Don't you think that most of this discussion is purely intellectual? I could stab all of you to death with a 10 in nail that I bought at the hardware store for 50 cents. Or beat you to death with a rock! I believe that all of us here LOVE knives, otherwise we wouldn't be here. I'm not sure that there is any "perfect" knife or steel. Ya but they keep coming up with stuff that is better & better. Do I really NEED the $200 or $400 or $1000 0r $10,000 knife I just bought NO I just like all of you just like them & wish to own or posses them. Just because we can!

-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Buck 110 in Bos 5160

- Thread starter Navod

- Start date

Duane Sanders

BANNED

- Joined

- Sep 13, 2015

- Messages

- 189

Sorry guys. I'm not seeing much in the way of action to get a real answer from either of you.

When buck answers me I will let you know. Until then stop with the assumptions on who is doing the thinking. Just like the last thread, I refuse to sit here and Just think. When we get the answer we will all see it, just like the last time.

When buck answers me I will let you know. Until then stop with the assumptions on who is doing the thinking. Just like the last thread, I refuse to sit here and Just think. When we get the answer we will all see it, just like the last time.

- Joined

- Jun 5, 2012

- Messages

- 29,333

So you don't believe there is a better steel than 5160 for a knife? or buck would use it right?

just for clarity...

just for clarity...

Sorry guys. I'm not seeing much in the way of action to get a real answer from either of you.

When buck answers me I will let you know. Until then stop with the assumptions on who is doing the thinking. Just like the last thread, I refuse to sit here and Just think. When we get the answer we will all see it, just like the last time.

Duane Sanders

BANNED

- Joined

- Sep 13, 2015

- Messages

- 189

Got to agree with you on that issue ! It is the MOST copied & HOTRODED as in customized hand gun ever! You bet I own one!! Mildly customized, trigger job, ambi safety, sights.

Is that legal in Canada?

Duane Sanders

BANNED

- Joined

- Sep 13, 2015

- Messages

- 189

So you don't believe there is a better steel than 5160 for a knife? or buck would use it right?

just for clarity...

No. I don't assume to know more than buck on how to make knives.

It's safe to say you've never used one of their Bos heat treated 420HC blades on a regular basis daily. If you did you would quickly disregard "better" steels. Not based on cost, name or brand, but on how well they do work, retain an edge with no damage like rolls, chips or cracks. I'm not the only one to notice how good they know how to heat treat steel. There is so much more to a knife than steel alone. After some regular use you learn that pretty quick. That I can not help you with.

Sure you just have to belong to a gun club. That is the hoop that you have to jump through. You have to apply and be on probation for 3 months and if they[the club members] have no problems with you you become a member and you can apply for a handgun license which you will get if you do not have any violent criminal convictions, violent criminal background or pending charges.

- Joined

- Jun 5, 2012

- Messages

- 29,333

wrong, I have use pauls 420 hc. yes it cuts just like other steels and sharpens well.

What the hell are you talking about you don't assume to no more than buck about making knives?

you said "if buck could make a better knife out of 52100 they would"... well what about the other steels that out perform 52100 and 5160.. why don't they use them?

is 5160 better than them as well?

clear answers please.

sure seems you are either VERY unaware of advanced steels being produced or are choosing to be ignorant of them.

ill say it again, 5160 is not the best at ANYTHING and its not the best at balancing edge retention, toughness, edge stability, lateral strength or any other categories.

it comes off like your saying 5160 is better than all other knife steels because buck uses it?

What the hell are you talking about you don't assume to no more than buck about making knives?

you said "if buck could make a better knife out of 52100 they would"... well what about the other steels that out perform 52100 and 5160.. why don't they use them?

is 5160 better than them as well?

clear answers please.

sure seems you are either VERY unaware of advanced steels being produced or are choosing to be ignorant of them.

ill say it again, 5160 is not the best at ANYTHING and its not the best at balancing edge retention, toughness, edge stability, lateral strength or any other categories.

it comes off like your saying 5160 is better than all other knife steels because buck uses it?

No. I don't assume to know more than buck on how to make knives.

It's safe to say you've never used one of their Bos heat treated 420HC blades on a regular basis daily. If you did you would quickly disregard "better" steels. Not based on cost, name or brand, but on how well they do work, retain an edge with no damage like rolls, chips or cracks. I'm not the only one to notice how good they know how to heat treat steel. There is so much more to a knife than steel alone. After some regular use you learn that pretty quick. That I can not help you with.

Last edited:

- Joined

- Jun 16, 2003

- Messages

- 20,207

5160 is a great choice for a chopper.

