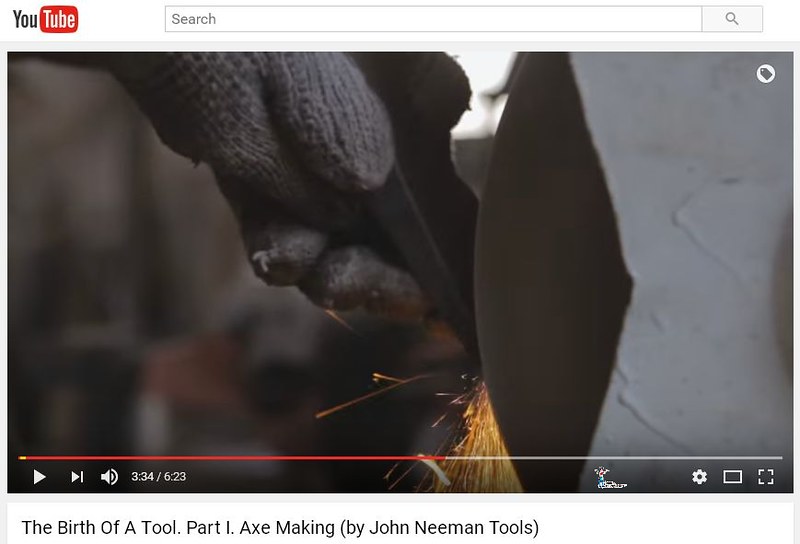

It was the first one I clicked on.Oof. That's not the worst video with a bench grinder I've seen but it sure isn't great. This isn't with an axe and he's light on the details, but this isn't too bad of a video on grinding thin-edged tools with a bench grinder. Note how he specifically states to use a friable wheel and he uses a very light touch and keeps the tool moving.

http://www.bladeforums.com/threads/what-did-you-sharpen-today.1318350/page-6#post-16431877. . .

------------------------------------------------------------------

Axe:

Plane iron:

Chisel:

If you have no experience and skill for the job, then know your limits and stay away.

Those that can, do.

Those that can't burn their tools and tell others its bad.

There is more then one way to do something.

Not telling anyone to run out and get a bench grinder.

Nope.

However, a 1x30 from harbor freight and some Norton Blaze belts will make your life easier and get ya swinging faster if you know what you are doing.

I'd be delighted to give that baby a refurb and do a step-by-step photo/possibly video series with it and send it back to ya' ready to hang.

Those Dynamics are real little gems.

I am guessing that you want to know if there is a change, so if any testing is done, then both before and after.You should send it out for a hardness test after.

I am guessing that you want to know if there is a change, so if any testing is done, then both before and after.

Bob

Edit:too late.