- Joined

- Jun 5, 2012

- Messages

- 29,333

Buck is not a small timer. If 52100 was the best option they would use it. The best steel will produce less customer complaints, better knives and less warranty work. There is much more to it than initial cost or what's on hand, especially with a company that can afford to use the best steel option.

I quoted you for posterity, right here you clearly imply buck uses the best steel option and if there was a better steel they would use it.

- Joined

- Nov 9, 2009

- Messages

- 44,314

No. I don't assume to know more than buck on how to make knives.

It's safe to say you've never used one of their Bos heat treated 420HC blades on a regular basis daily. If you did you would quickly disregard "better" steels. Not based on cost, name or brand, but on how well they do work, retain an edge with no damage like rolls, chips or cracks. I'm not the only one to notice how good they know how to heat treat steel. There is so much more to a knife than steel alone. After some regular use you learn that pretty quick. That I can not help you with.

Maybe you should read the question that was asked instead of answering something no one asked. Another thing, your responses are pretty inflexible, yet peppered with a whole lot of "I don't knows". A lot changes in in the world of metallurgy. Paul Bos is one of the best, if not the best heat treater in the world, no one is disputing that aspect. Your snarky responses are not really furthering the discussion, rather taking it further into the wrong direction, and all for what? Is there a prize at the end of this discussion no one has mentioned? Tone is down and you might actually learn something yourself, surely you cannot be here to simply "teach us all how it is", that would be something from someone that is all hat and no cattle.

- Joined

- Oct 17, 2015

- Messages

- 11,466

Living just a few miles from bucks factory, I love those people. If they built a 200 limited run of a different steel it was just because. Buy one enjoy it and the people who stand behind it. I will buy one tomorrow if any are available.

Cobalt

Platinum Member

- Joined

- Dec 23, 1998

- Messages

- 17,908

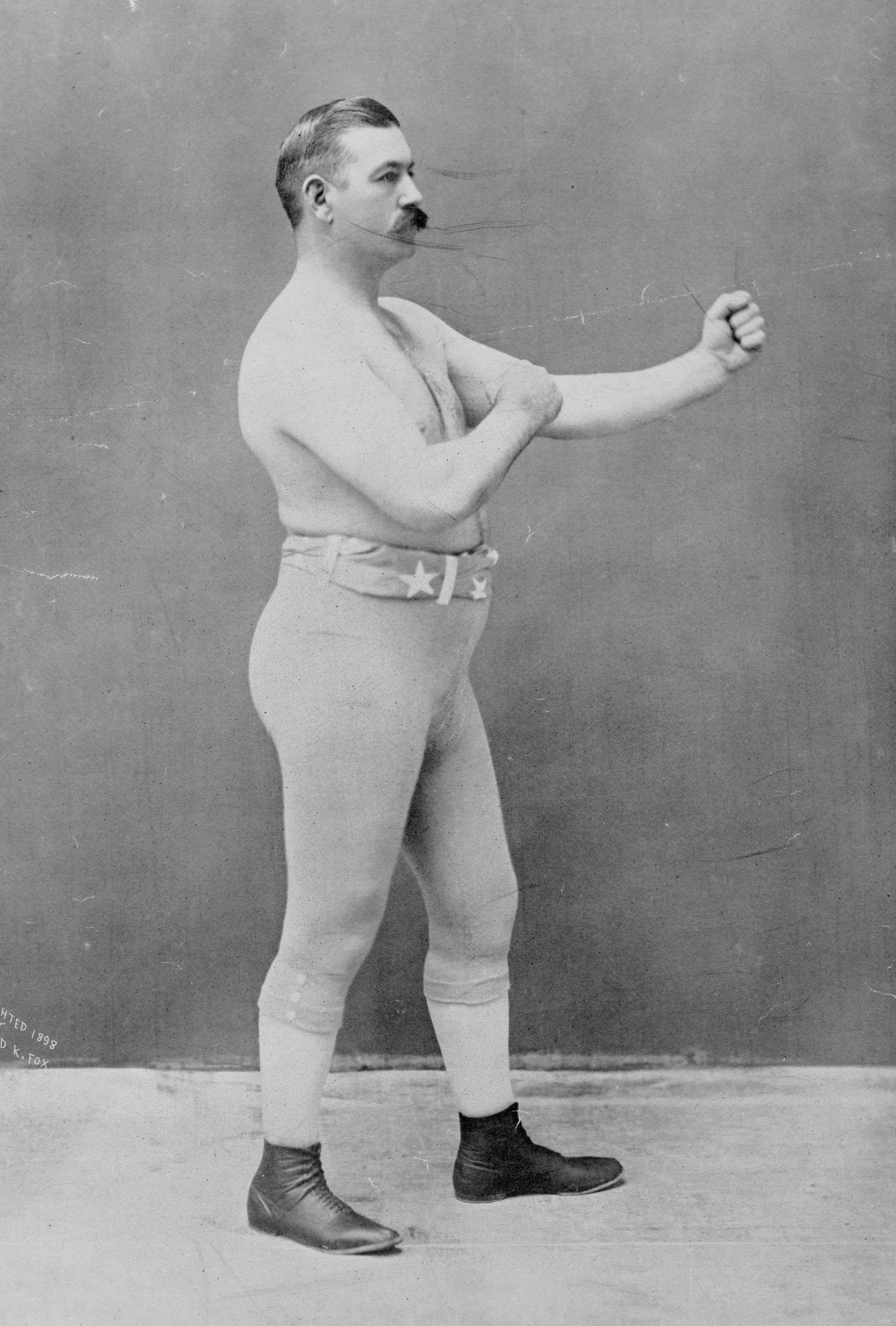

this is surely what it feels like in this thread.

Cobalt

Platinum Member

- Joined

- Dec 23, 1998

- Messages

- 17,908

Buck will warranty each and every Buck knife to be free of defects in material and workmanship for the life of the knife, and will repair or replace with a new Buck knife, at their option, any Buck knife that is defective. Buck Knives does not warrant its products against normal wear or misuse. Buck Knives are not intended to be used as hammers, chisels, pry bars or screwdrivers. If your knife was damaged due to misuse, Bucks repair department can analyze the damage and repair it for a reasonable fee.

The 110 certainly qualifies as a cutting tool, not a hammer prybar or screwdriver.

This is why Buck uses 5160

5160 isn't any where near the best steel for this:

and that is what the 110 is used for, get it? Which is why all of the other steels mentioned in this thread are a better fit for the 110. I'd rather have ATS-34 and 440C than 5160 in a 110.

- Joined

- Jun 5, 2012

- Messages

- 29,333

Hmm... so because 5160 performs adequately in a large fixed blade, its great for a folder? Ok

The buck 110 folder is NOT a hard use folder, its pinned together and would develop play if used to pry, or otherwise put through tasks more modern folders could shrug off.

The 110 is a fine folder, and has served many folks well for many years, those folks usually cut and peeled and sliced with it.

What is 5160's major attribute or claim to fame? Edge retention? No sir, its toughness.

What exactly do you do with your 110 that needs a truck leaf spring steel, over a more suitable steel that caters to the 110's main purpose i.e cutting, slicing, peeling, skinning.

The buck 110 folder is NOT a hard use folder, its pinned together and would develop play if used to pry, or otherwise put through tasks more modern folders could shrug off.

The 110 is a fine folder, and has served many folks well for many years, those folks usually cut and peeled and sliced with it.

What is 5160's major attribute or claim to fame? Edge retention? No sir, its toughness.

What exactly do you do with your 110 that needs a truck leaf spring steel, over a more suitable steel that caters to the 110's main purpose i.e cutting, slicing, peeling, skinning.

5160 is a great steel, I am always stocked at how well my Buck Punk holds an edge trough a ton of wood work....for that use, 420HC it FAR behind, but if all your slicing is lettuce, of course no difference would be observed

Last edited:

- Joined

- Apr 21, 2006

- Messages

- 5,612

Like everyone else I'll just speculate.

IMO, Buck probably made the knives in 5160 because they were contracted to make them in oak and charcoal colored runs of, I believe, 200 each.

It might simply bethat is what the company who ordered it wanted. They paid for them so I'd guess they had some say. Being as Buck is working with 5160 already it might be that they wanted a non stainless steel that is easy to sharpen, performs well and doesn't cost all that much compared to some higher priced steels.

People have asked Buck for a run of carbon steel folders for years. If I was contracting out for something exclusive for my shop I might have gone that way, or not. Can't say. I will say they look great and I want one. The Oak in particular.

Joe

IMO, Buck probably made the knives in 5160 because they were contracted to make them in oak and charcoal colored runs of, I believe, 200 each.

It might simply bethat is what the company who ordered it wanted. They paid for them so I'd guess they had some say. Being as Buck is working with 5160 already it might be that they wanted a non stainless steel that is easy to sharpen, performs well and doesn't cost all that much compared to some higher priced steels.

People have asked Buck for a run of carbon steel folders for years. If I was contracting out for something exclusive for my shop I might have gone that way, or not. Can't say. I will say they look great and I want one. The Oak in particular.

Joe